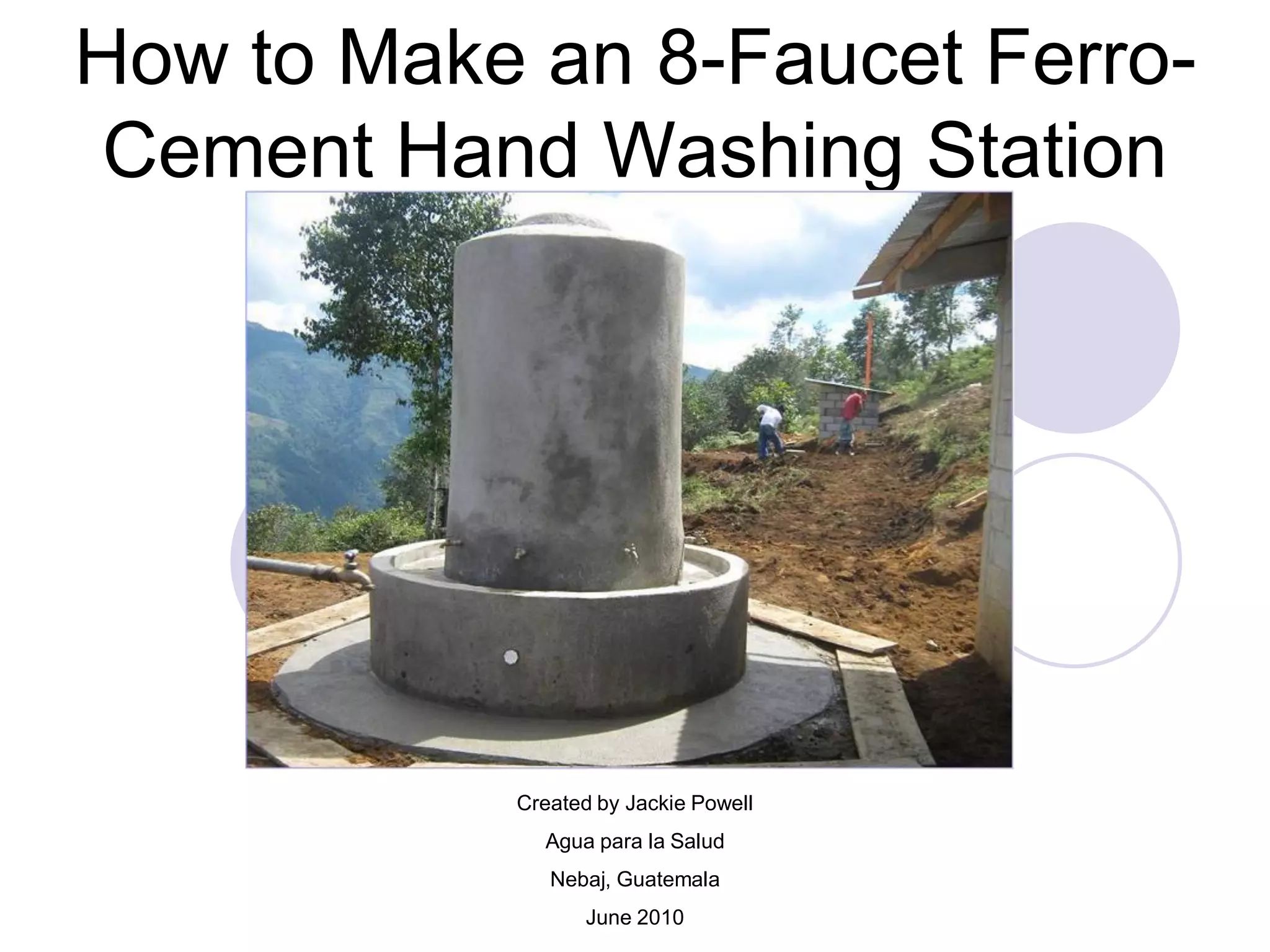

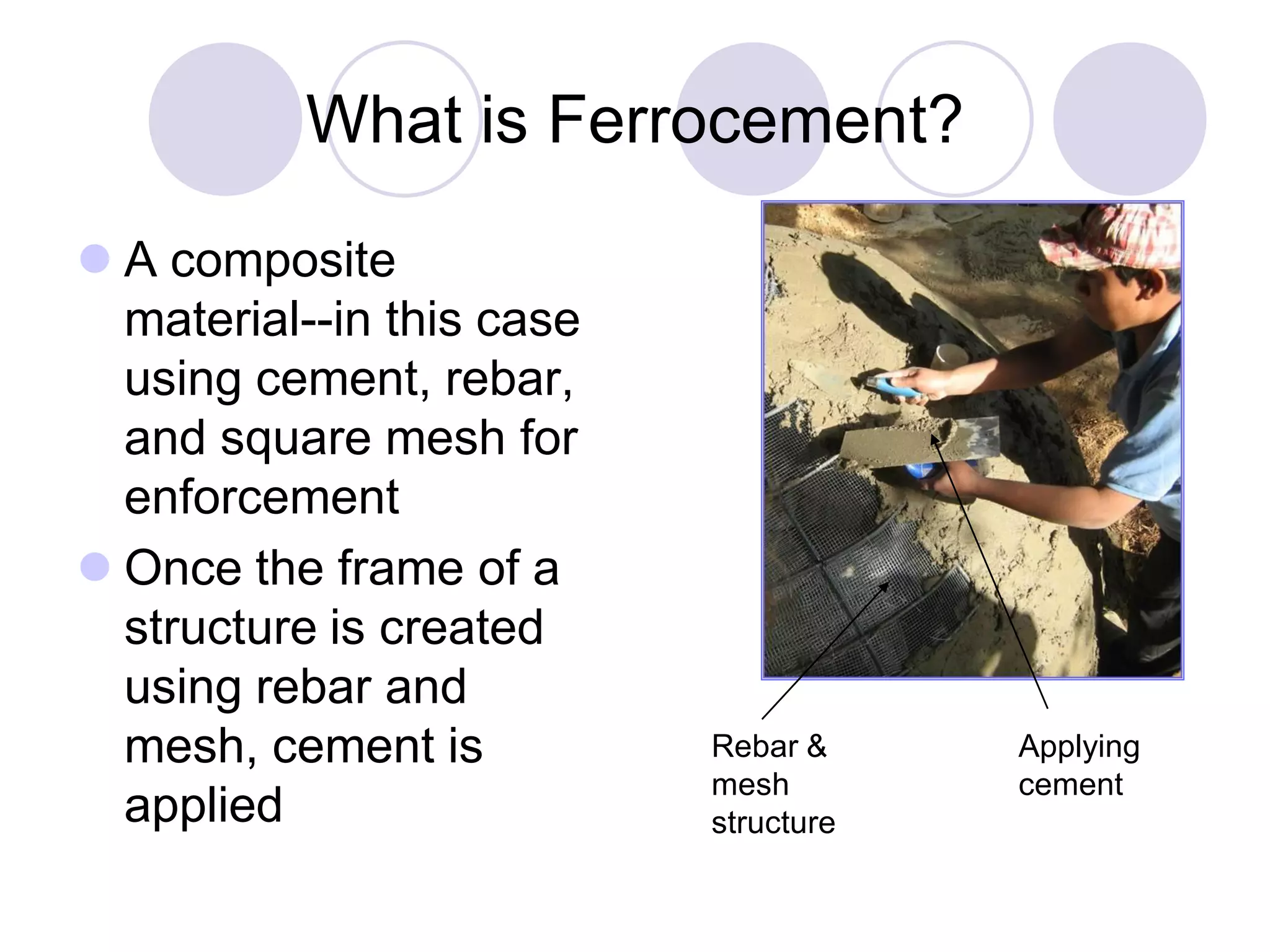

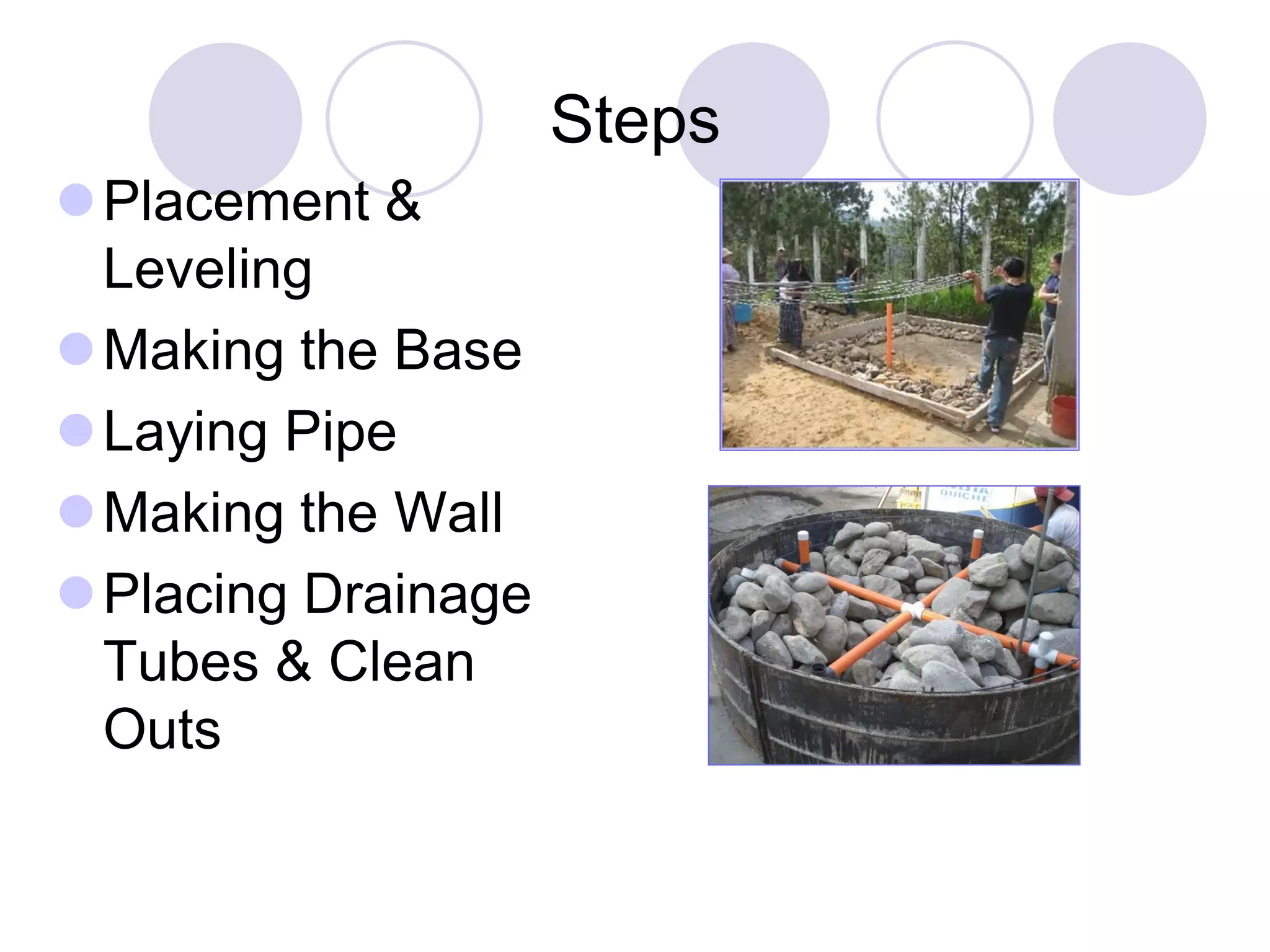

