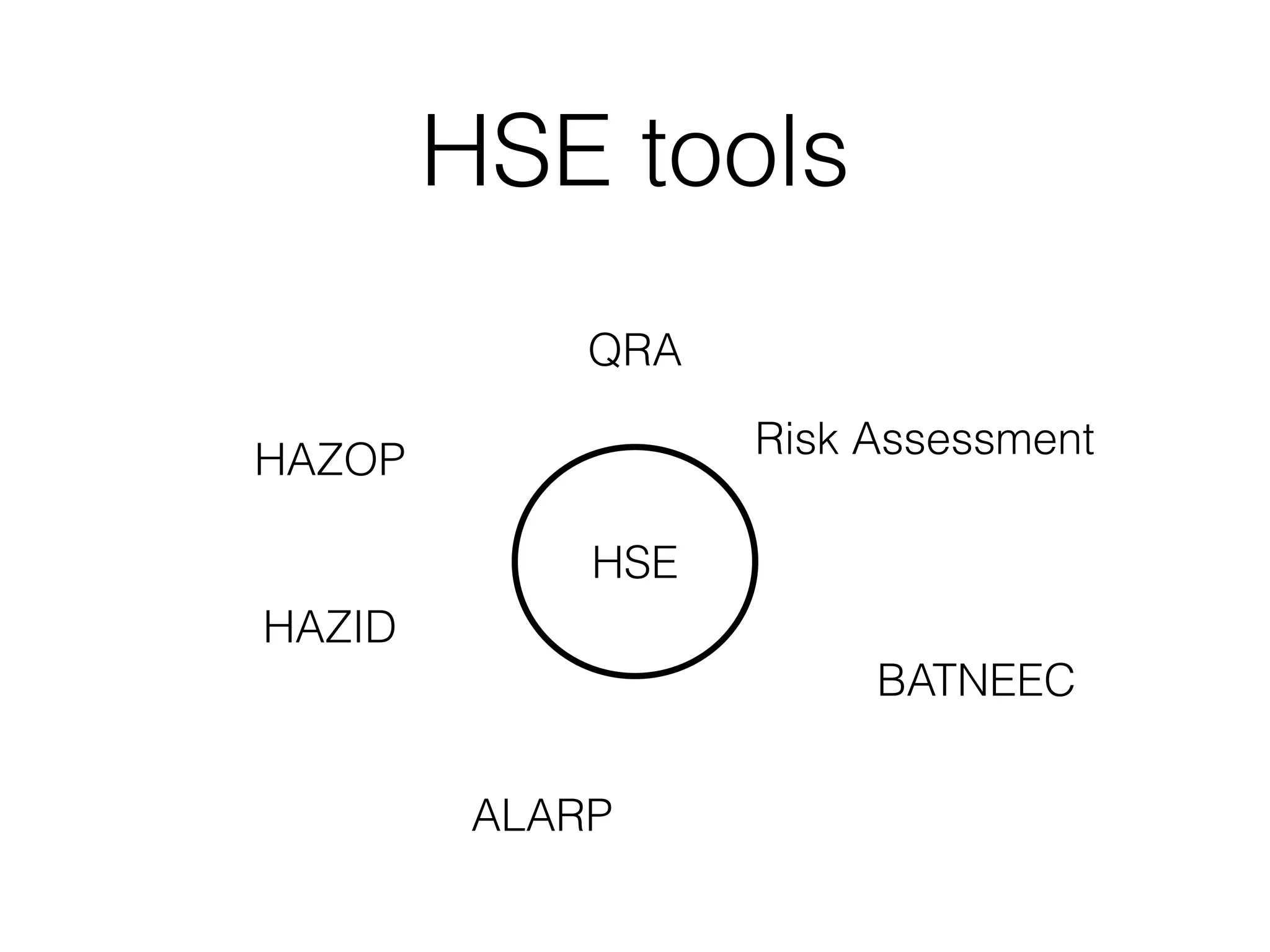

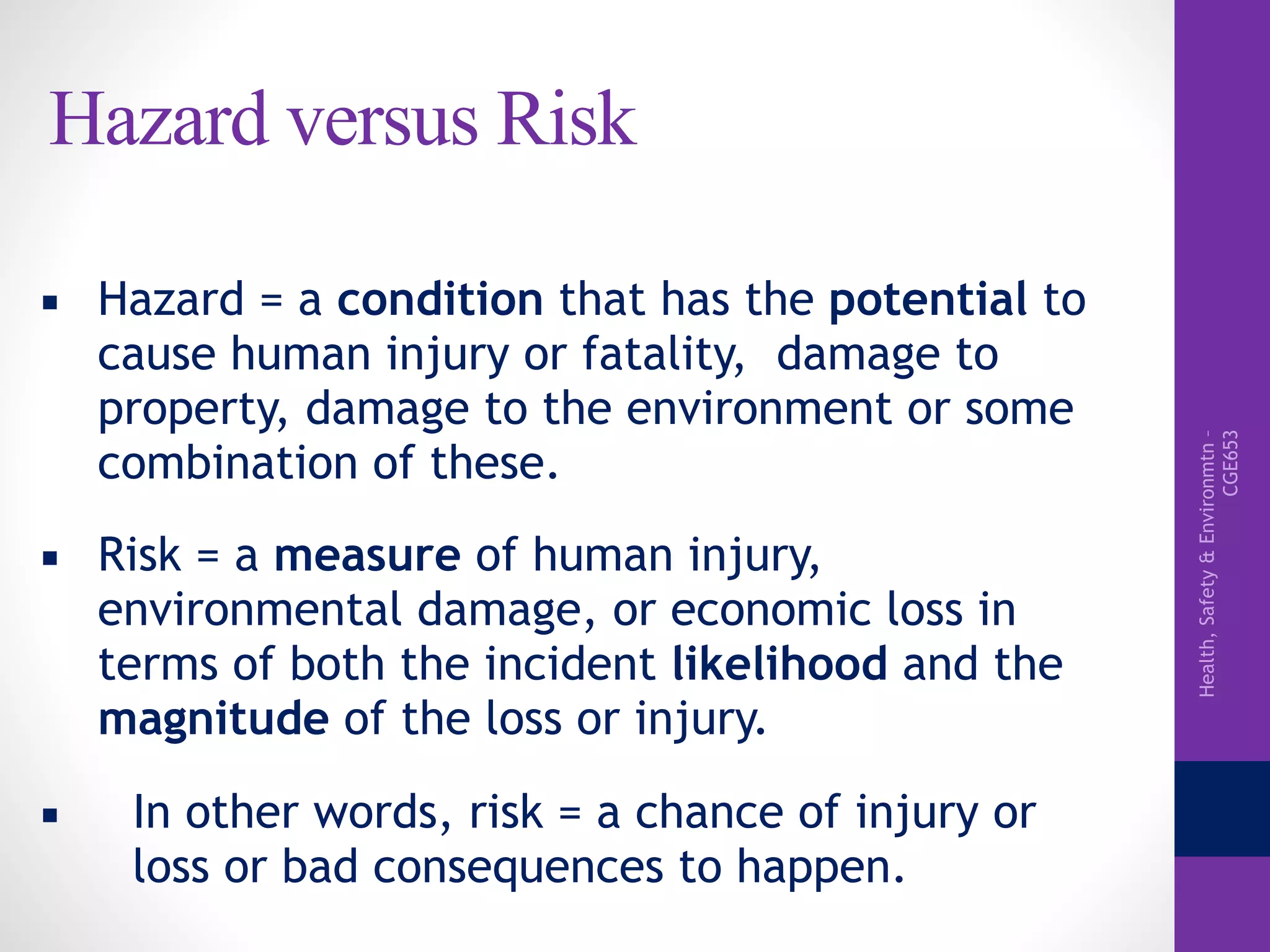

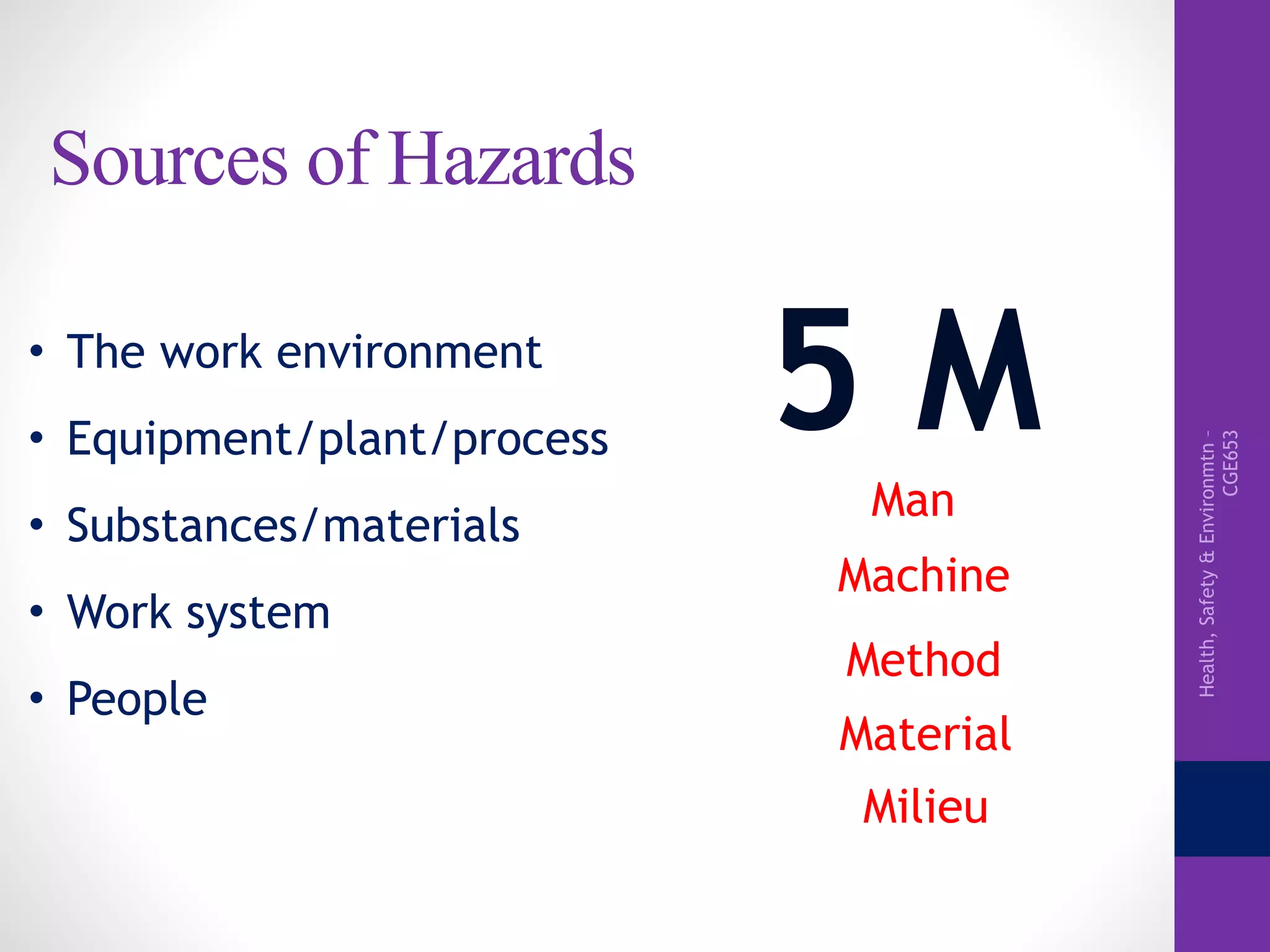

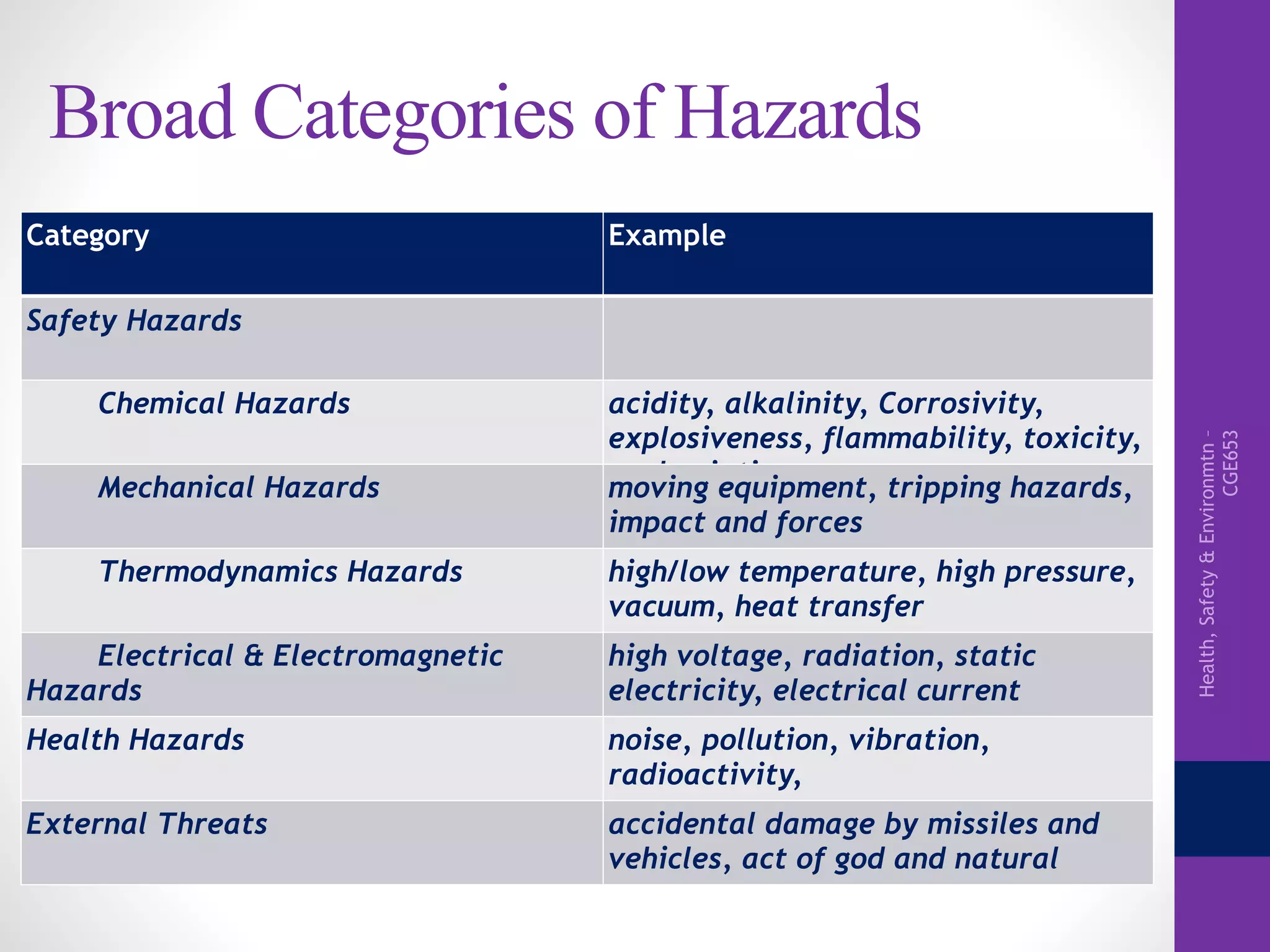

