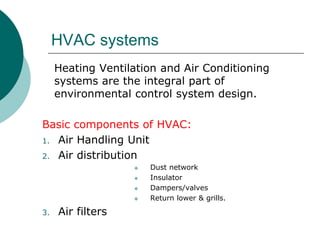

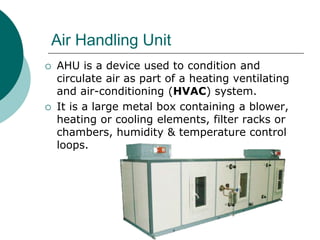

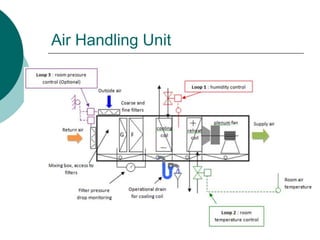

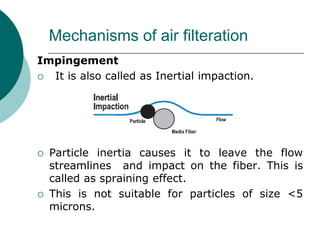

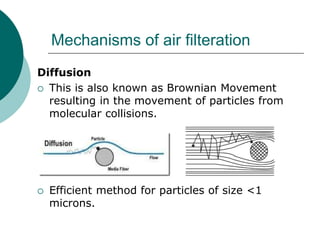

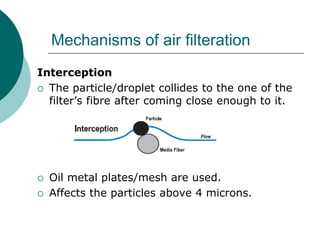

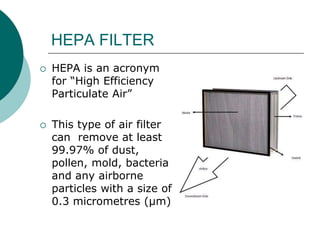

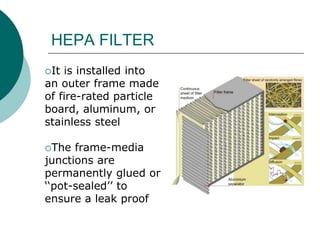

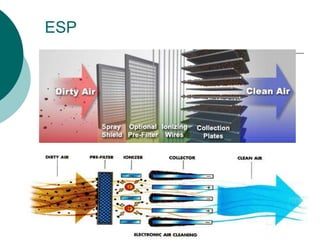

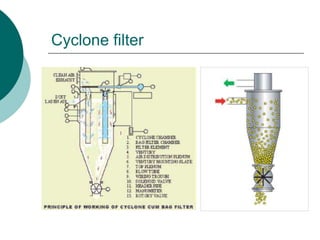

HVAC systems are an integral part of environmental control and include air handling units. AHU are large metal boxes that condition and circulate air, containing components like blowers, filters, and controls for temperature and humidity. Proper filtration is important for pharmaceutical facilities, utilizing filters like HEPA that can remove 99.97% of particles over 0.3 microns through mechanisms like impingement, diffusion, and interception. Dust collectors are also used to control air pollution and maintain clean environments through various collection methods. Regular inspection and maintenance of air handling systems is crucial to ensure quality pharmaceutical production.

![References

L.Lachman, The theory and practice

of industrial pharmacy

Bentleys textbook of pharmaceutics

Dust collectors – learning guide for

dust collectors [Internet]

Handbook of heating, ventilation &

air-conditioning.](https://image.slidesharecdn.com/airhandlingsystemsnew-140928235806-phpapp01/85/Air-handling-systems-new-40-320.jpg)