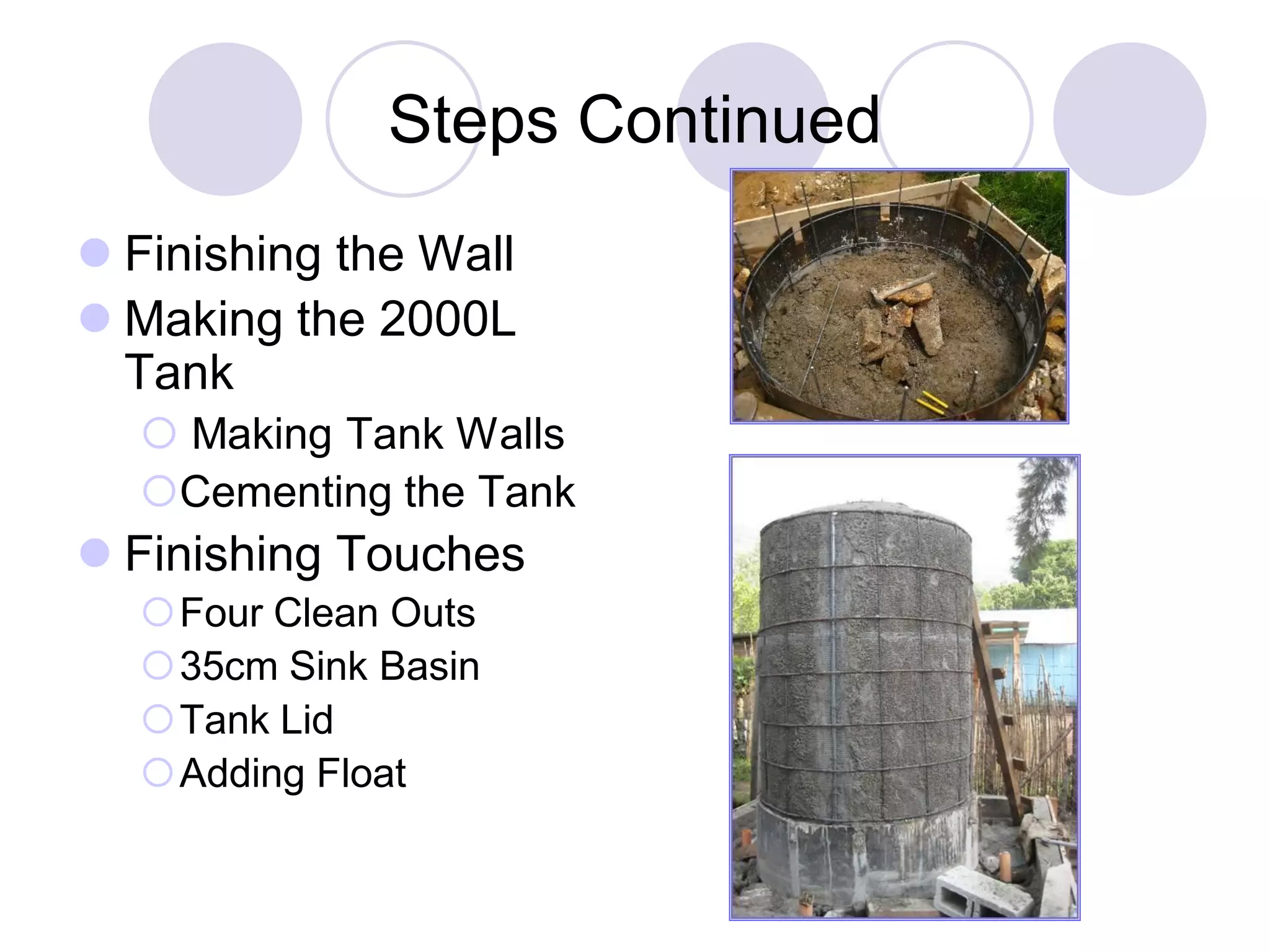

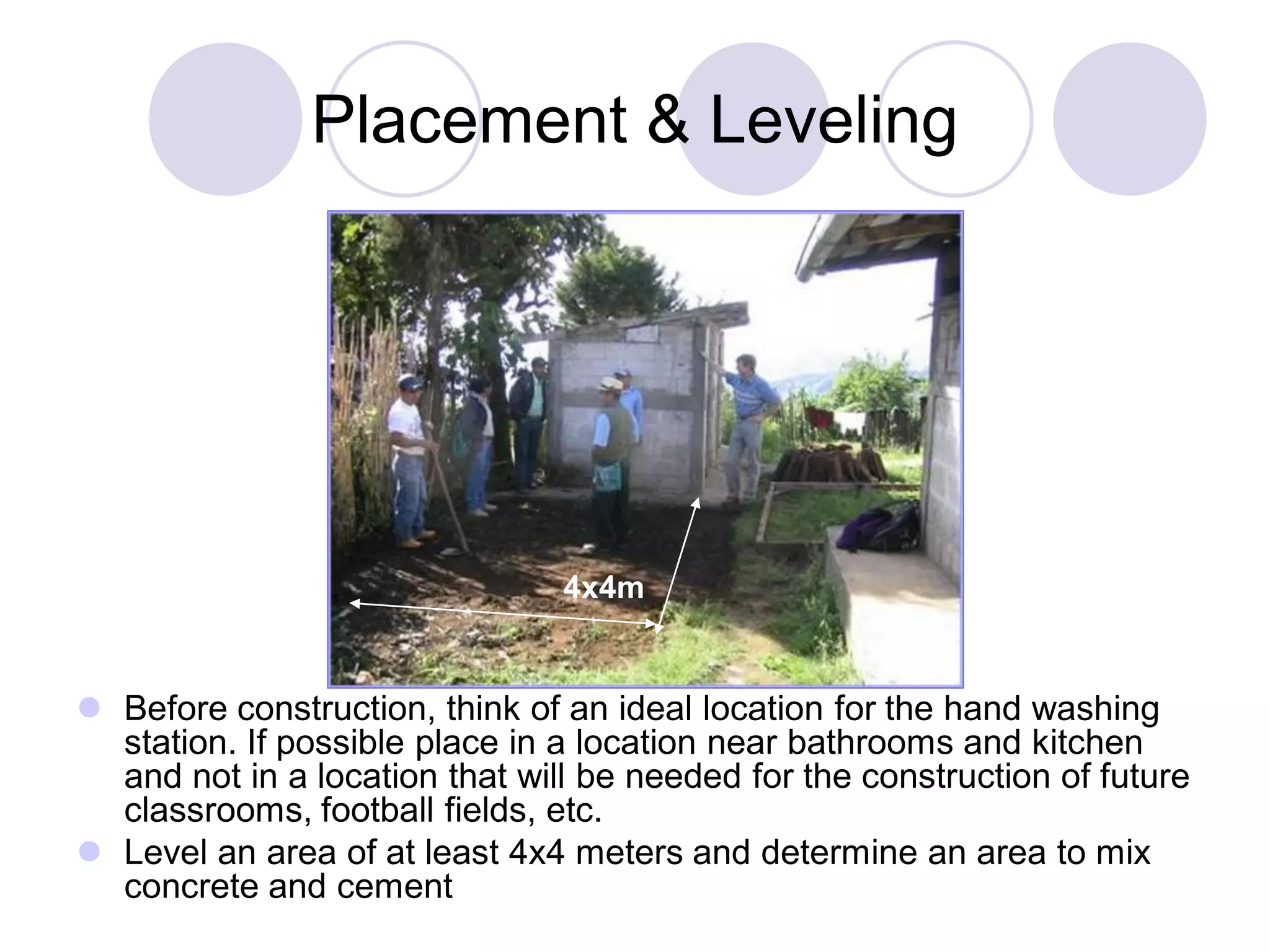