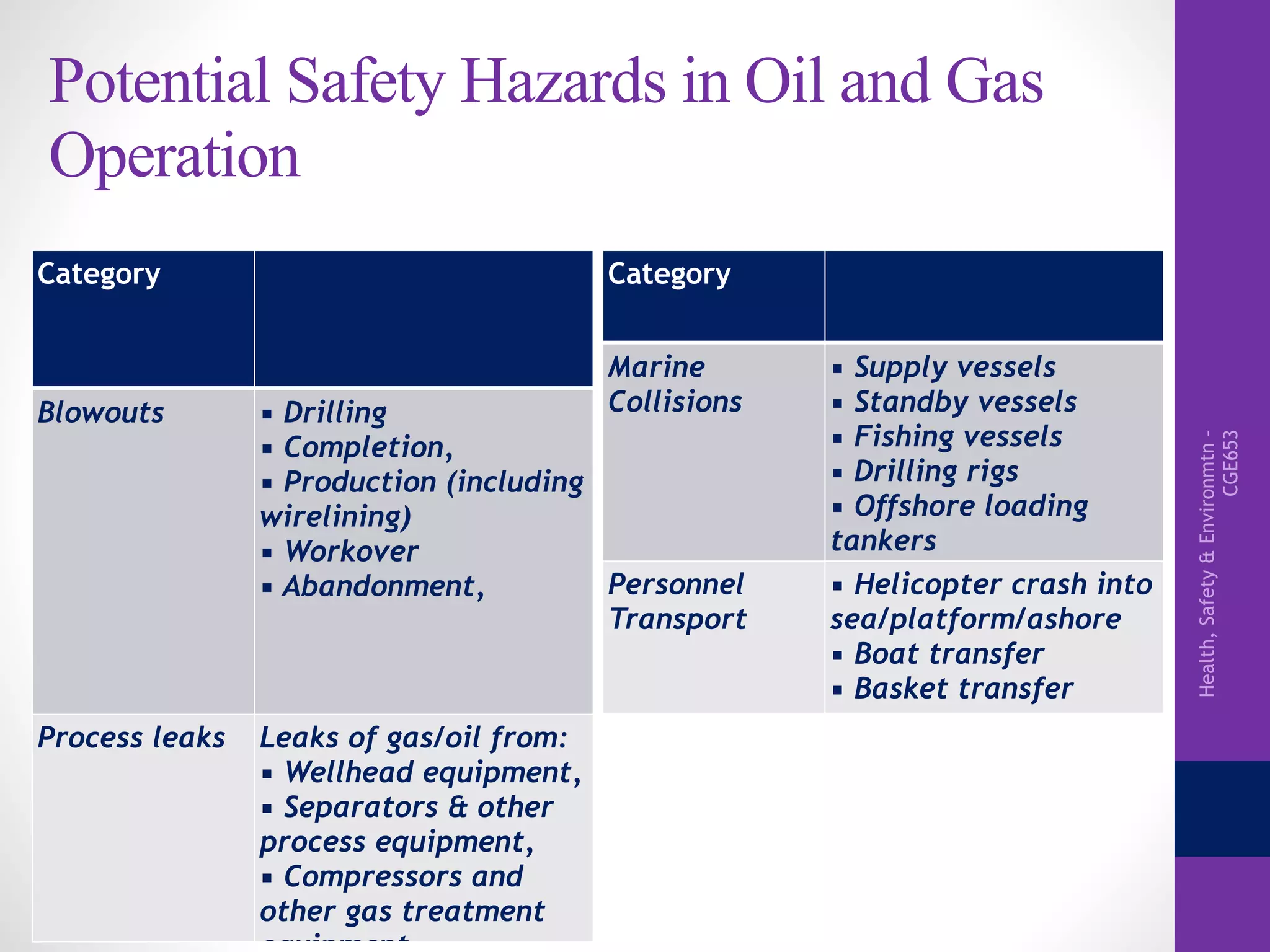

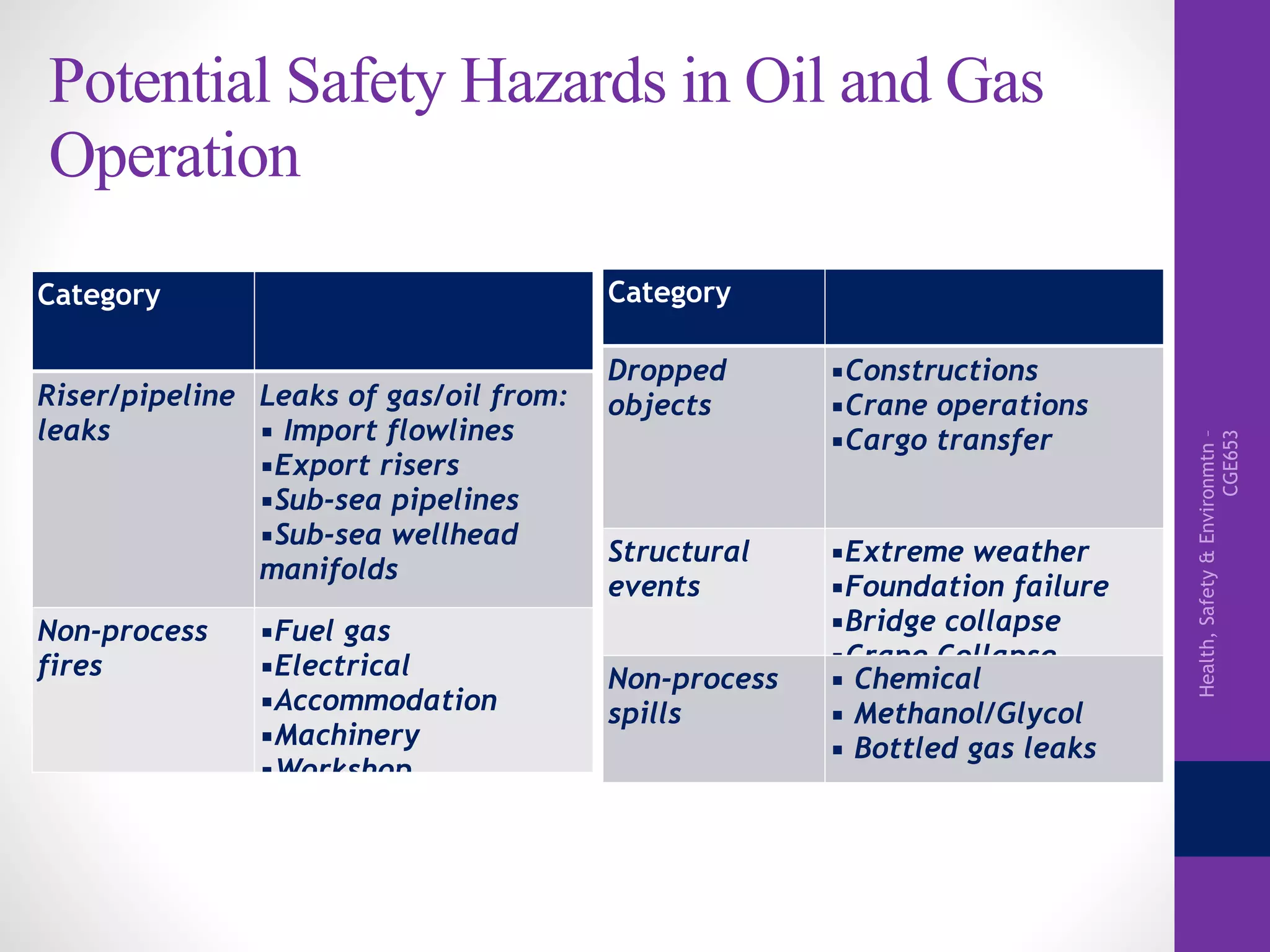

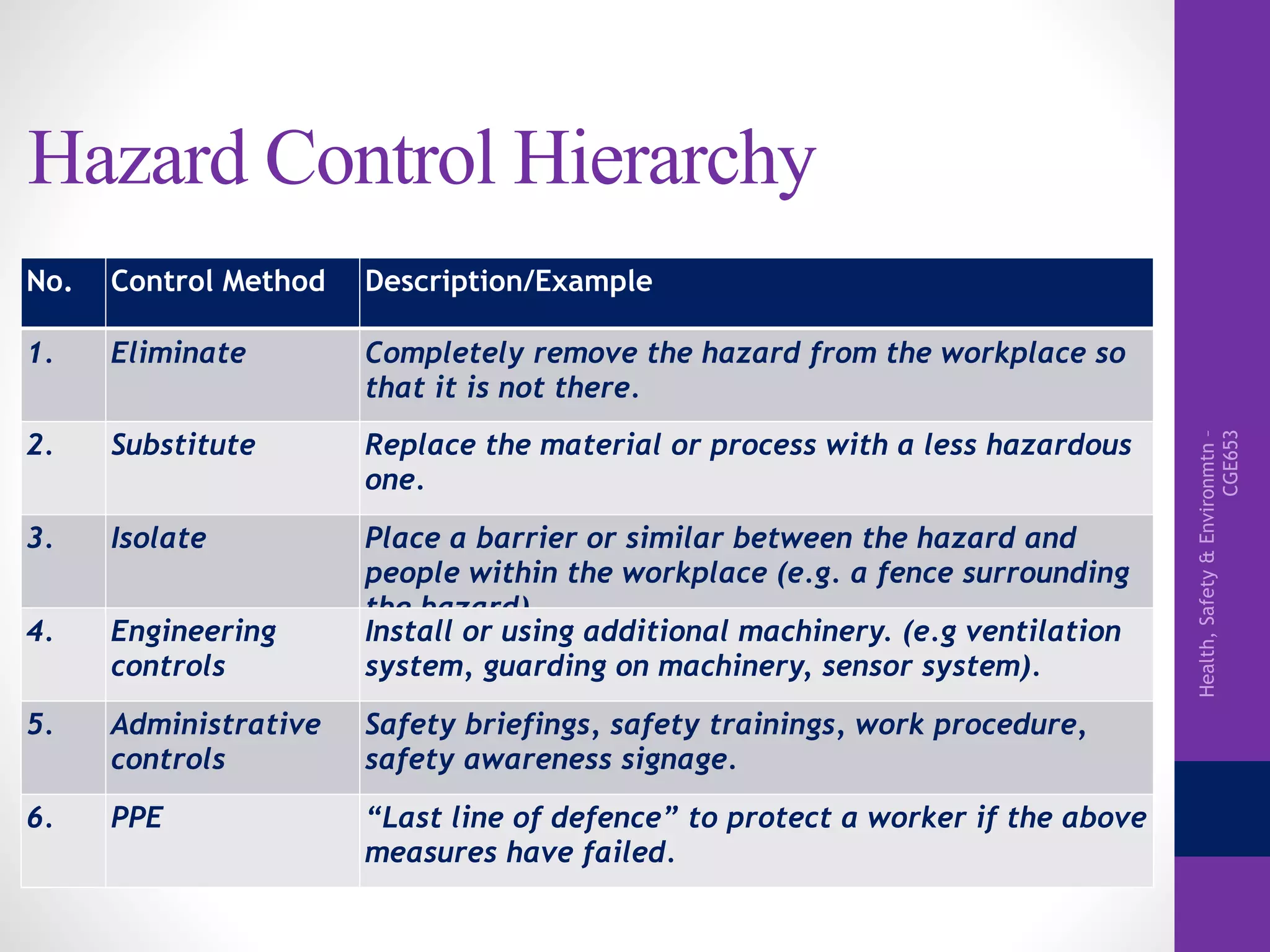

