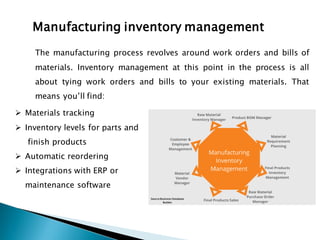

An inventory management system combines technology and processes to track stocked products throughout a company. Inventory management software provides a central database to analyze data, generate reports, forecast demand, and more. It features like barcoding, reporting, forecasting, alerts, and accounting tools. Manufacturing inventory management tracks materials and finished products using work orders, bills of materials, and automatic reordering. Warehouse inventory management focuses on item locations using advanced barcoding, multiple locations, shelf/bin tracking, and order picking. Retail inventory management prioritizes minimizing cash tied up in inventory using automatic reordering, forecasting, and barcoding to keep shelves full. Benefits include improved cash flow, reporting, storage costs, labor costs, dead stock