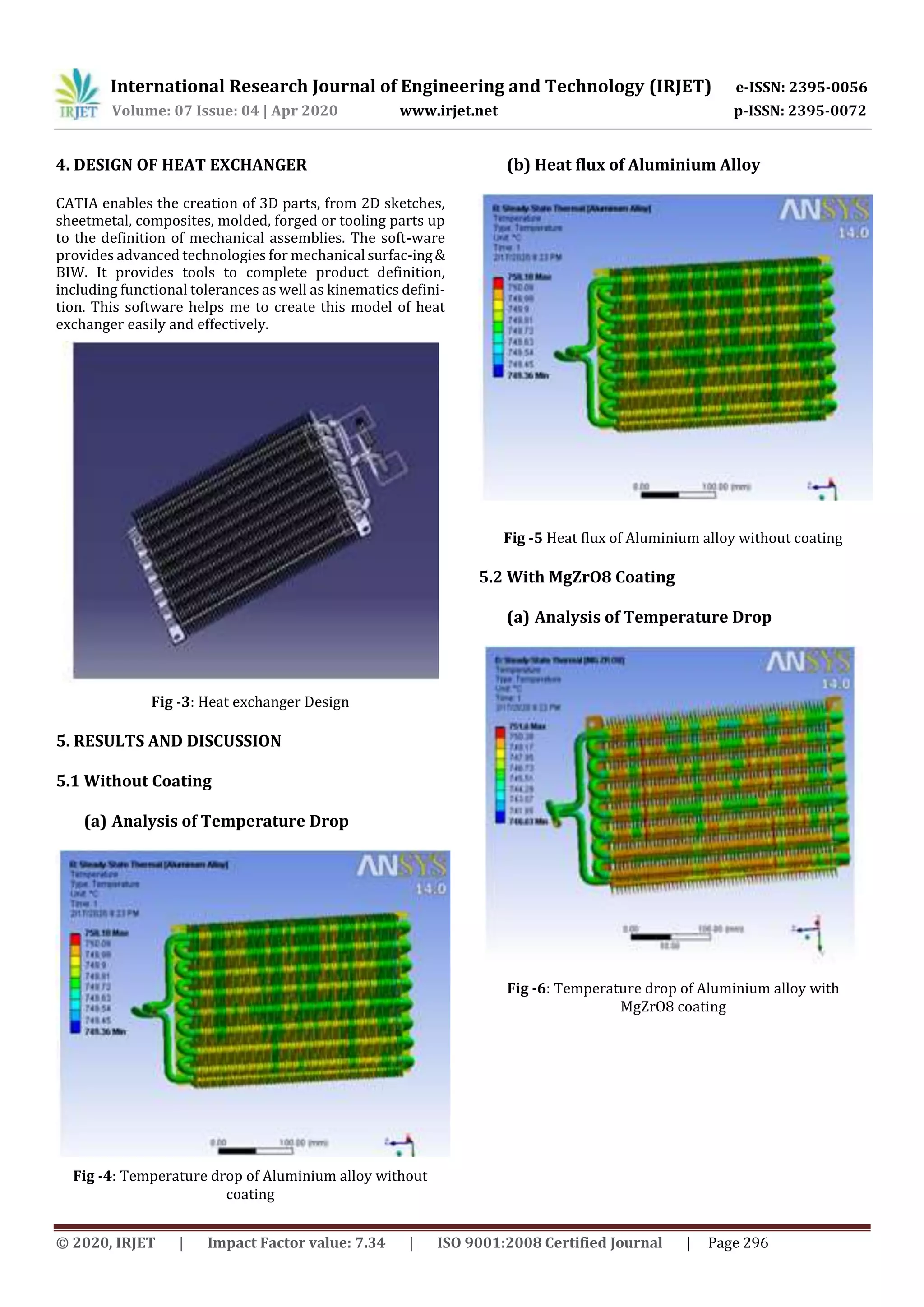

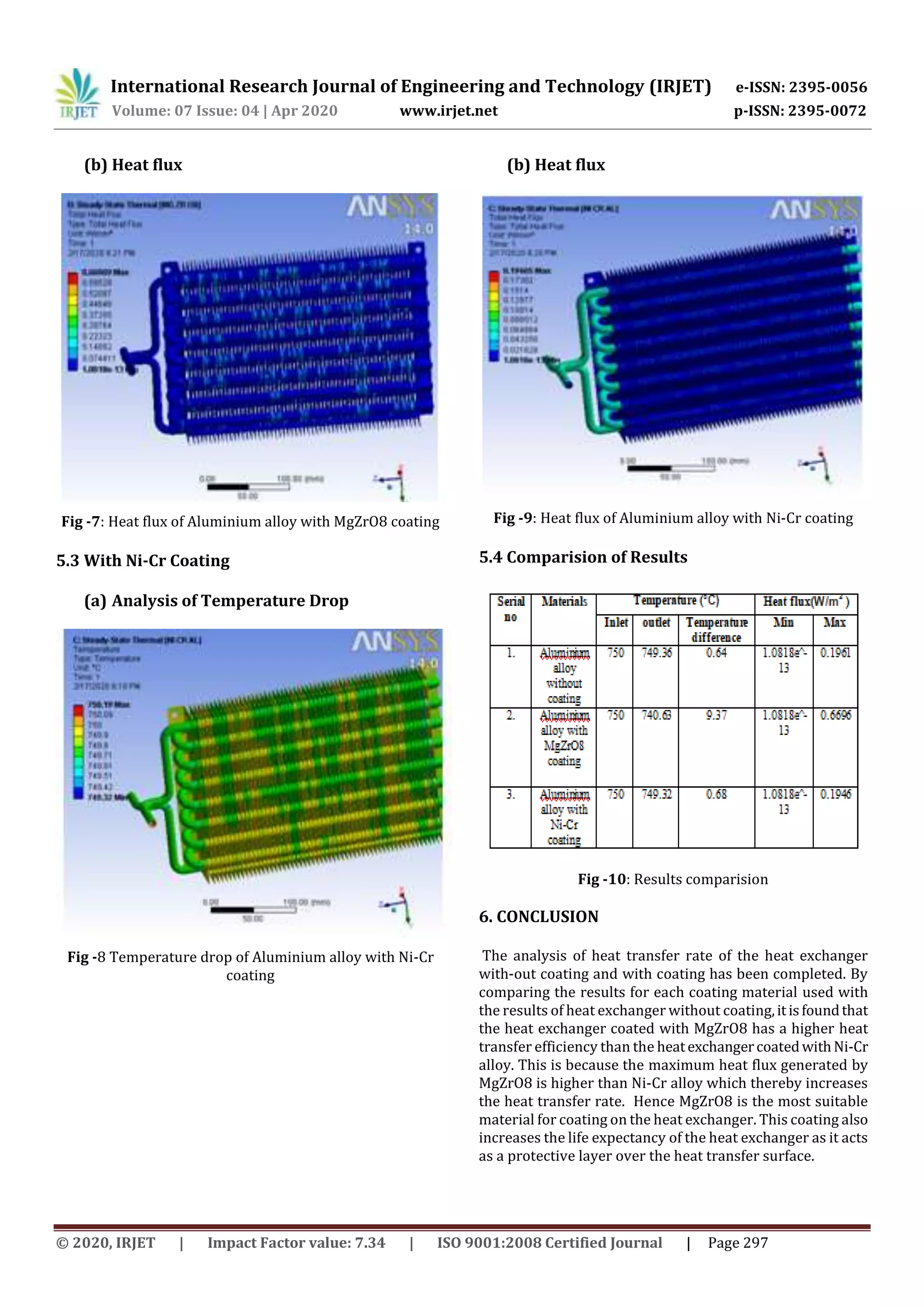

The document discusses designing and analyzing a heat exchanger with nano coating. It aims to determine which of two materials, magnesium zirconium oxide or nickel chromium alloy, is better suited for nano coating on a heat exchanger surface to increase heat transfer rate. The coating process involves blasting the surface followed by thermal spray application of the nano material. Properties of both materials are provided. The heat exchanger design is created using CATIA software. Analysis will be done using ANSYS to find the most suitable coating material.

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 07 Issue: 04 | Apr 2020 www.irjet.net p-ISSN: 2395-0072

© 2020, IRJET | Impact Factor value: 7.34 | ISO 9001:2008 Certified Journal | Page 298

REFERENCES

[1] R.S.Kumar,A.J.D.Nandhakumar,S.Prabhu,“Analysisof

naturalconvectiveheattransferofnano-coatedaluminiumfinsby

usingTaguchimethod,”JournalofHeatandMassTransfer,vol.49,

no.1,pg.55-64,2013.

[2] A.Witry,M.H.Al-HajeriandA.A.Bondok,“CFDanalysisof

fluidflowandheattransferredinpatternedRoll-bondedaluminium

plateradiator,”inProc.AThirdInternationalConferenceonCFDin

theMineralsandProcessIndustries,Dec2003.

[3]. R. Sabarish, Dr. J. Hameed Hussain, S. K.Pravin Kumar,

S.Vignesh.“ExperimentalInvestigationofHeatTransferAnalysison

NanoGrapheneCoatedExtendedSurface”.

[4]. Thiam Wong, “Thermodynamic and heat transfer

propertiesofAl2O3”](https://image.slidesharecdn.com/irjet-v7i463-210126051723/75/IRJET-Design-and-Analysis-of-Heat-Exchanger-with-Nano-Coating-5-2048.jpg)