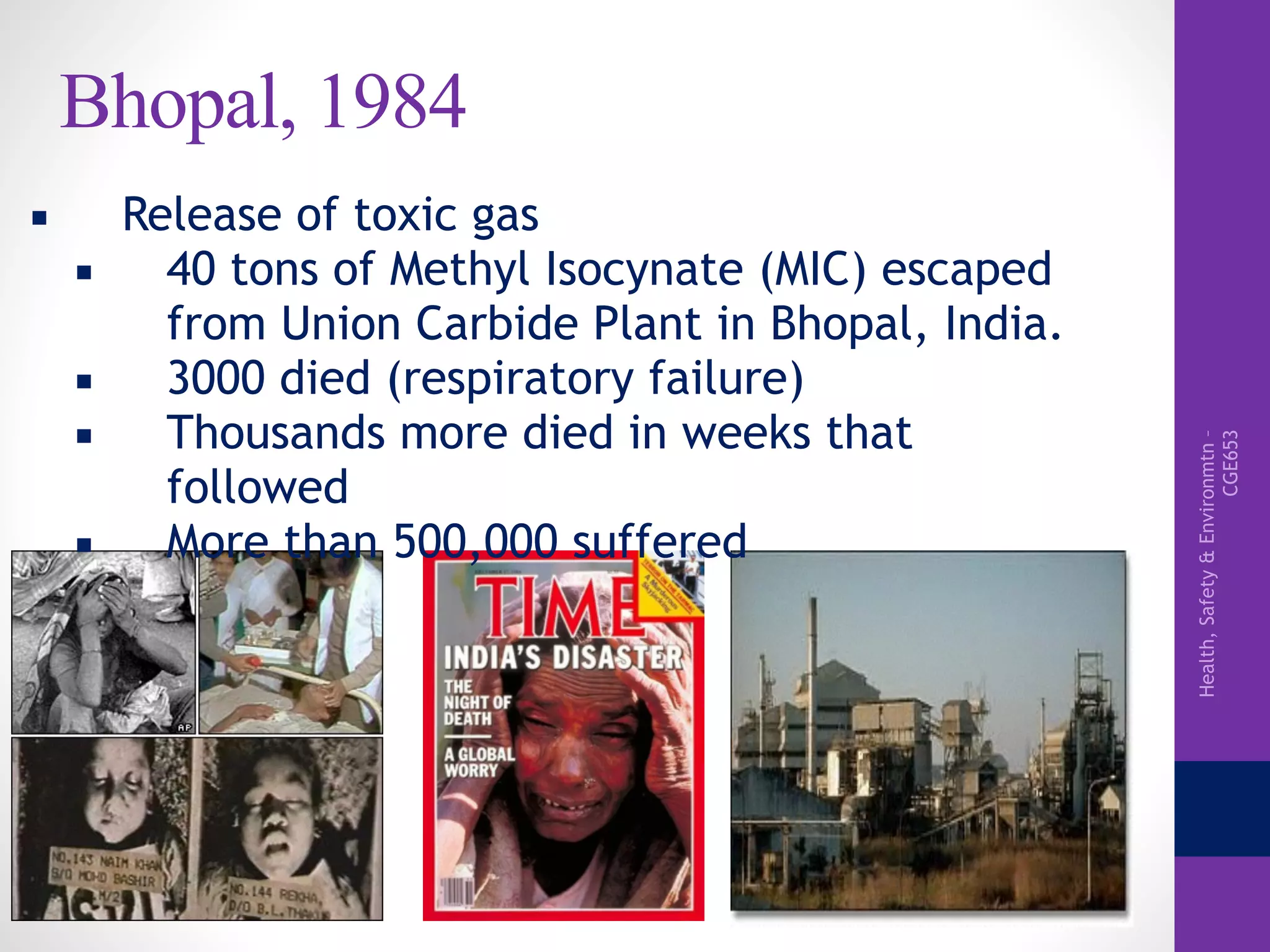

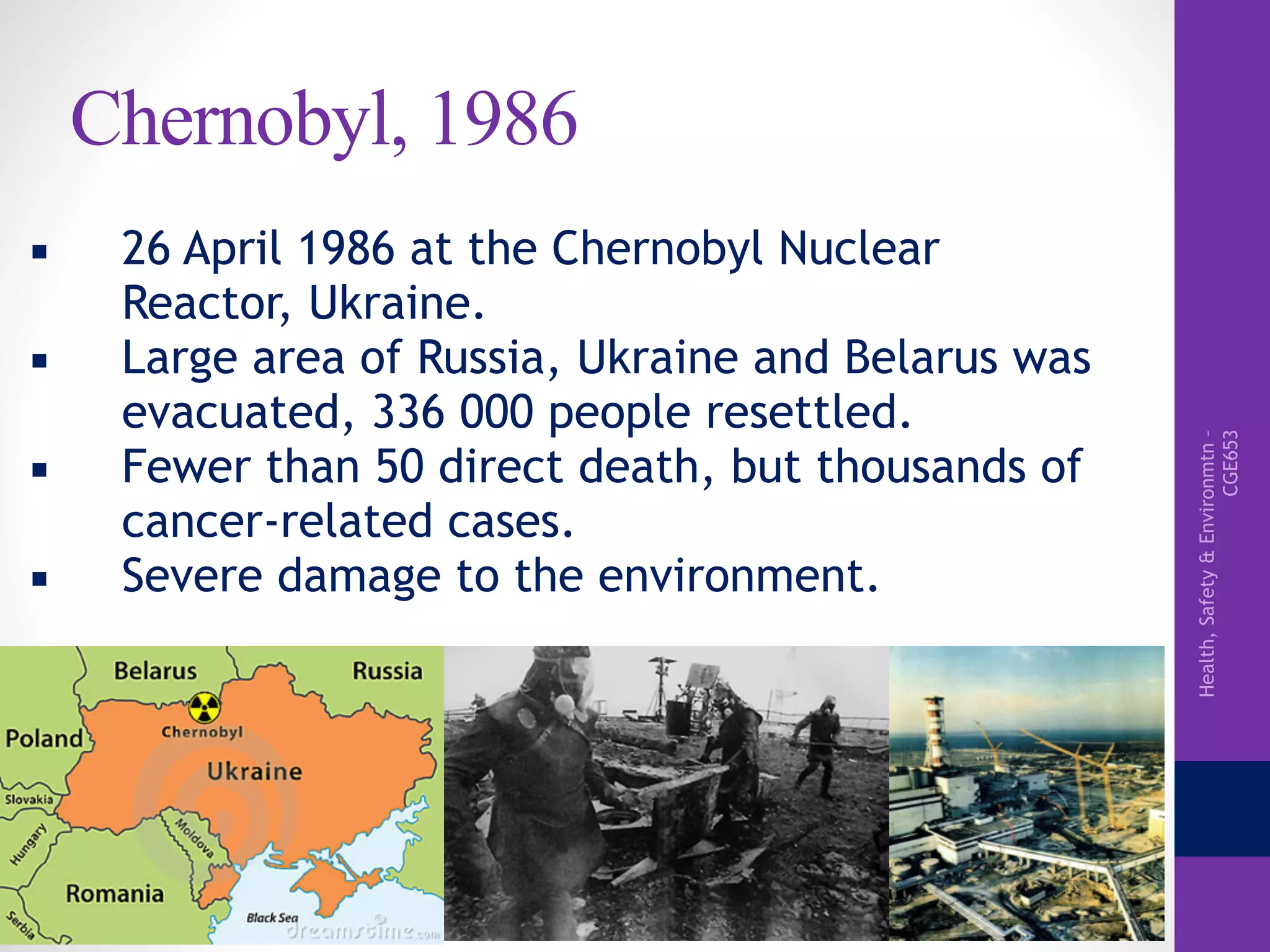

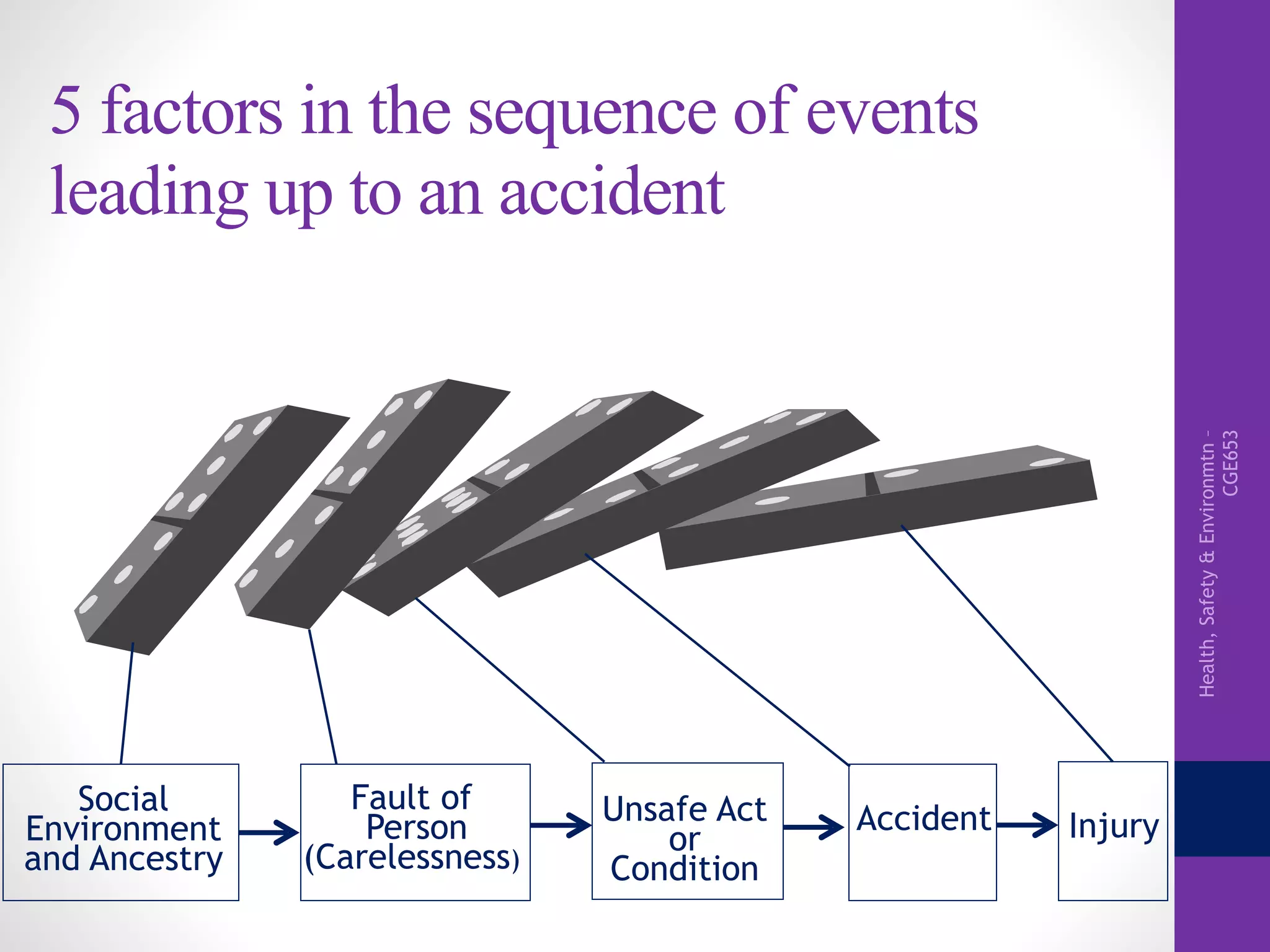

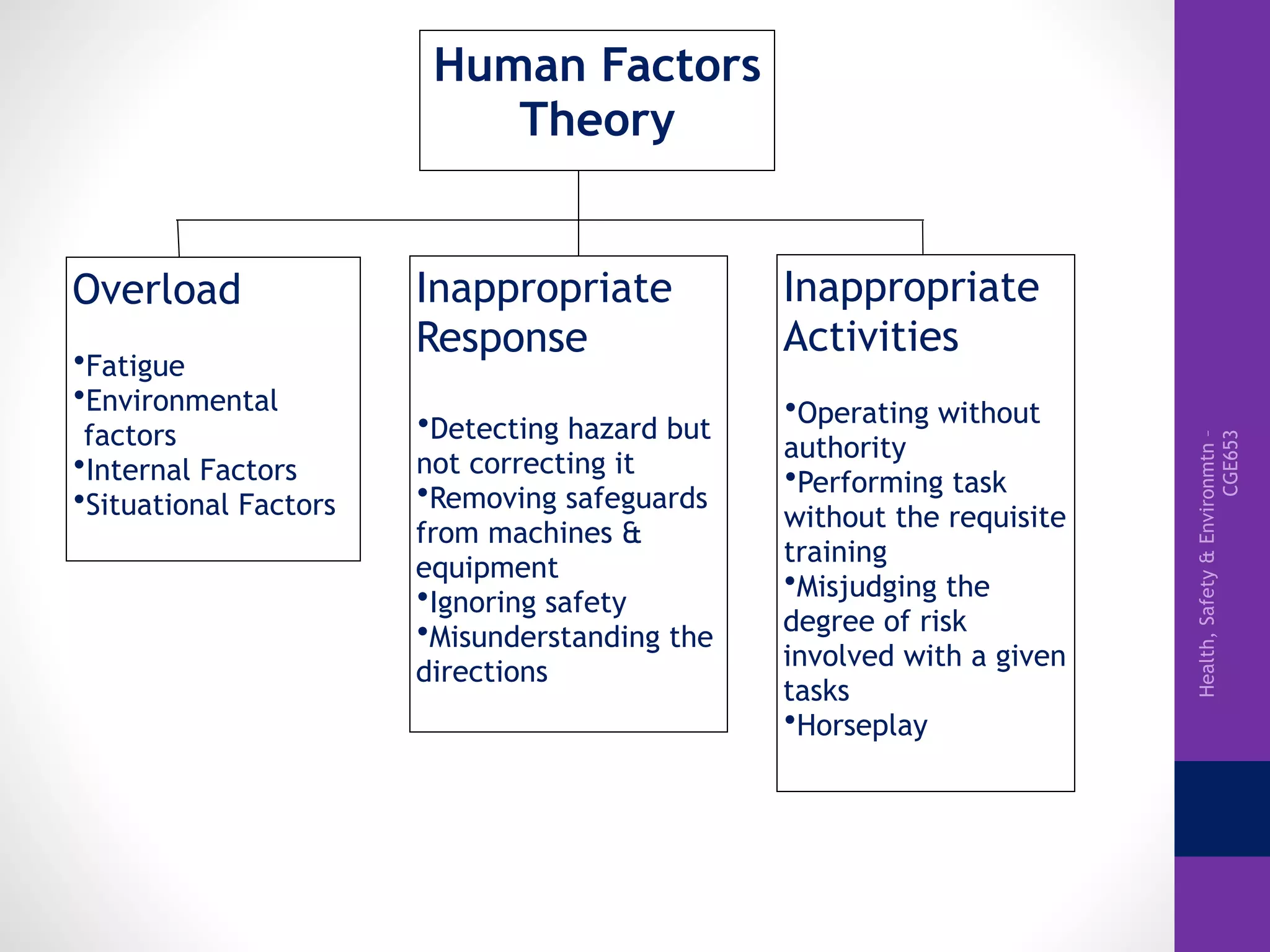