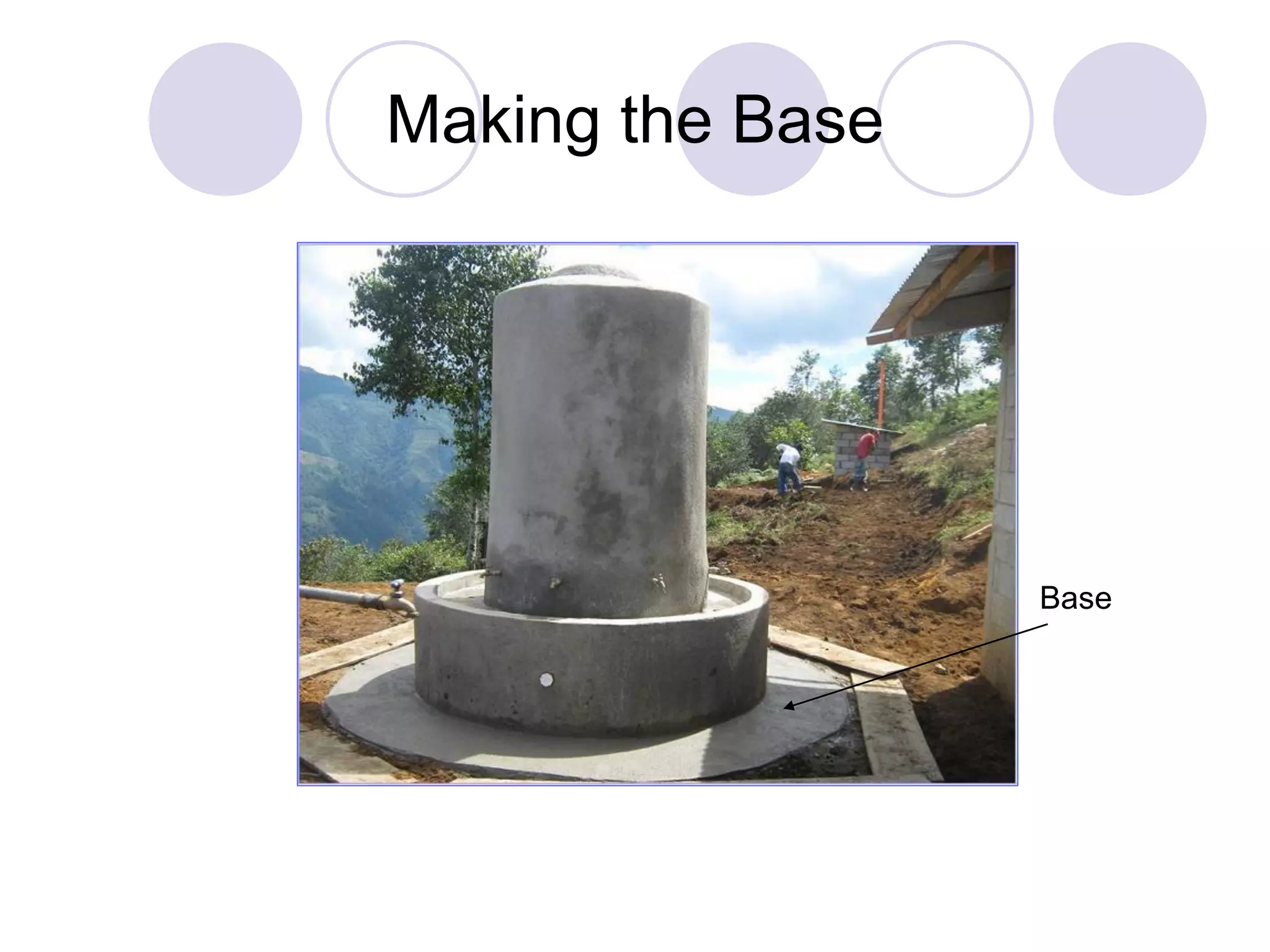

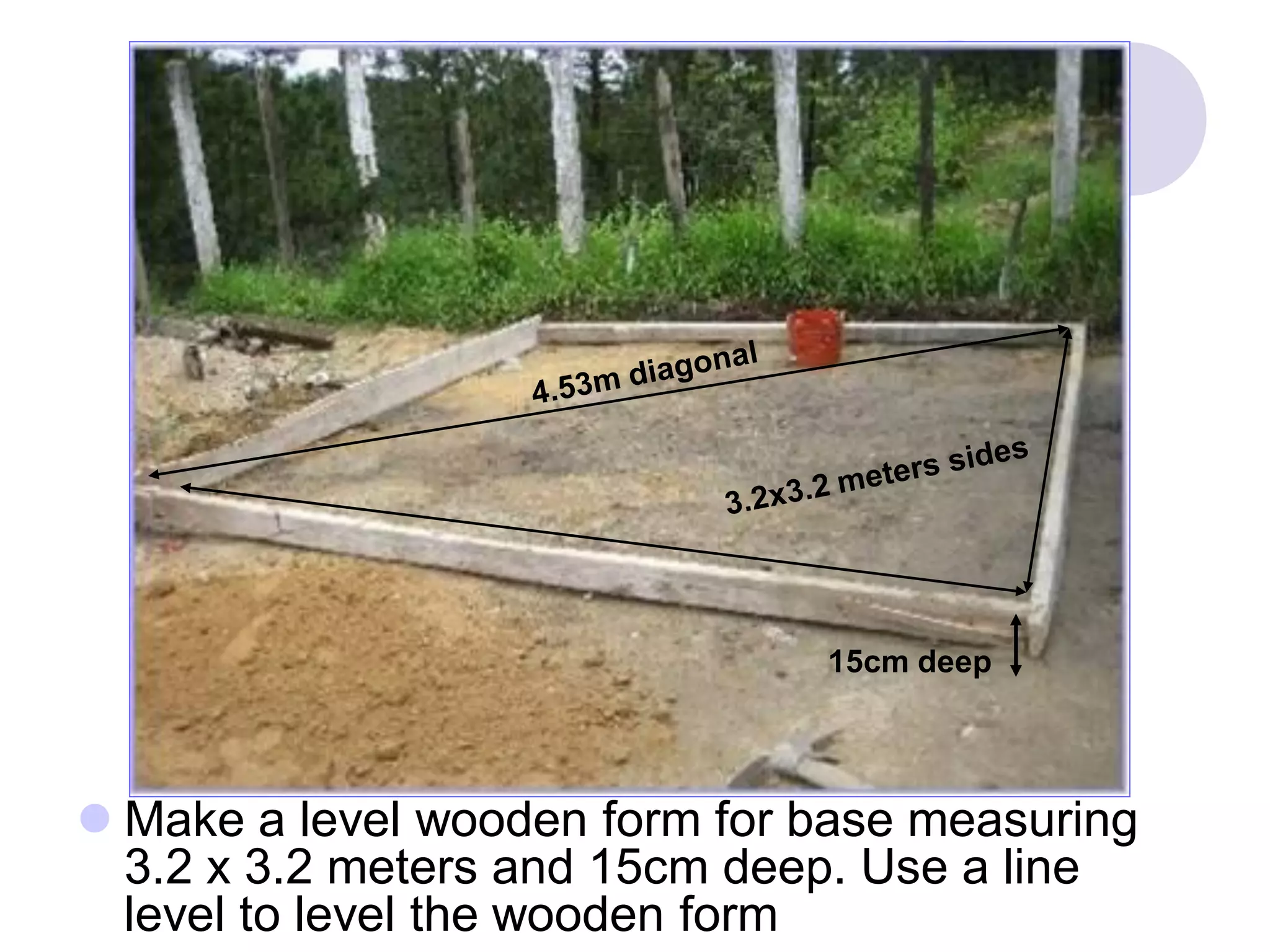

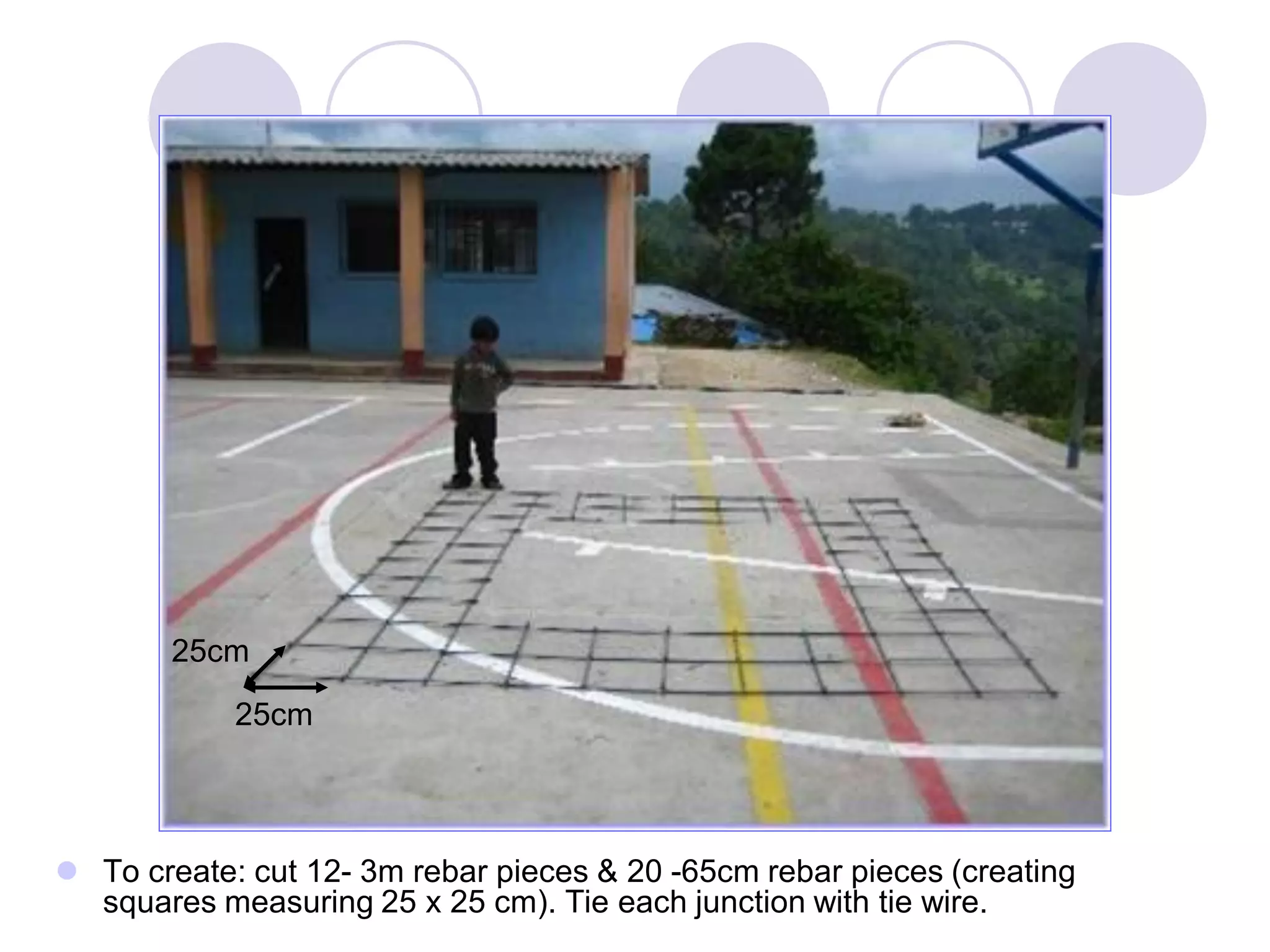

