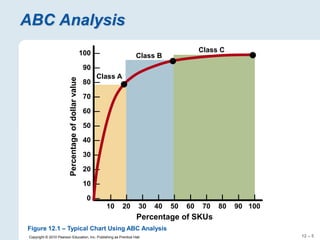

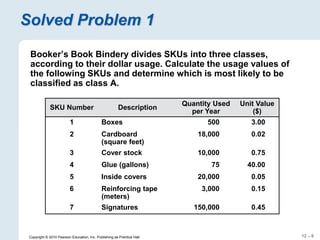

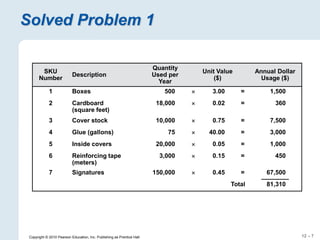

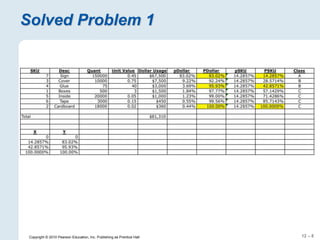

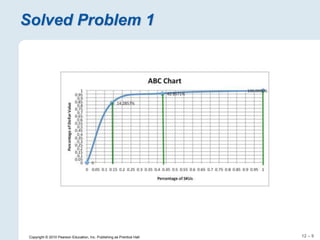

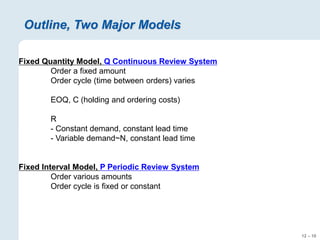

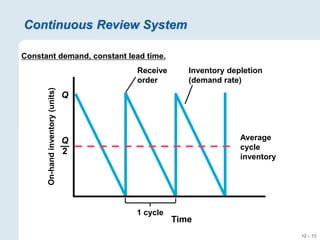

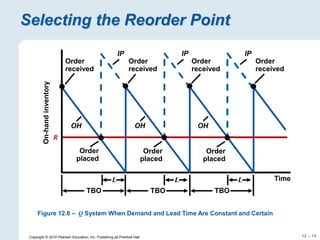

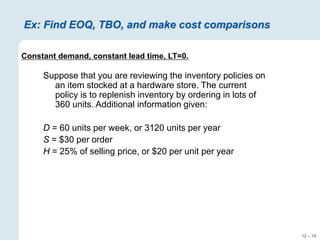

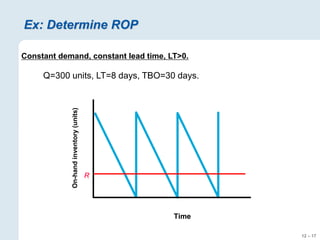

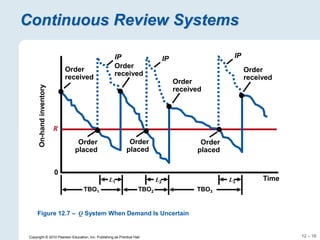

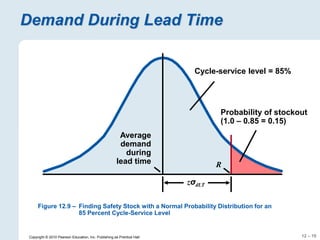

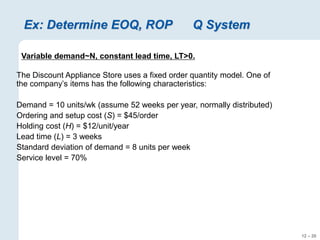

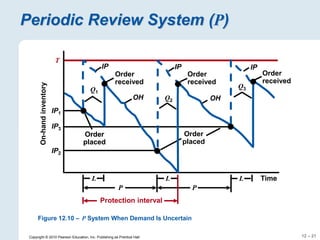

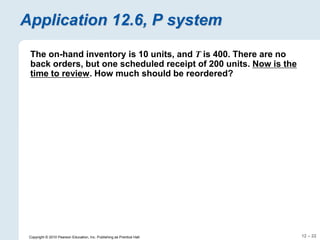

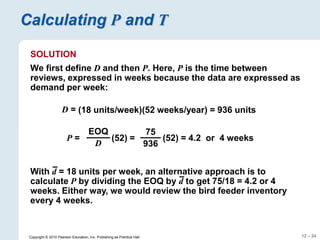

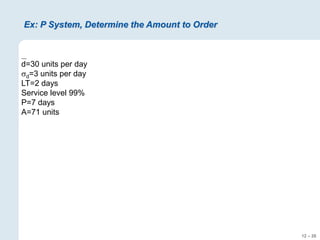

The document focuses on inventory management, covering concepts like inventory turnover, weeks of supply, and different inventory control systems such as the Q system and P system. It provides examples, calculations for reorder points, and safety stocks while comparing fixed quantity and fixed interval models. Additionally, it discusses ABC analysis to classify inventory based on usage value.