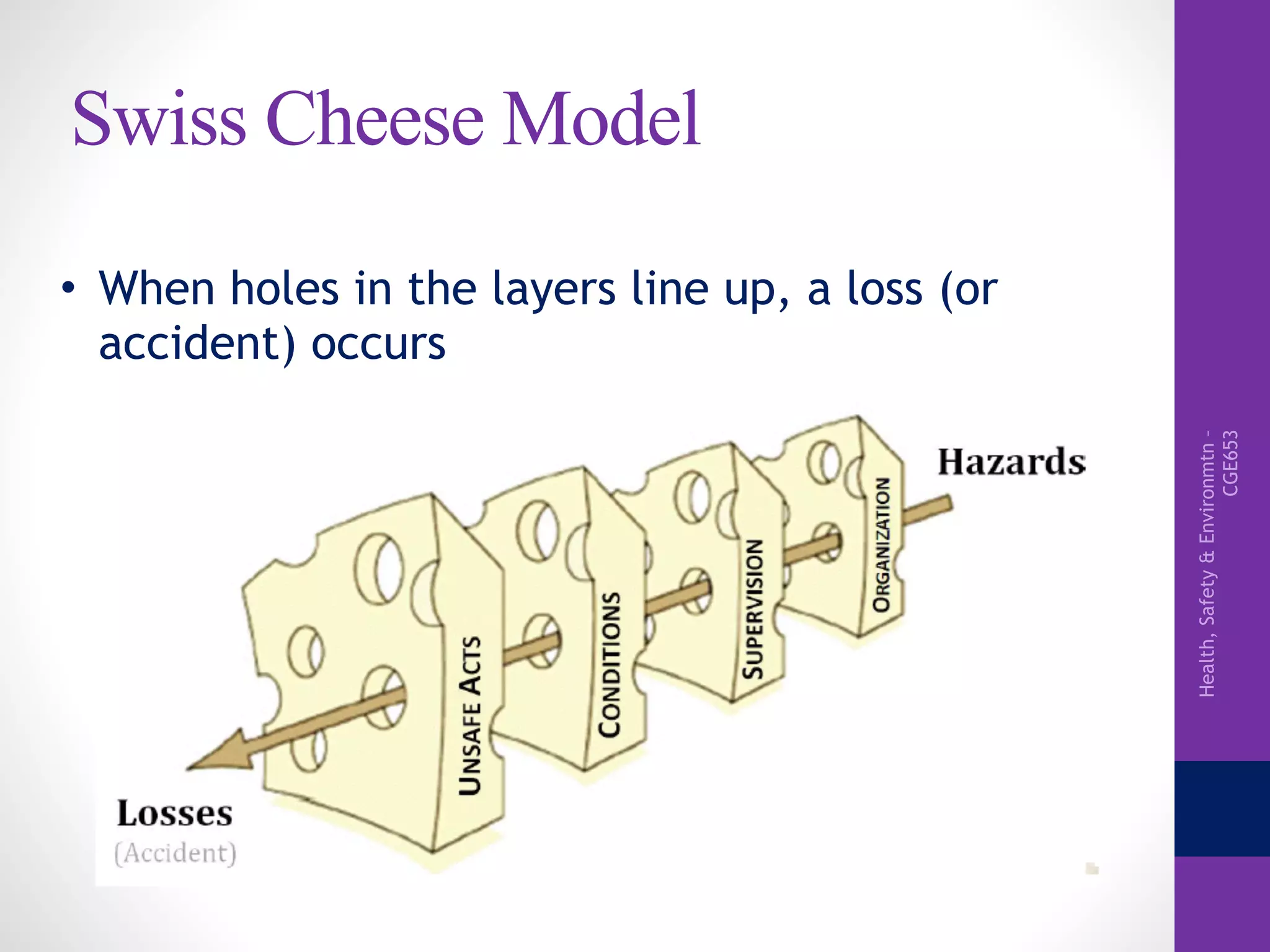

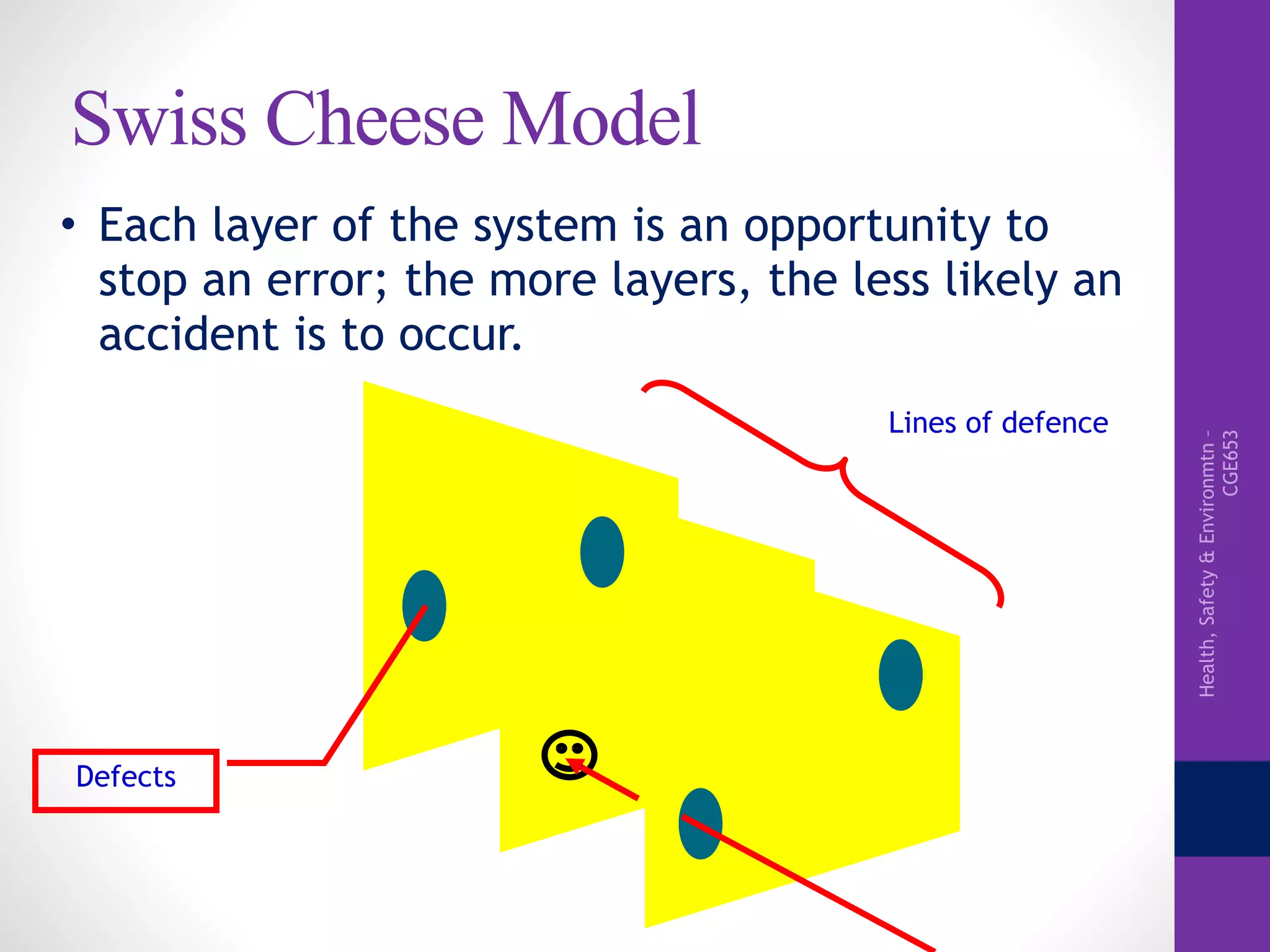

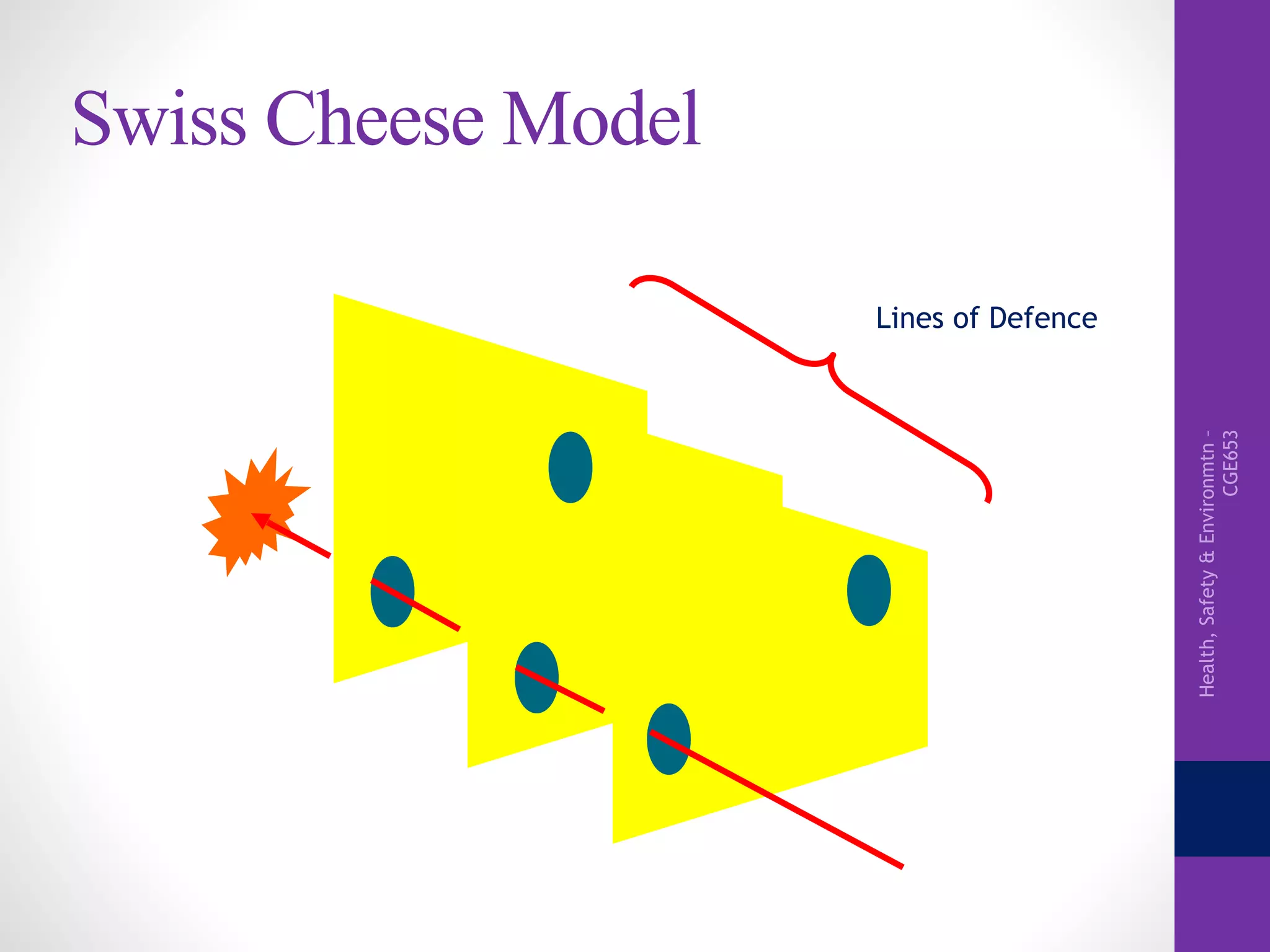

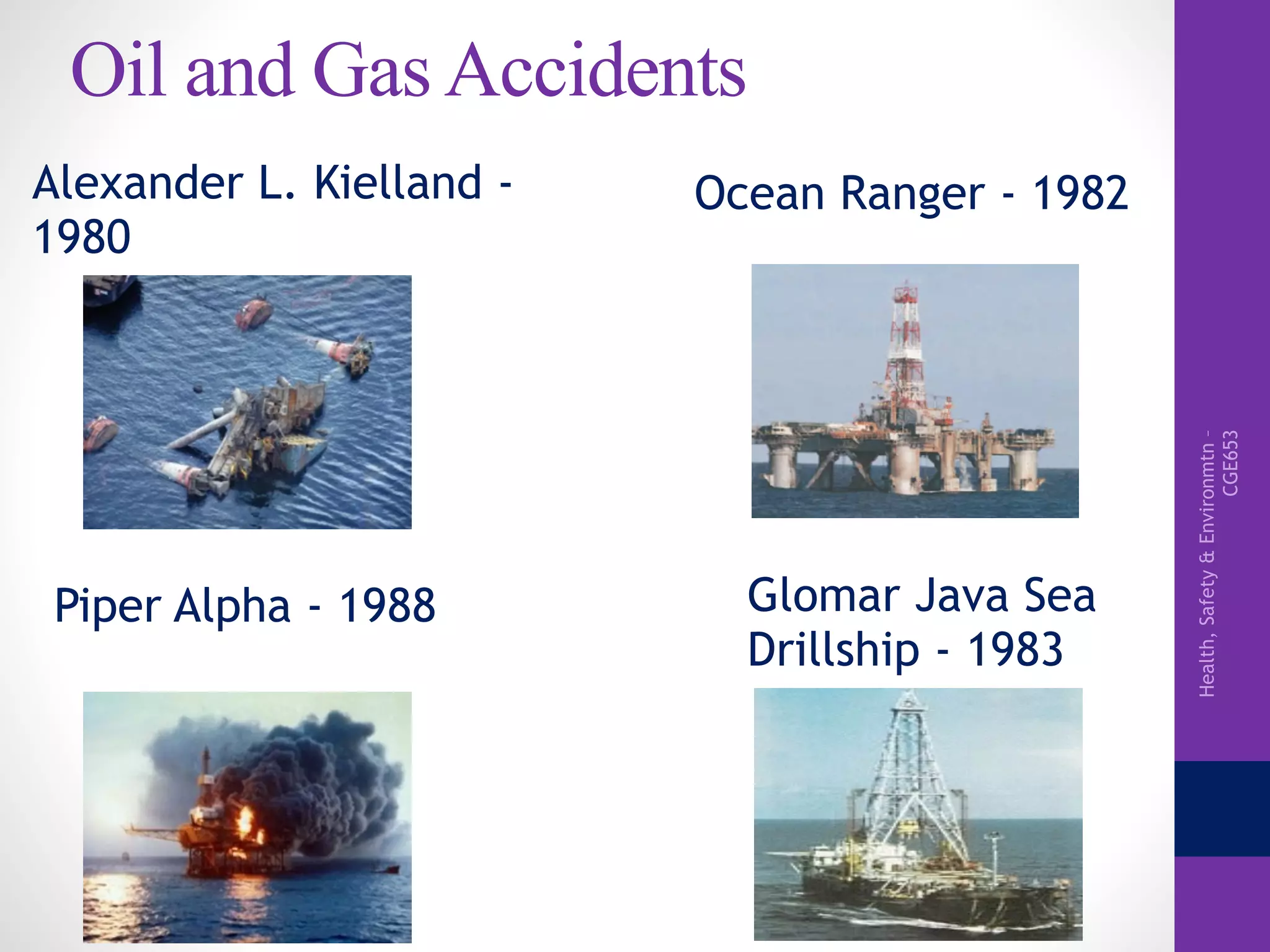