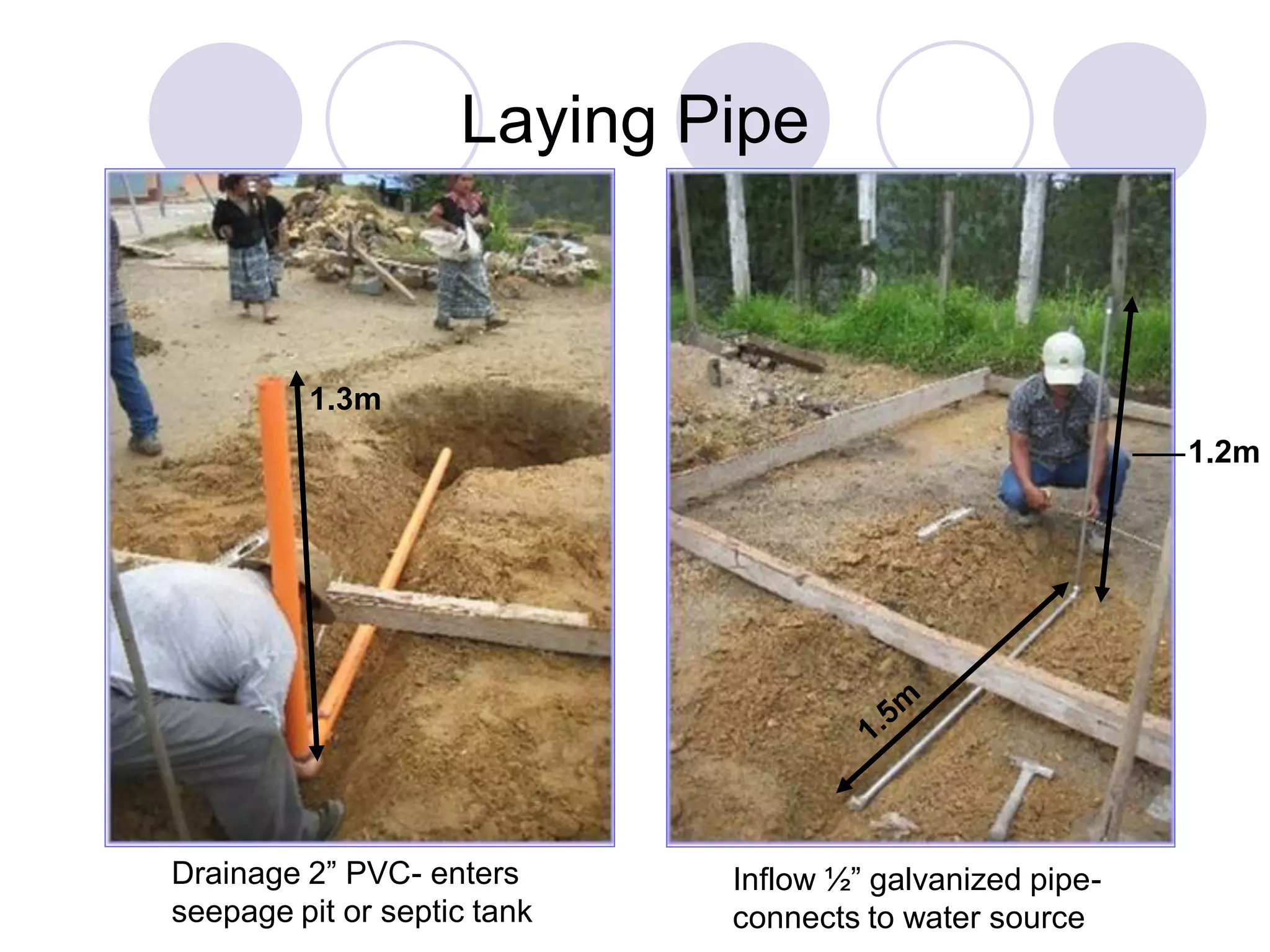

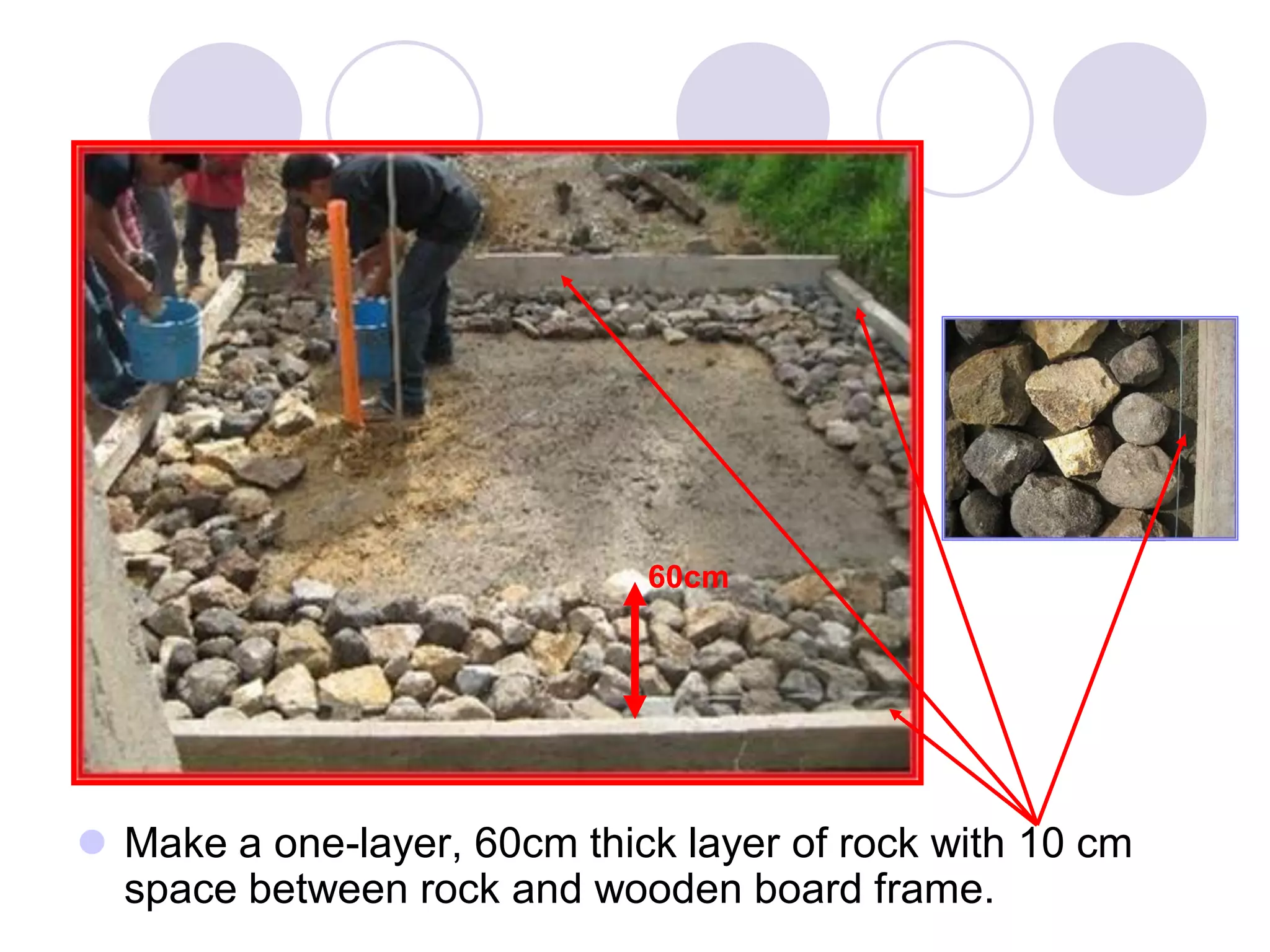

