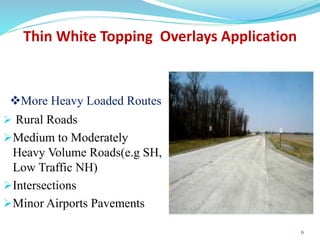

This document discusses different types of white topping pavement overlays, including conventional white topping (CWT), thin white topping (TWT), and ultra-thin white topping (UTWT). CWT is over 200mm thick, TWT is 100-200mm, and UTWT is under 100mm. UTWT requires bonding to the existing asphalt layer by milling 25mm deep. The document outlines the construction process for UTWT/TWT, including milling, cleaning, paving, finishing, curing, and sawing joints. White topping provides benefits like long life, low maintenance, improved safety, and reduction in lighting needs compared to asphalt overlays.