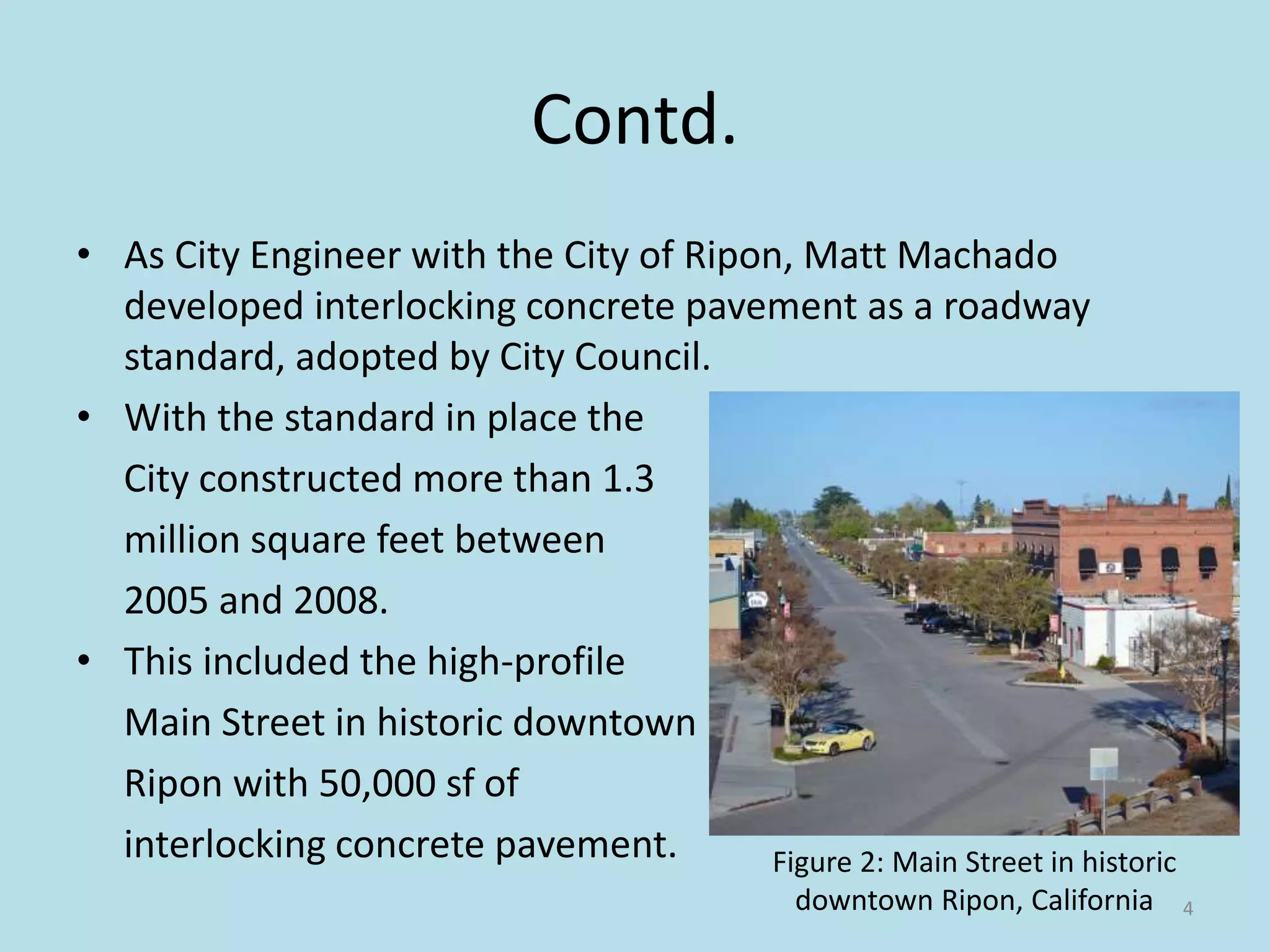

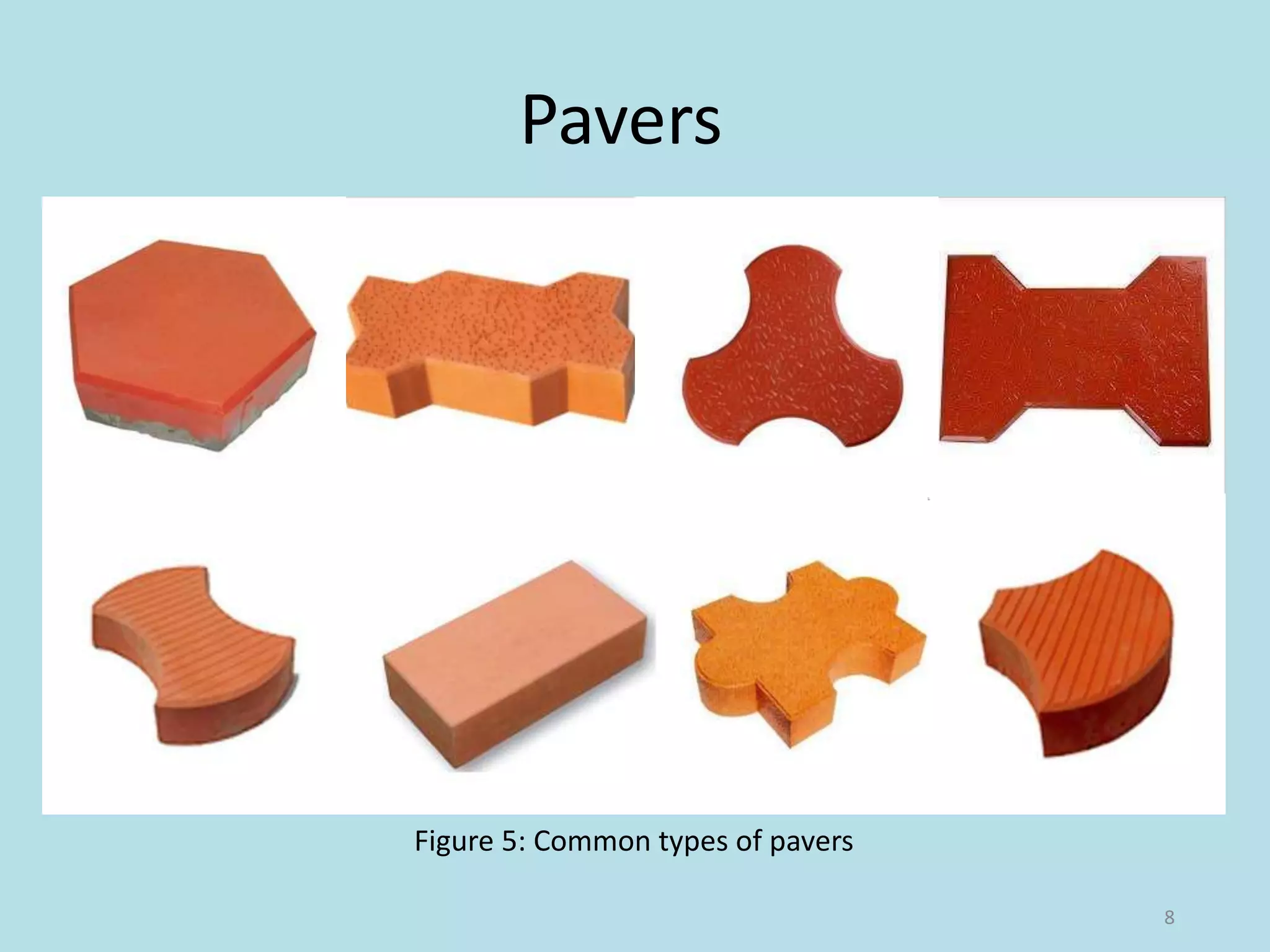

An early version of interlocking concrete pavement dates back to the Roman Empire in 312 BC. Interlocking concrete pavement (ICP) consists of solid concrete paving units called pavers with openings that allow water to infiltrate. The pavers are placed on an open-graded aggregate base and subbase to store and infiltrate water. ICP provides benefits like permeability for stormwater management, durability lasting over 30 years, and easy repair of individual units.