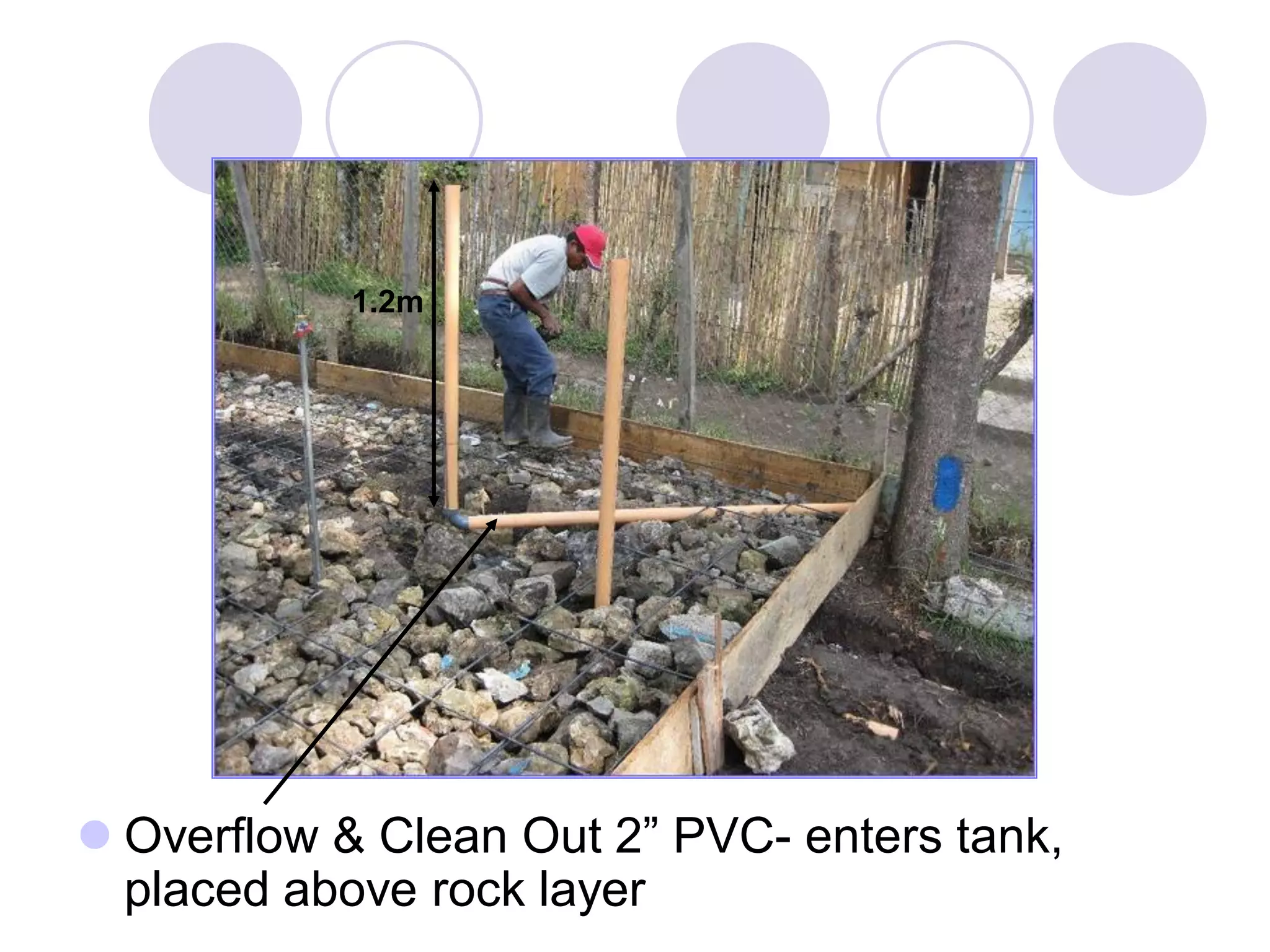

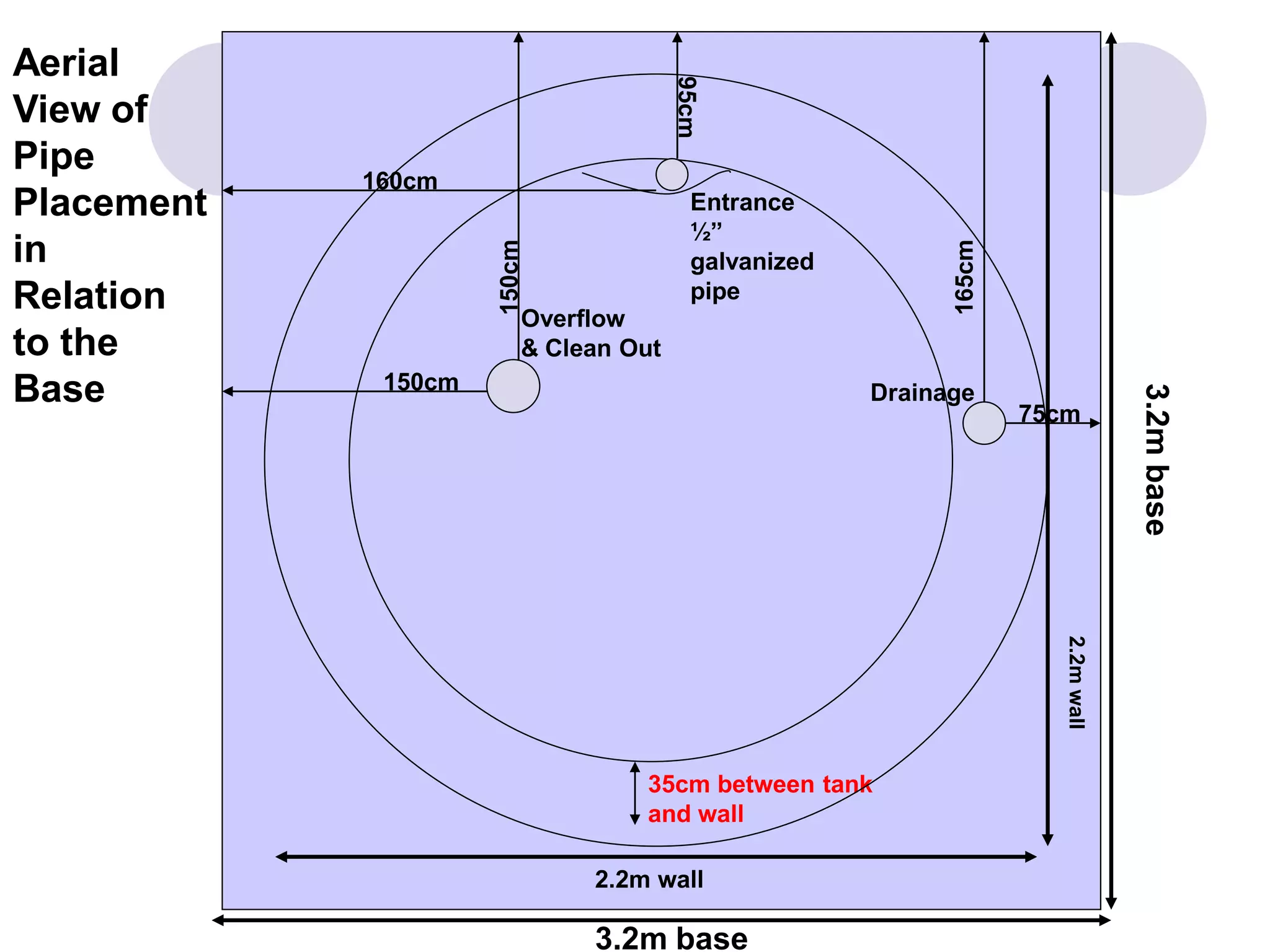

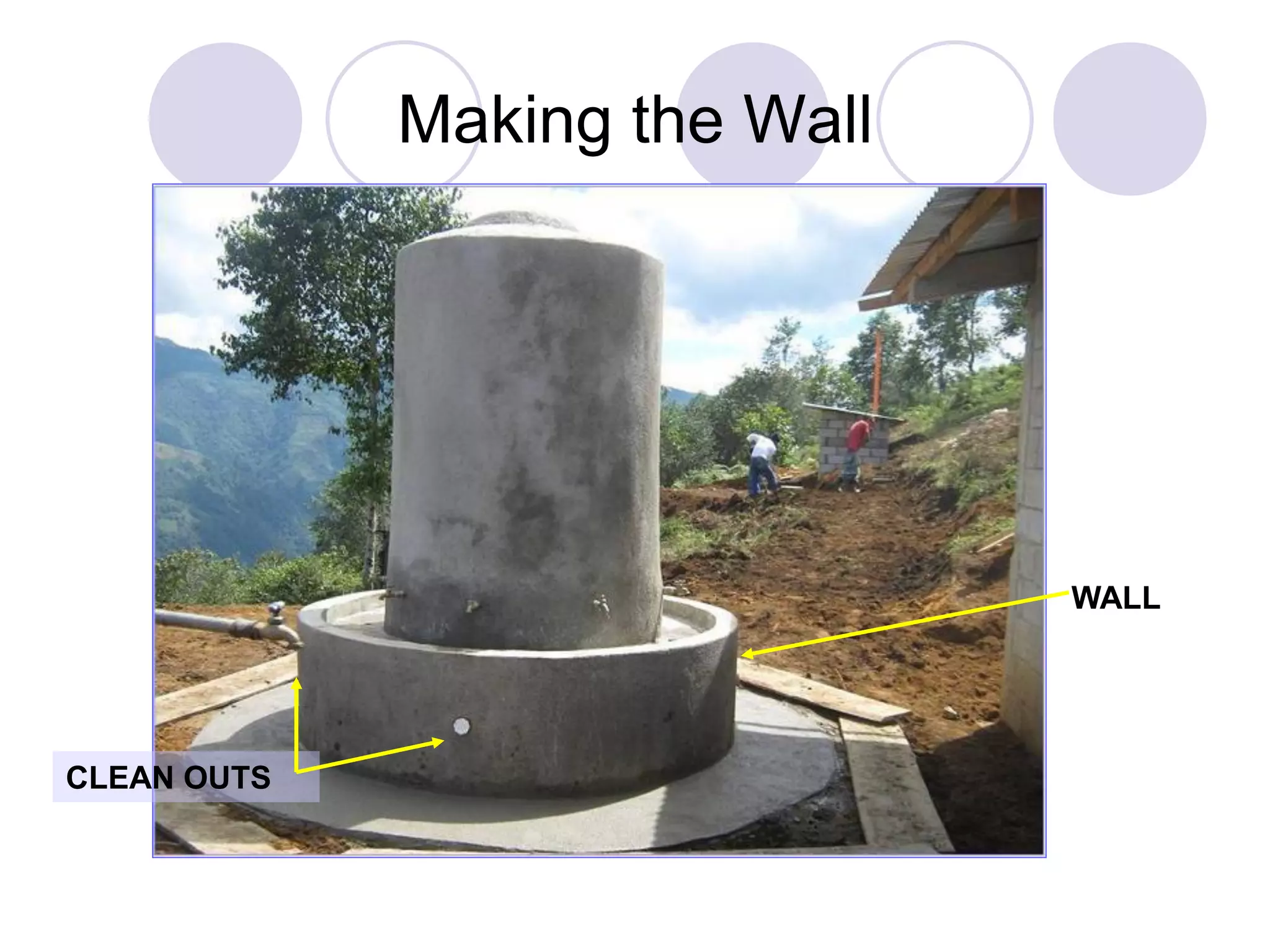

