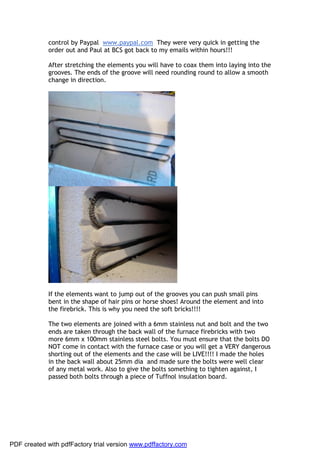

The document provides instructions for building a home heat treatment furnace. It describes the materials needed such as firebricks and metal sheeting. It details constructing the furnace body and casing, cutting grooves for the heating elements, and installing the elements and wiring. Safety warnings are given regarding working with high voltages and temperatures.