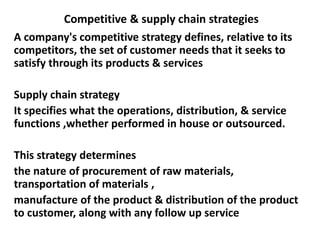

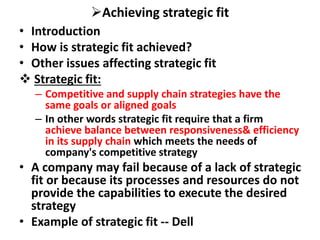

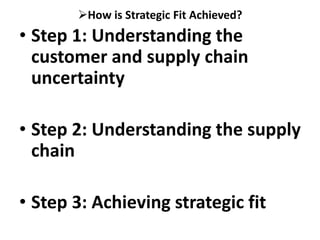

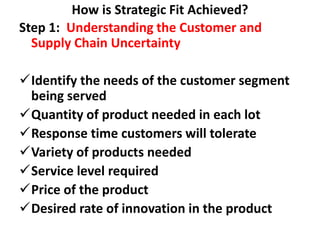

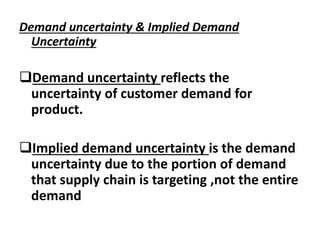

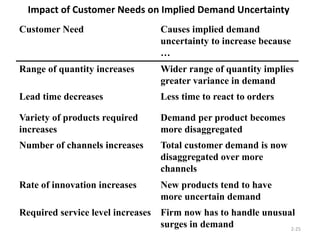

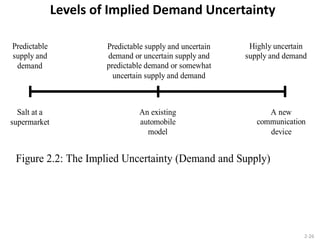

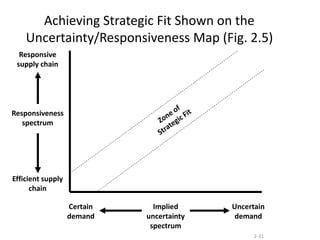

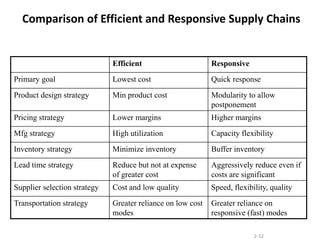

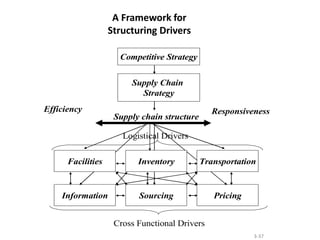

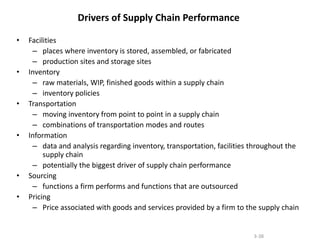

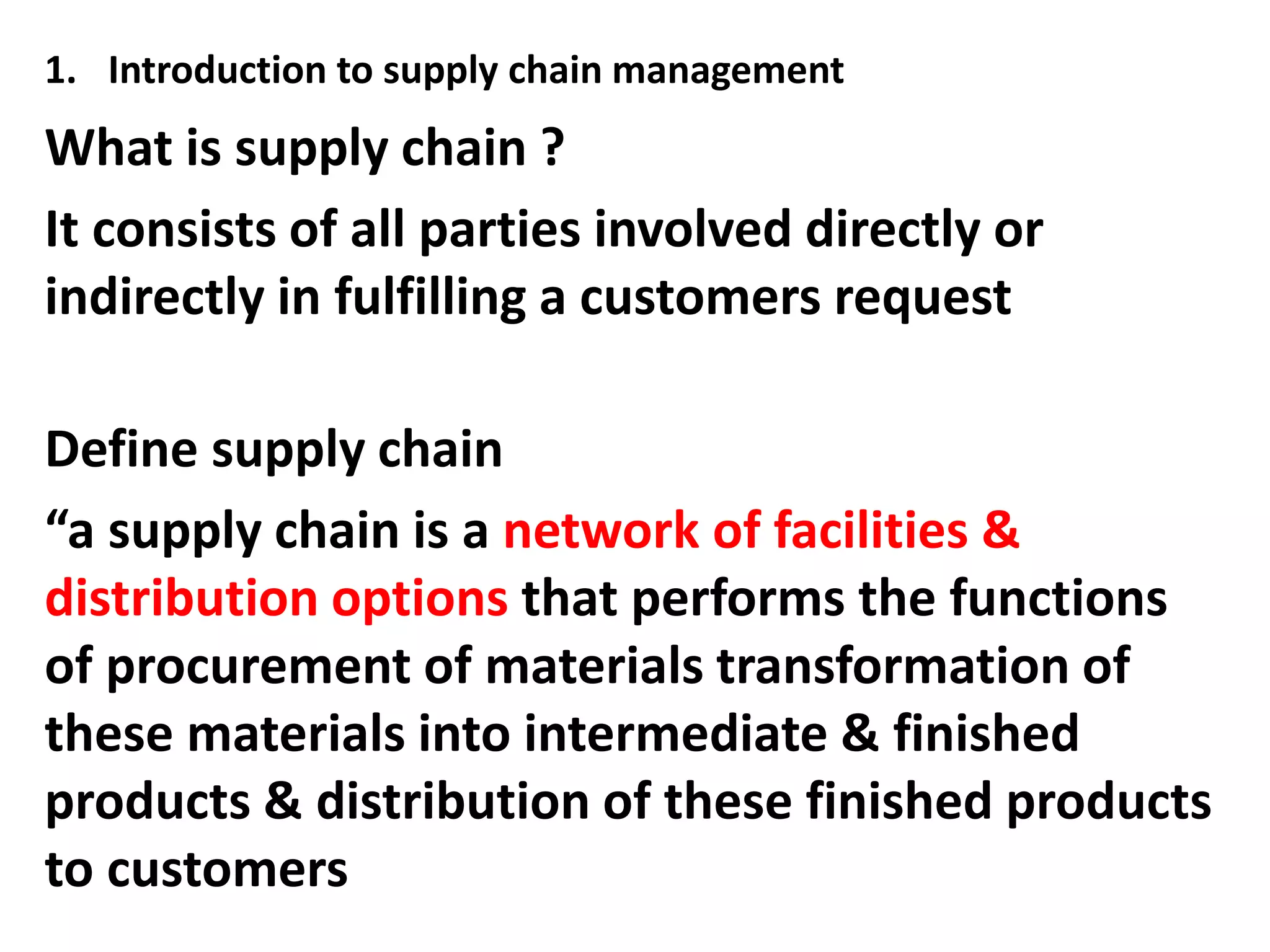

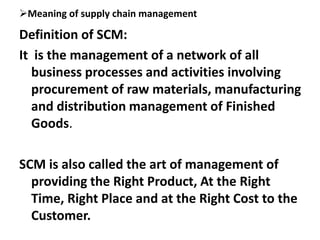

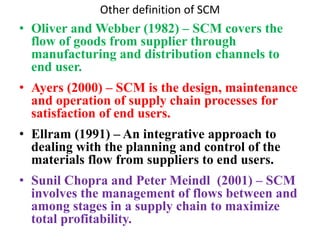

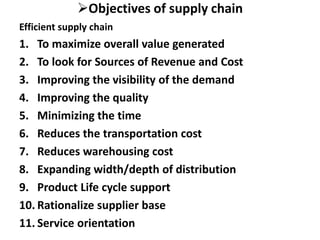

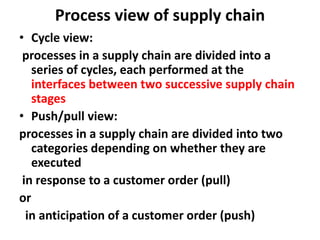

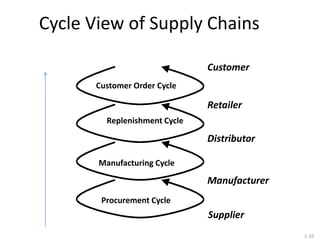

This document provides an introduction to supply chain management. It defines supply chain as a network of facilities and distribution options that procures materials, transforms them into products, and distributes products to customers. Supply chain management (SCM) is defined as the management of business processes involving