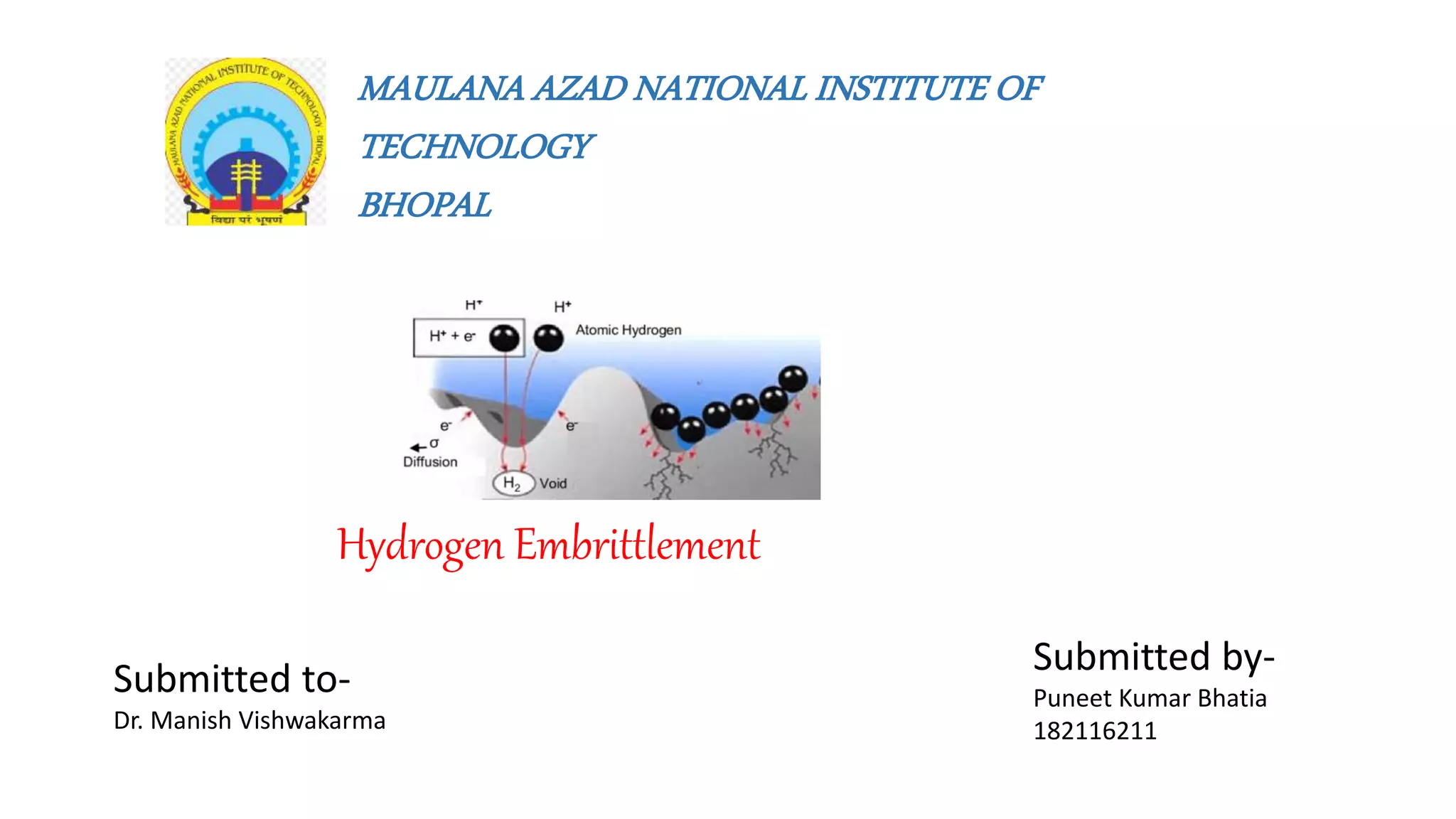

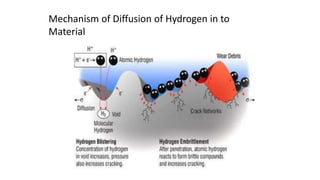

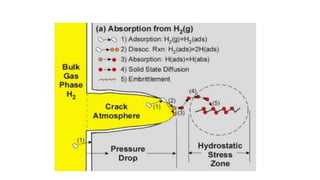

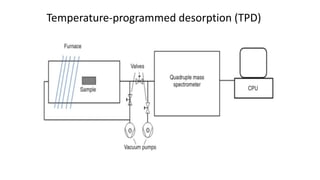

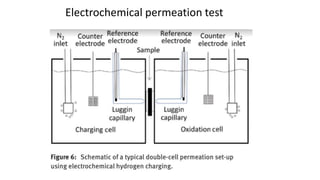

The document discusses hydrogen embrittlement, which is when metals like titanium and vanadium become brittle due to hydrogen diffusion. Hydrogen is introduced through processes like welding, corrosion, and melting. There are three proposed mechanisms for embrittlement: hydrogen-enhanced de-cohesion causes reduced bonding strength; hydrogen-enhanced local plasticity enhances localized plastic deformation; and adsorption-induced dislocation emission facilitates dislocation movement near cracks. Tests like linearly increasing stress tests, temperature-programmed desorption, and electrochemical permeation help evaluate embrittlement.