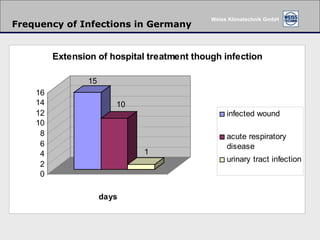

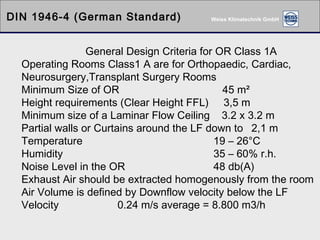

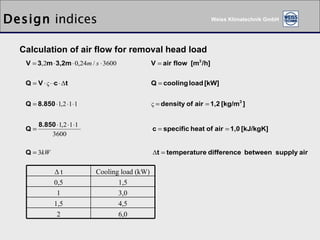

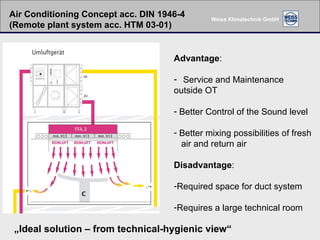

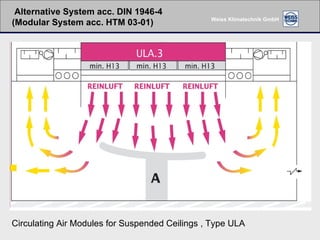

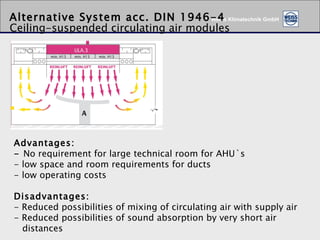

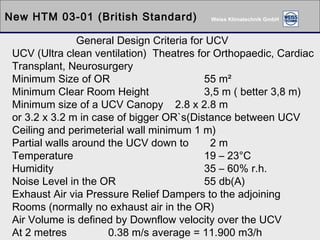

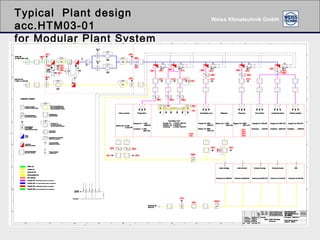

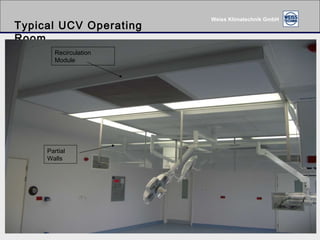

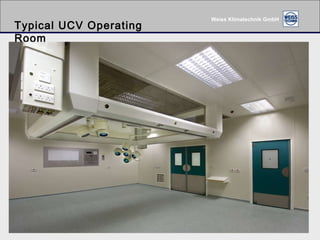

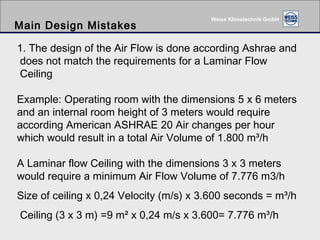

This document discusses international hygienic standards for operating rooms, including key details from standards like DIN, HTM, and ASHRAE. It highlights important design considerations like minimum room size, air volume, velocity, temperature and humidity requirements. It also notes common mistakes in design like not matching air flow to laminar flow ceiling needs or supply air temperature to internal heat loads. Adhering to standards properly requires integrated strategies across disciplines for optimal hygienic safety.