Sai Radha Developers is a real estate developer based in Udupi, India that has completed several residential projects and has ongoing projects. It aims to provide high-quality housing to middle-income families at affordable prices. Their ongoing projects include Sai Radha Pride J Wing, a residential tower with 56 units, and Sai Radha Nest 1 & 2, two residential complexes with a total of 115 and 68 units respectively. The company focuses on timely delivery, quality construction, and customer satisfaction.

![INTERNSHIP REPORT AKSHATHA B A

Dept. of Civil Engineering, KVGCE, Sullia (2016-17) Page 6

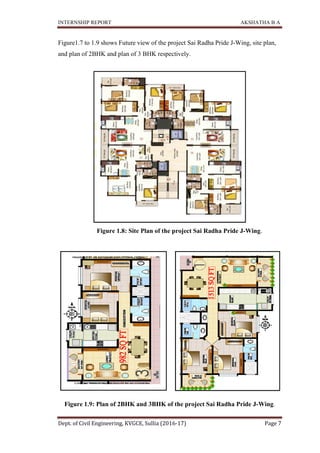

Details of project Pride J Wing are shown in Table 1.1.

Table 1.1: Details of Project Sai Radha Pride J Wing.

Project name SAI RADHA PRIDE J-WING

Total built-up area 5972 Sqft

Client Sai Radha Developers

Contractor Sai Radha Developers

Architect Anil Thakur

Structural consultants Shah Associates

Electrical consultants Shridhar Rao

Project start date 2011

Expected Project completion date 2016

Total cost Rs. 17,44,00,000

No. of towers 1[J]

Total no. of flats 56

2BHK 14

3BHK 42

Floors: Basement +G+14

Figure 1.7: Future view of the project Sai Radha Pride J-Wing.](https://image.slidesharecdn.com/internshipreportakku-200331053545/85/Internship-Report-Construction-Site-and-Office-Work-6-320.jpg)

![INTERNSHIP REPORT

Dept. of Civil Engineering, KVGCE, Sullia (2016

Figure 1.12 shows plan

shown in Table 1.2.

Figure 1.12: Plan of

Table

Project name

Total area

Total built

Client

Contractor

Architect

Structural consultants

Electrical consultants

Project start date

Expected Project completion date

Total cost

No. of towers

Total no. of flats

1BHK

2BHK

Floors:

INTERNSHIP REPORT

Dept. of Civil Engineering, KVGCE, Sullia (2016-17)

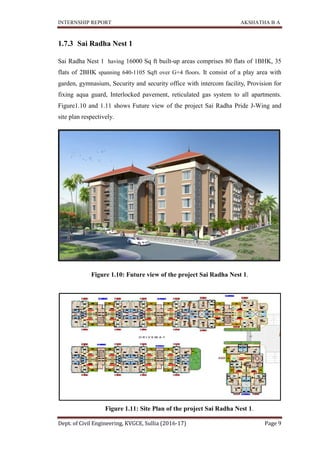

plan of 1BHK and 2 BHK. Details of project Sai Radha

: Plan of 1BHK and 2BHK of the project Sai Radha

able 1.2: Details of Project Sai Radha Nest 1

Project name SAI RADHA NEST 1

Total area 1.02 acres

Total built-up area 16000 Sq ft

Sai Radha Developers

Contractor Sai Radha Developers

Anil Thakur

Structural consultants Shah Associates

Electrical consultants Shridhar Rao

Project start date June 2015

Expected Project completion date Dec 2016

Total cost

No. of towers 6 [A, B, C, D, E & F]

Total no. of flats 115

80

35

G+4

AKSHATHA B A

Page 10

Details of project Sai Radha Nest 1 are

of the project Sai Radha Nest 1

Nest 1

NEST 1

Sai Radha Developers

Sai Radha Developers

Shah Associates

6 [A, B, C, D, E & F]](https://image.slidesharecdn.com/internshipreportakku-200331053545/85/Internship-Report-Construction-Site-and-Office-Work-10-320.jpg)

![INTERNSHIP REPORT

Dept. of Civil Engineering, KVGCE, Sullia (2016

Details of project Sai Radha Nest

1BHK, 2 BHK and 3 BHK

Table

Project name

Total built

Client

Contractor

Architect

Structural consultants

Electrical consultants

Project start date

Expected Project completion date

Total cost

No. of towers

Total no. of flats

1BHK

2BHK

3BHK

Floors:

Figure 1.15: Plan of

INTERNSHIP REPORT

Dept. of Civil Engineering, KVGCE, Sullia (2016-17)

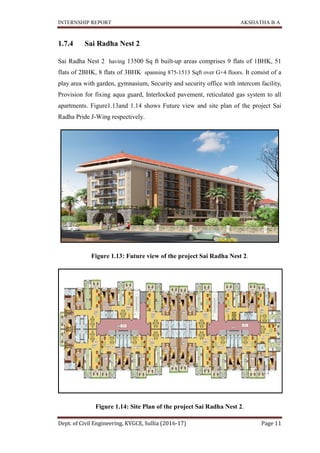

Details of project Sai Radha Nest 2 are shown in Table 1.3. Figure 1.15 shows

3 BHK of the project Sai Radha Nest 2.

Table 1.3: Details of Project Sai Radha Nest 2

Project name SAI RADHA NEST 2

Total built-up area 13500 Sq ft

Sai Radha Developers

Contractor Sai Radha Developers

Anil Thakur

Structural consultants Shah Associates

Electrical consultants Shridhar Rao

Project start date Jan- 2016

Expected Project completion date Dec 2016

Total cost 11,74,32,000

No. of towers 2 [G & H]

Total no. of flats 68

9

51

8

G+4

: Plan of 1BHK, 2BHK & 3BHK of the project Sai Radha

AKSHATHA B A

Page 12

Figure 1.15 shows plan of

2

NEST 2

Sai Radha Developers

Sai Radha Developers

Shah Associates

of the project Sai Radha Nest 2](https://image.slidesharecdn.com/internshipreportakku-200331053545/85/Internship-Report-Construction-Site-and-Office-Work-12-320.jpg)