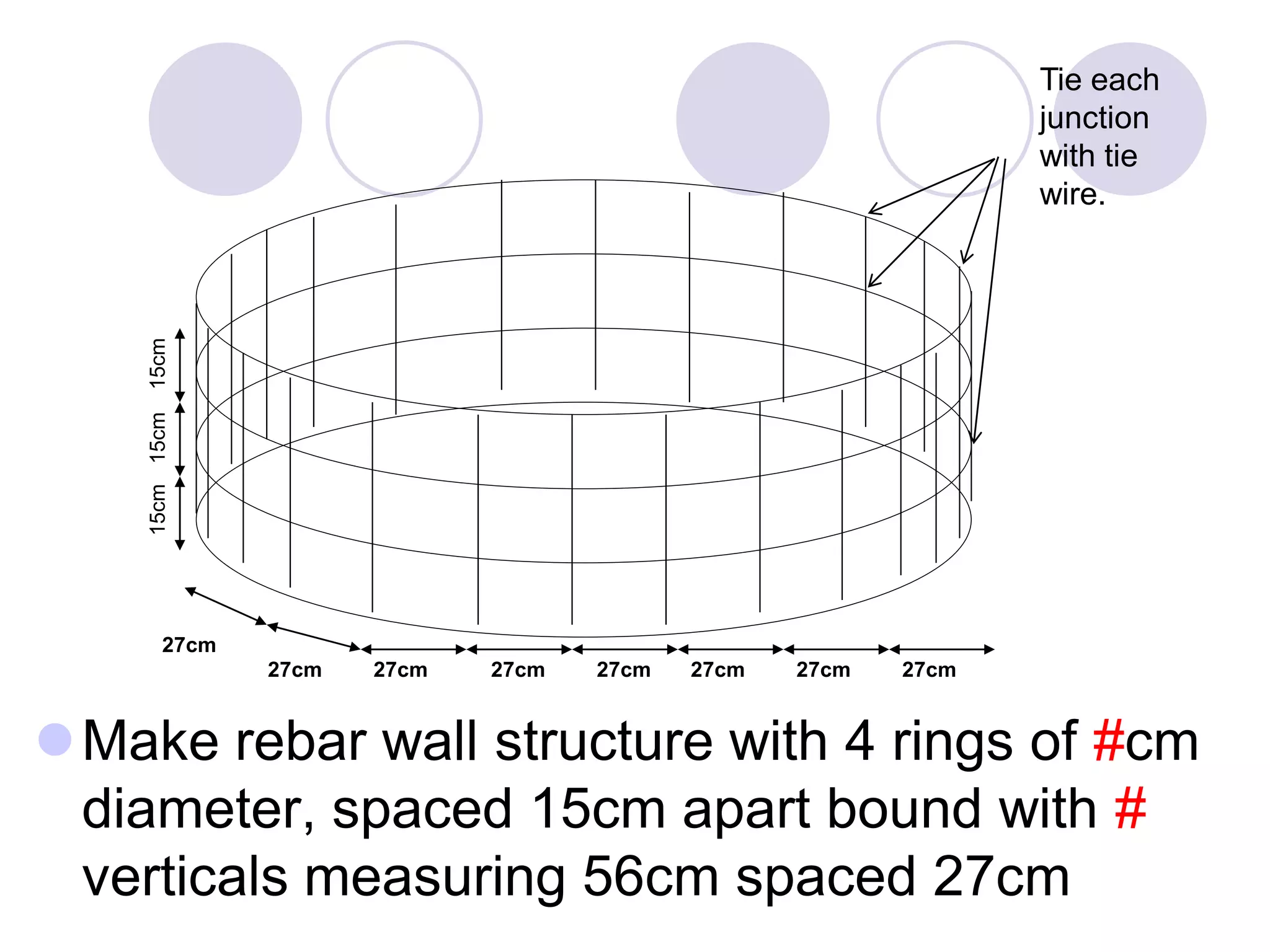

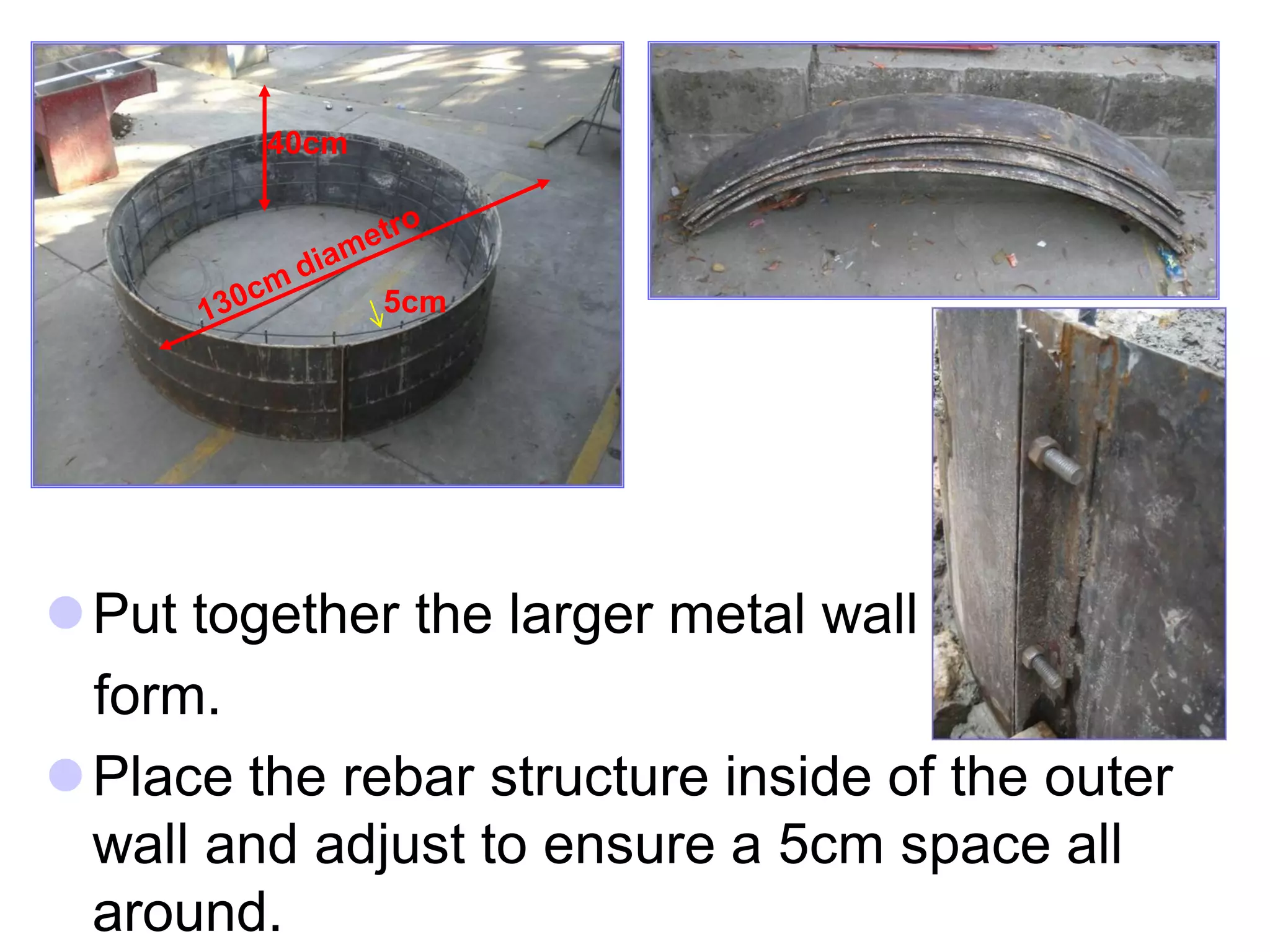

