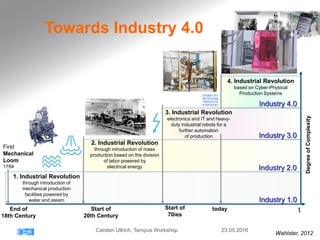

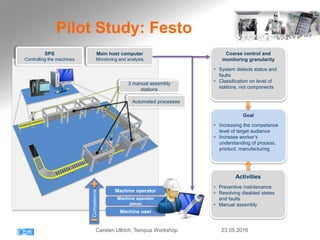

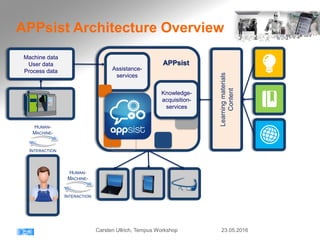

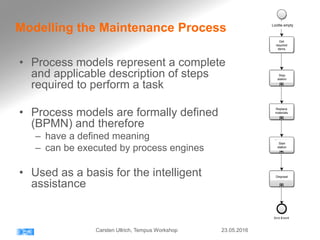

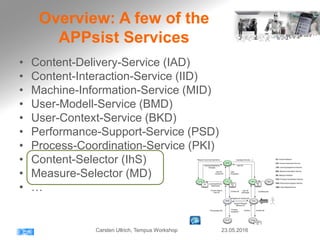

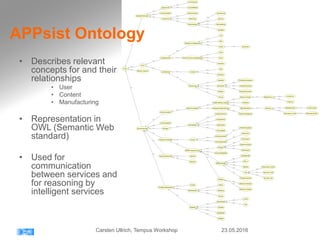

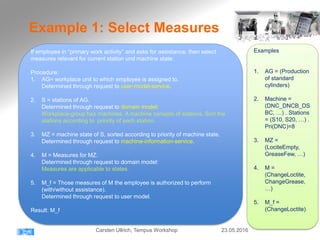

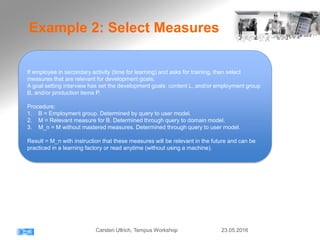

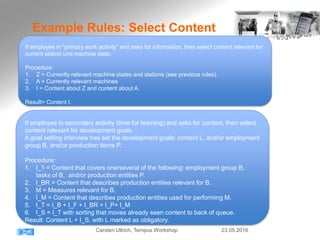

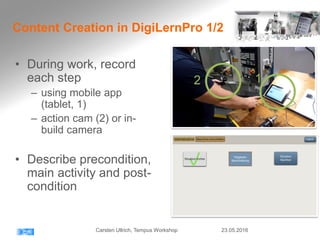

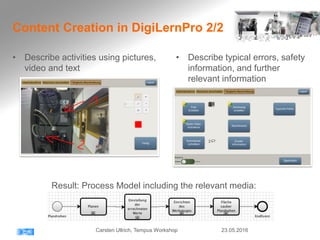

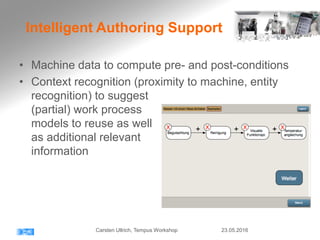

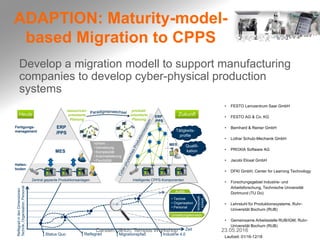

Intelligent adaptive services can provide assistance and facilitate workplace-integrated learning on the shop floor as manufacturing transforms towards Industry 4.0. and cyber-physical production systems. Such services can adapt to individual users and contexts to select appropriate assistance measures, learning content, and processes. They utilize models of the domain, users, and processes to intelligently guide workers. Content can also be created directly in work contexts and shared to support ongoing learning. A maturity model approach can help companies migrate production towards more advanced cyber-physical systems.