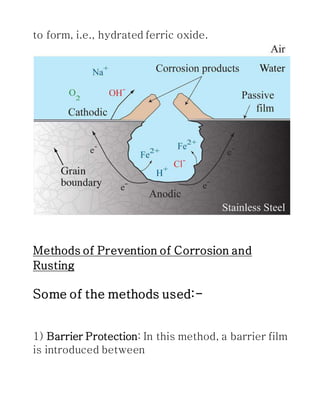

This document presents a student project on the effect of metal coupling on iron rusting. The student Mayank Chaudhary from JKG International School studied how coupling iron with more electropositive metals like zinc and magnesium prevents rusting, while coupling with less electropositive copper facilitates rusting. Through experimentation with iron nails wrapped in different metals, observation of color changes, and analysis, the student was able to conclude that metal coupling affects iron's corrosion, with more positive metals protecting iron and less positive metals increasing rusting.