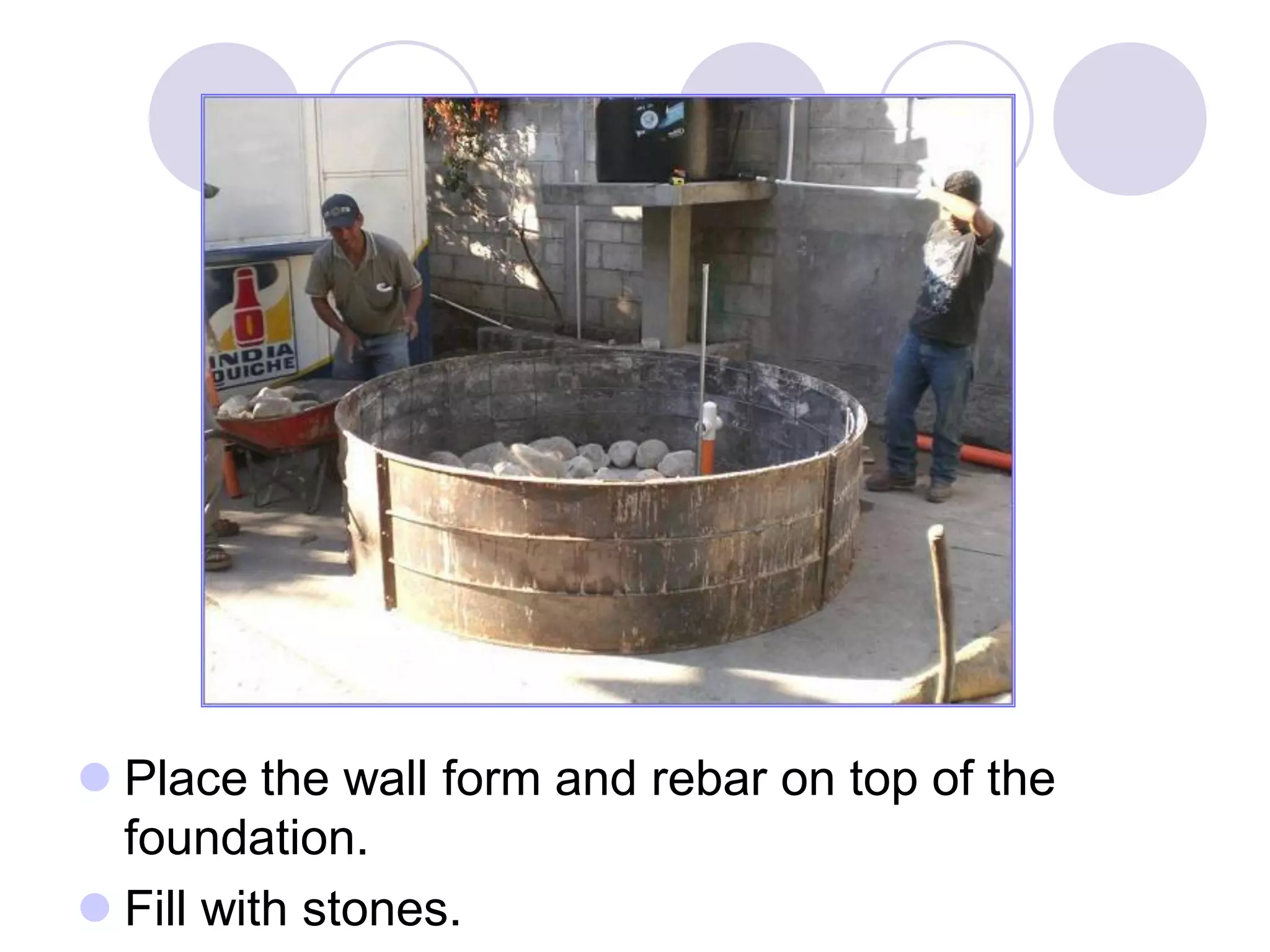

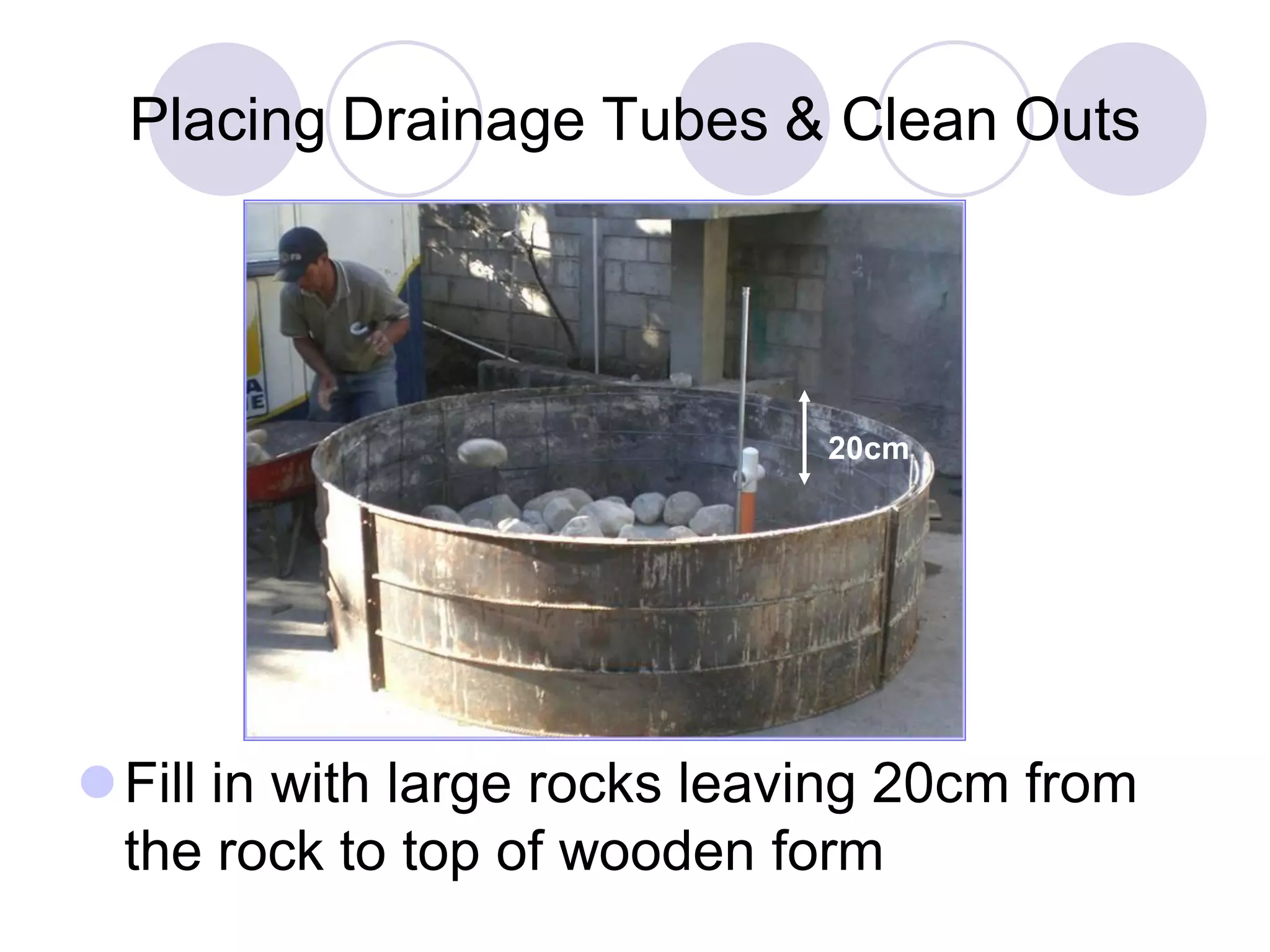

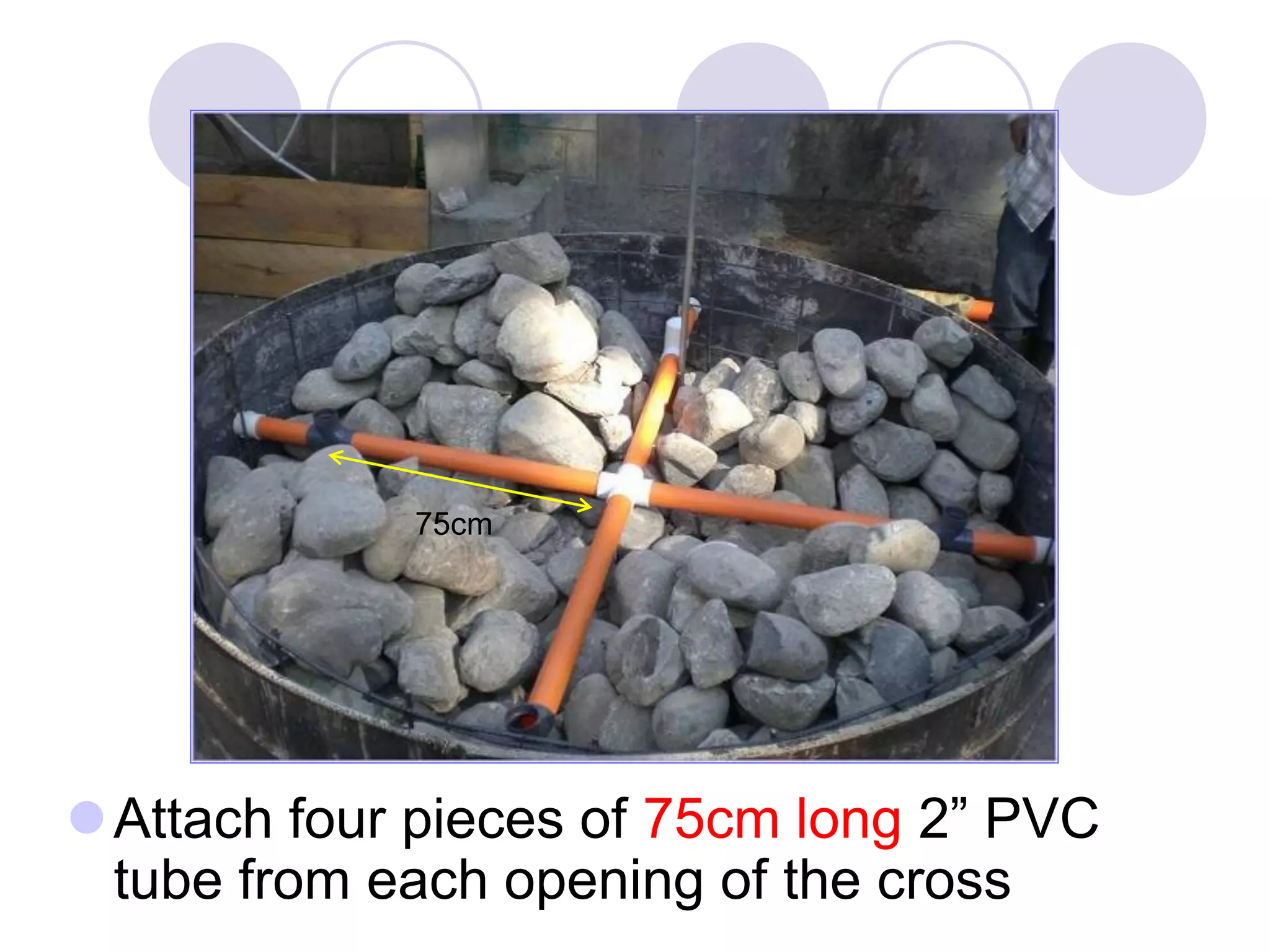

