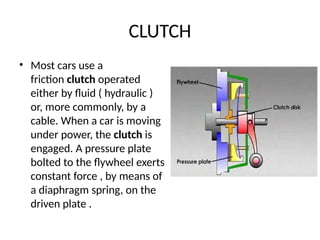

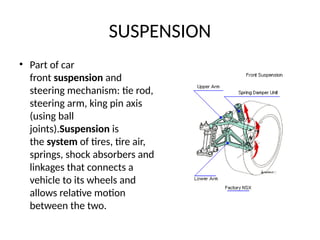

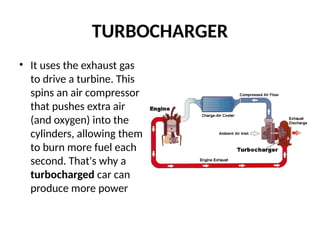

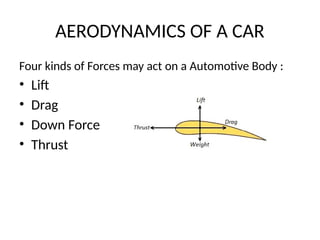

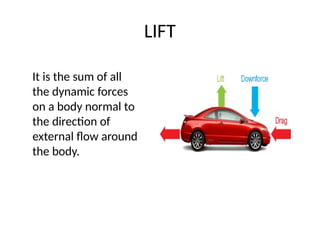

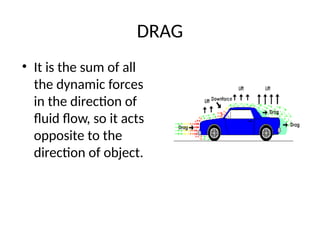

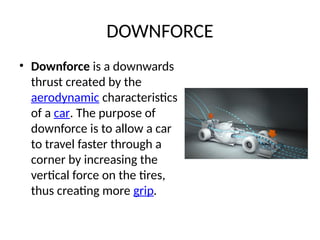

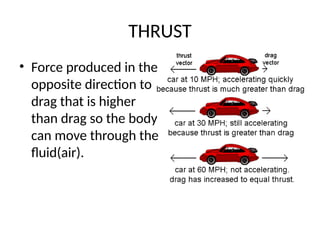

The document outlines essential safety protocols for automotive engineering labs, emphasizing the importance of personal protective equipment, reporting injuries, and cleanliness. It also provides an overview of vital automotive components such as spark plugs, clutches, and catalytic converters, detailing their functions and interrelationships. Lastly, it discusses the aerodynamic forces acting on vehicles, including lift, drag, downforce, and thrust.