procurement, manufacturing, and distribution to deliver the right product to the customer at the right time and cost. SCM aims to maximize overall value and looks for sources of revenue and cost reduction. Key decisions in SCM involve supply chain strategy, planning, and operations. The document also discusses push and pull processes in supply chains and how strategic fit is achieved between competitive and supply chain strategies.

![Supply Chain Management [SCM]

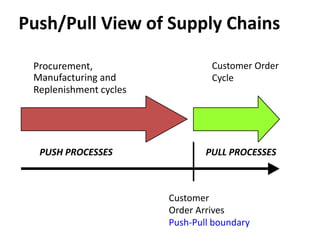

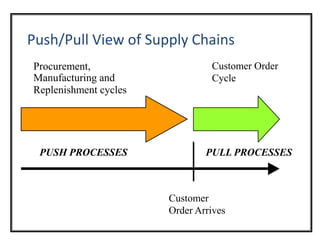

Customer Order

Cycle

Repl & Mfrg

Cycle

Procurement

Cycle

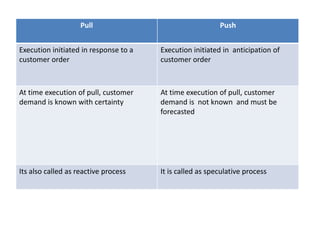

PUSH

Process

PULL

Process

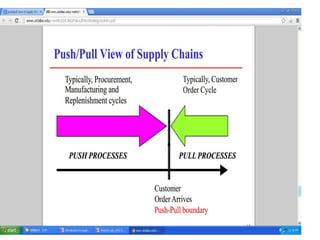

LL Bean

Cust Order & Mfrg

Cycle

Procurement

Cycle

PUSH

Process

PULL

Process

DELL

Customer order arrives

Customer order arrives

Process View of a Supply Chain: Push – Pull View](https://image.slidesharecdn.com/introductiontosupplychainmanagement-130223010333-phpapp01-201218061229/85/Introductiontosupplychainmanagement-17-320.jpg)