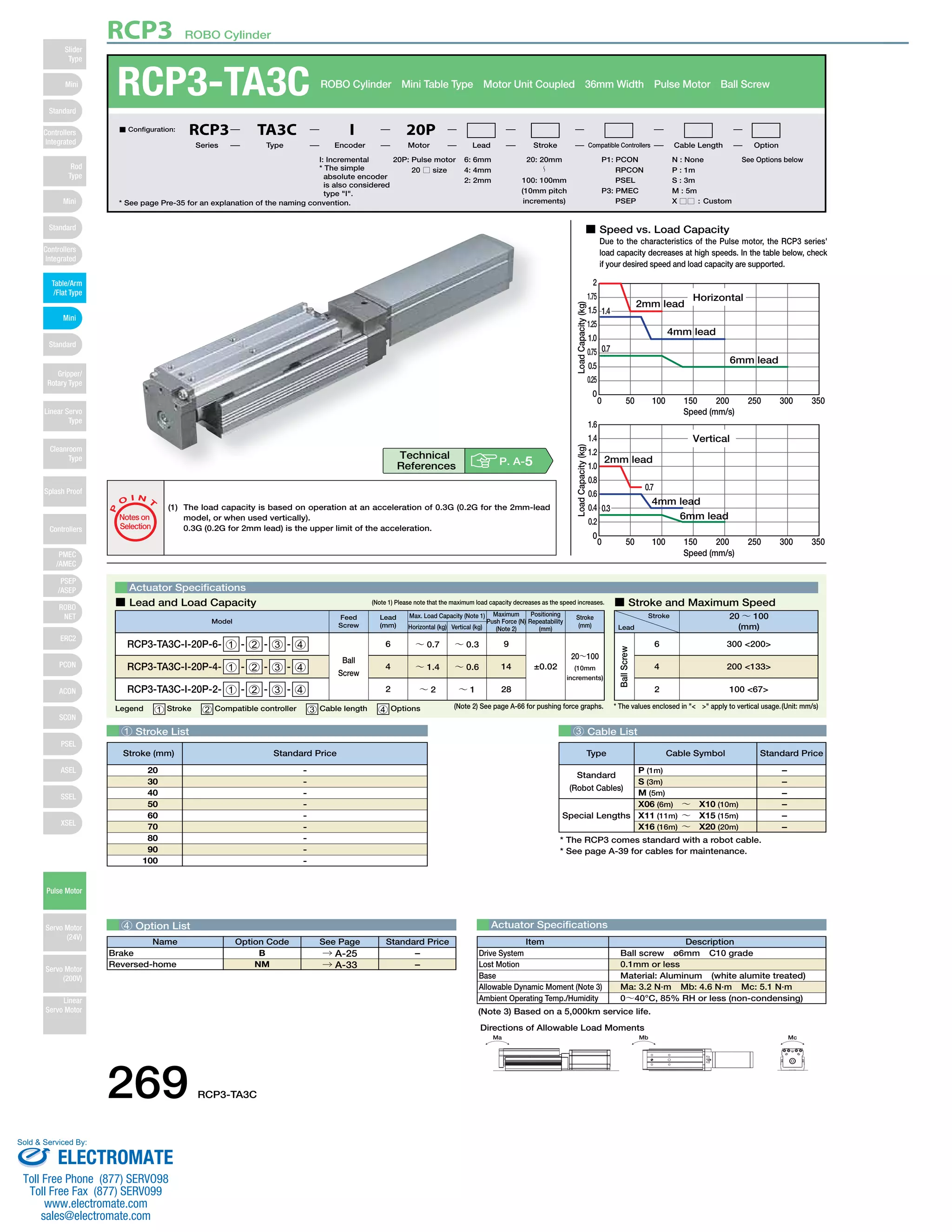

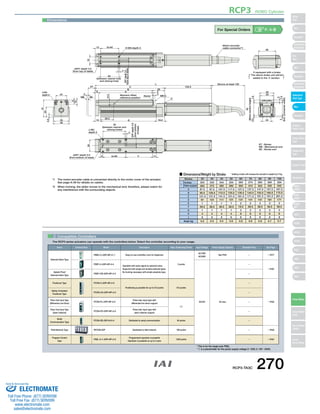

This document provides specifications for the RCP3-TA3C ROBO Cylinder mini table type motor unit. It includes details on the ball screw lead and load capacity, maximum speed and stroke, repeatability, and maximum push force for models with ball screw leads of 2mm, 4mm, and 6mm. Dimensional drawings and weights are provided for no brake and brake-equipped models across strokes of 20mm to 100mm. Compatible controllers include solenoid valve types, positioner types, pulse train input types, serial communication types, and program control types.