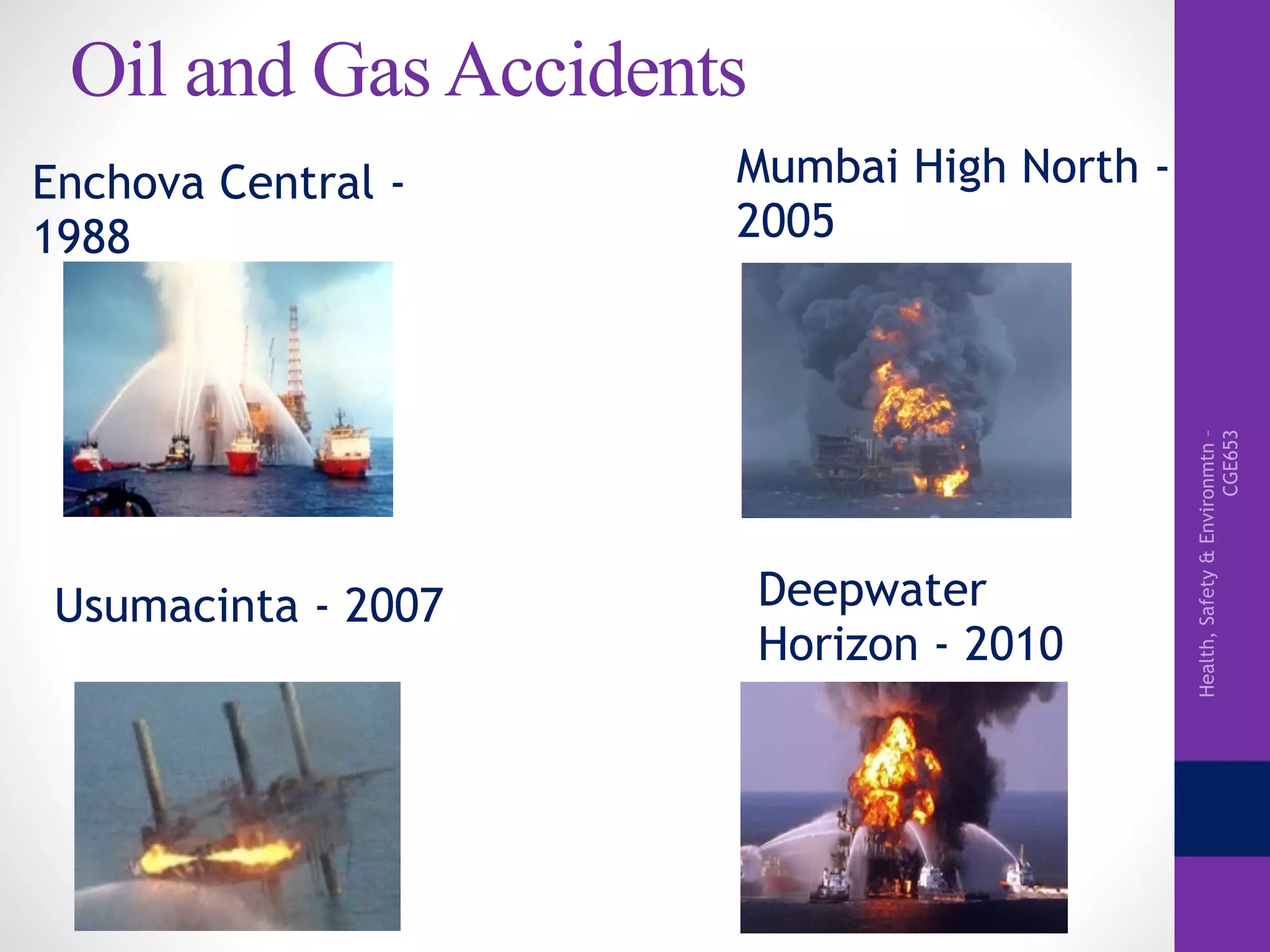

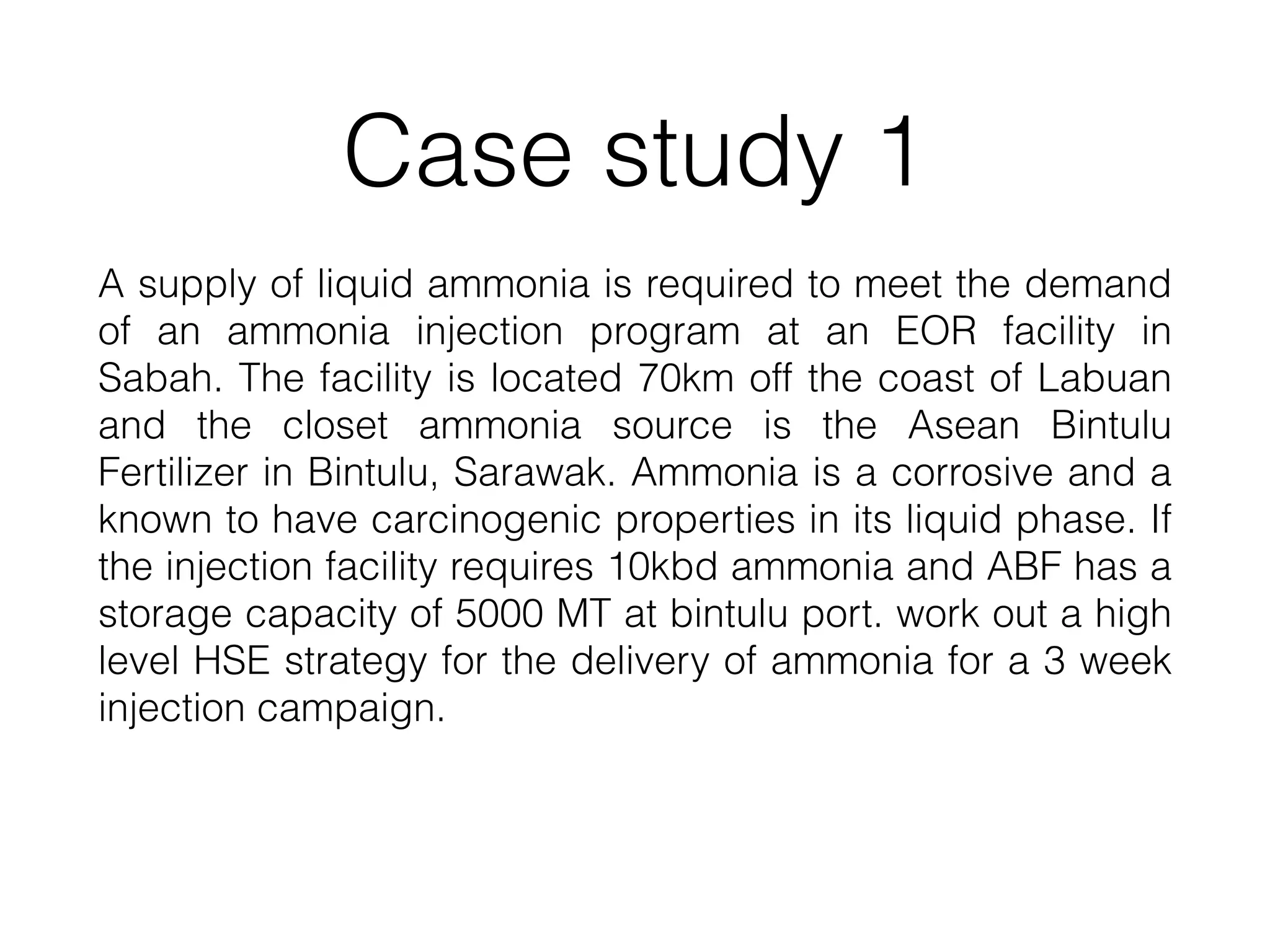

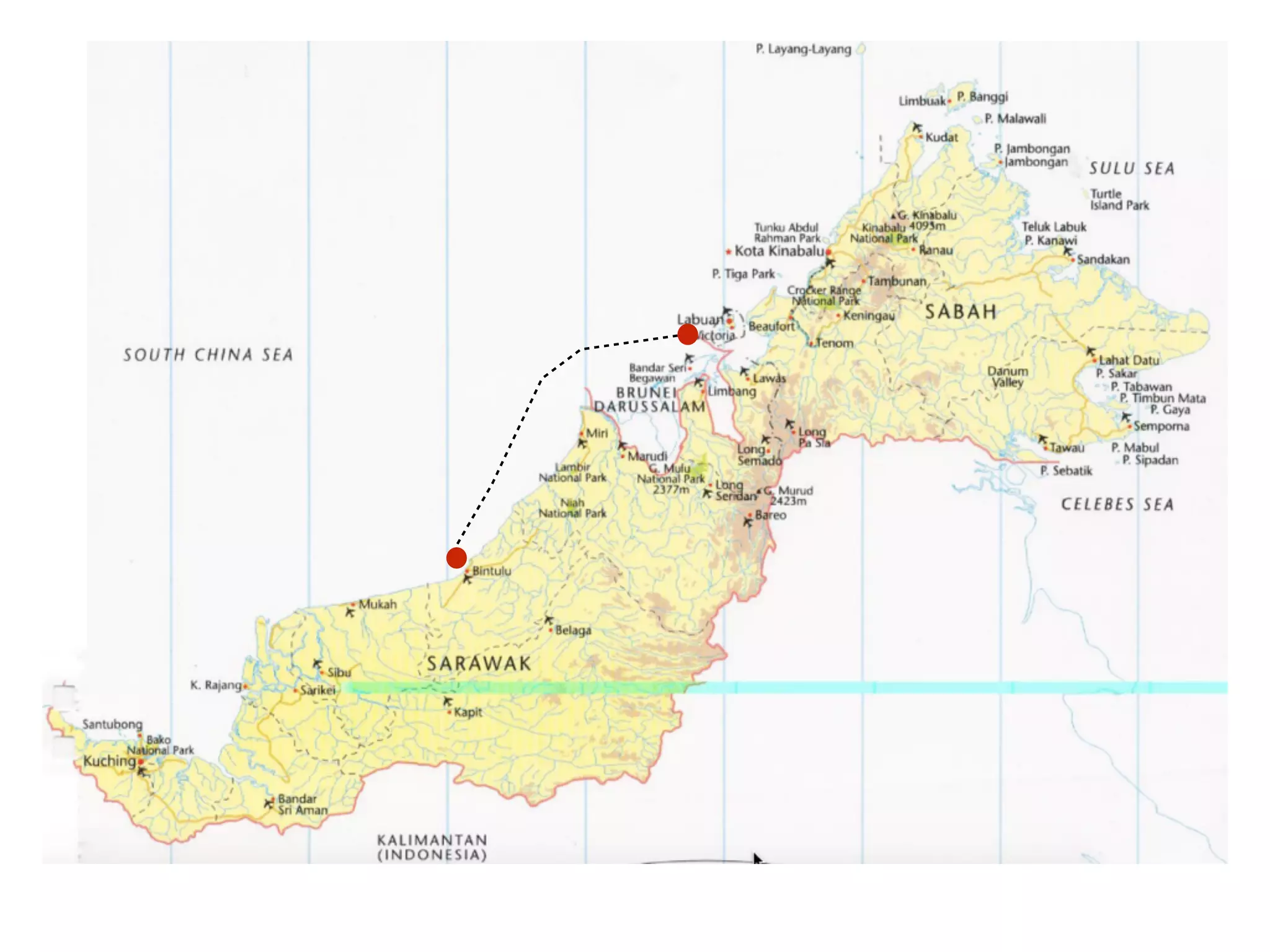

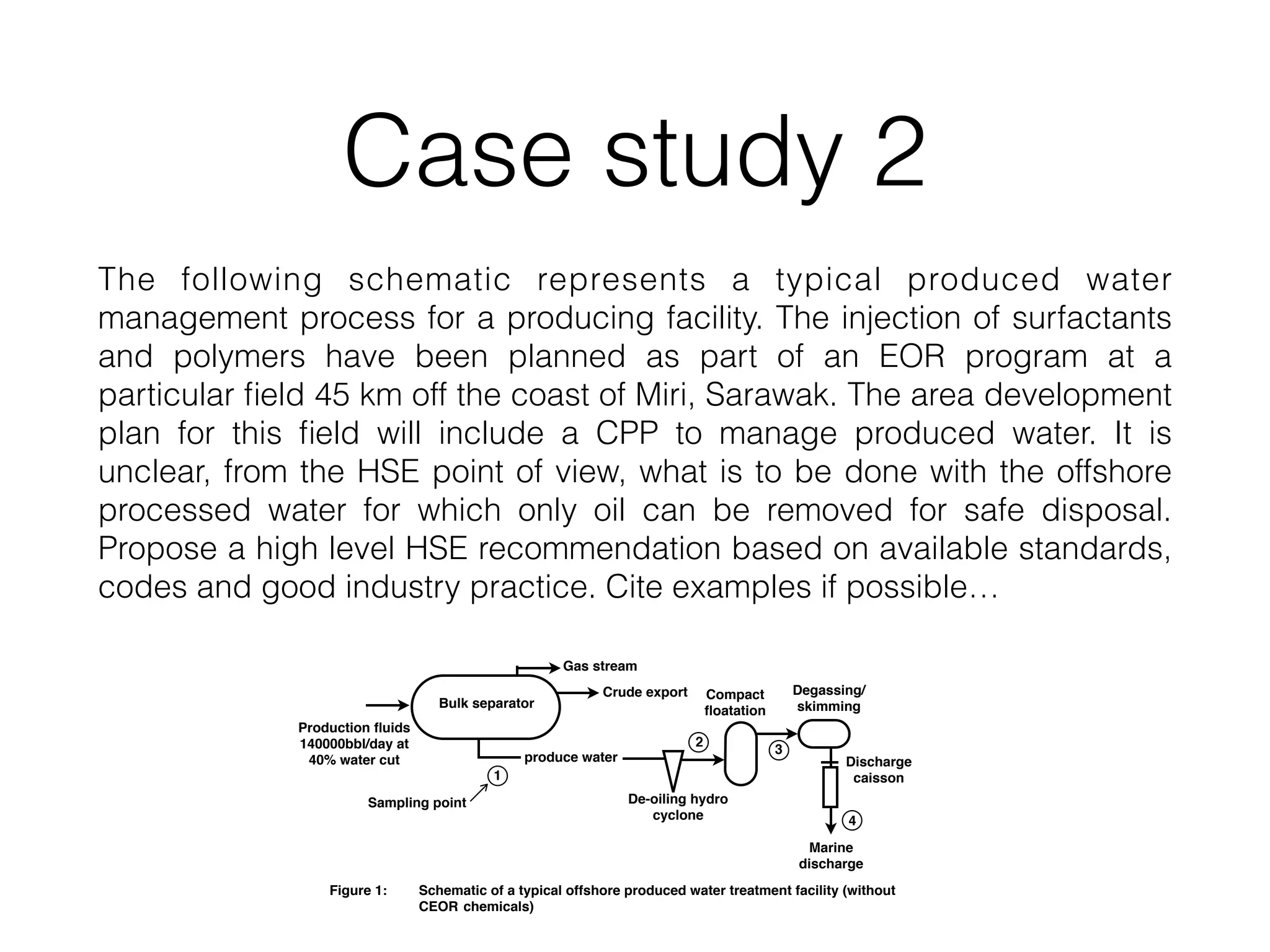

This document discusses health, safety and the environment (HSE) in engineering. It defines key HSE terms and outlines various hazards, risks, and approaches to hazard control. Major industrial accidents from history are reviewed to demonstrate the importance of safety. The costs of accidents, both direct and indirect, are discussed. The document emphasizes that safety is good for business and outlines engineers' responsibilities regarding HSE.