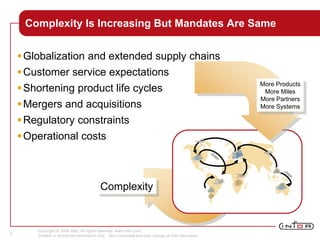

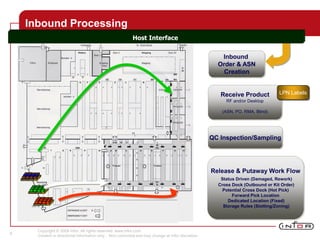

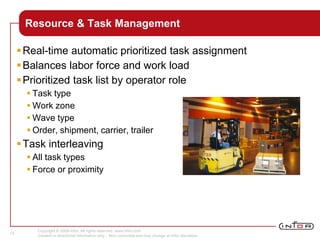

The document discusses the challenges and complexities faced by companies in warehouse management, particularly in the context of globalization, regulatory constraints, and rising customer expectations. It highlights the Infor SCM Warehouse Management 2000 system's capabilities to improve efficiency, reduce costs, and manage warehouse operations effectively through advanced techniques like voice-directed work, inventory management, and labor productivity enhancements. The document also includes customer testimonials and case studies demonstrating successful implementations of the system across various retailers.