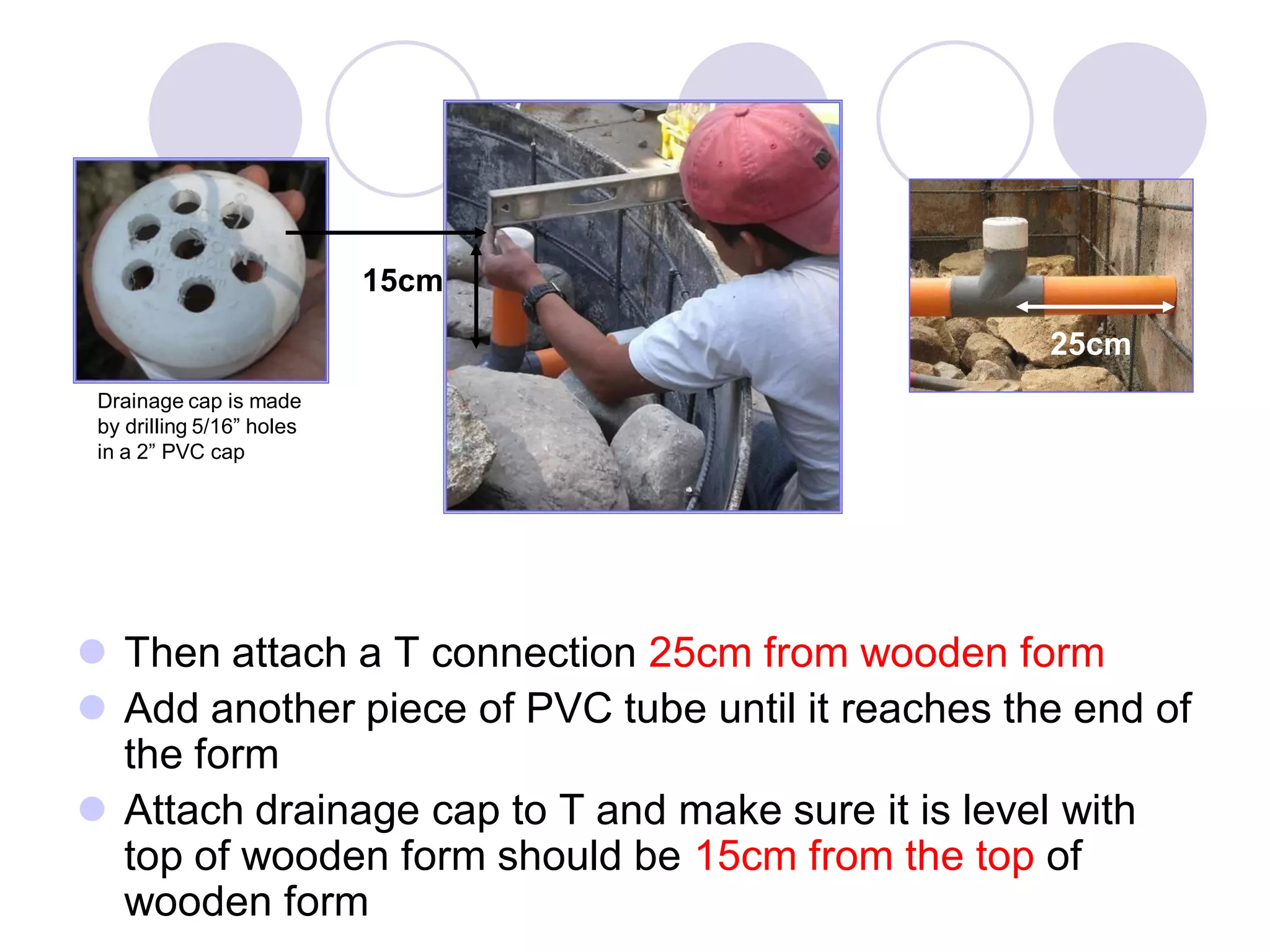

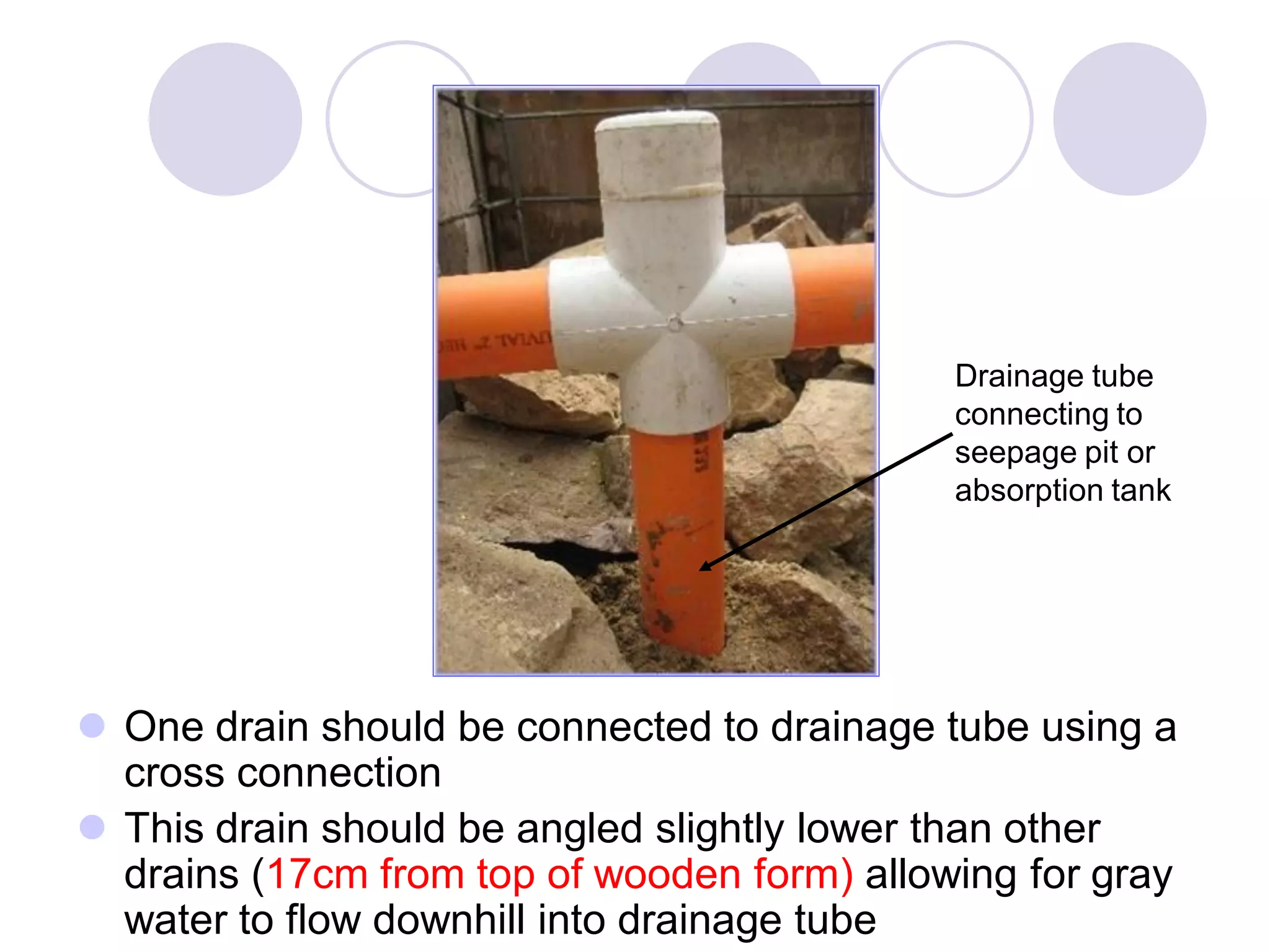

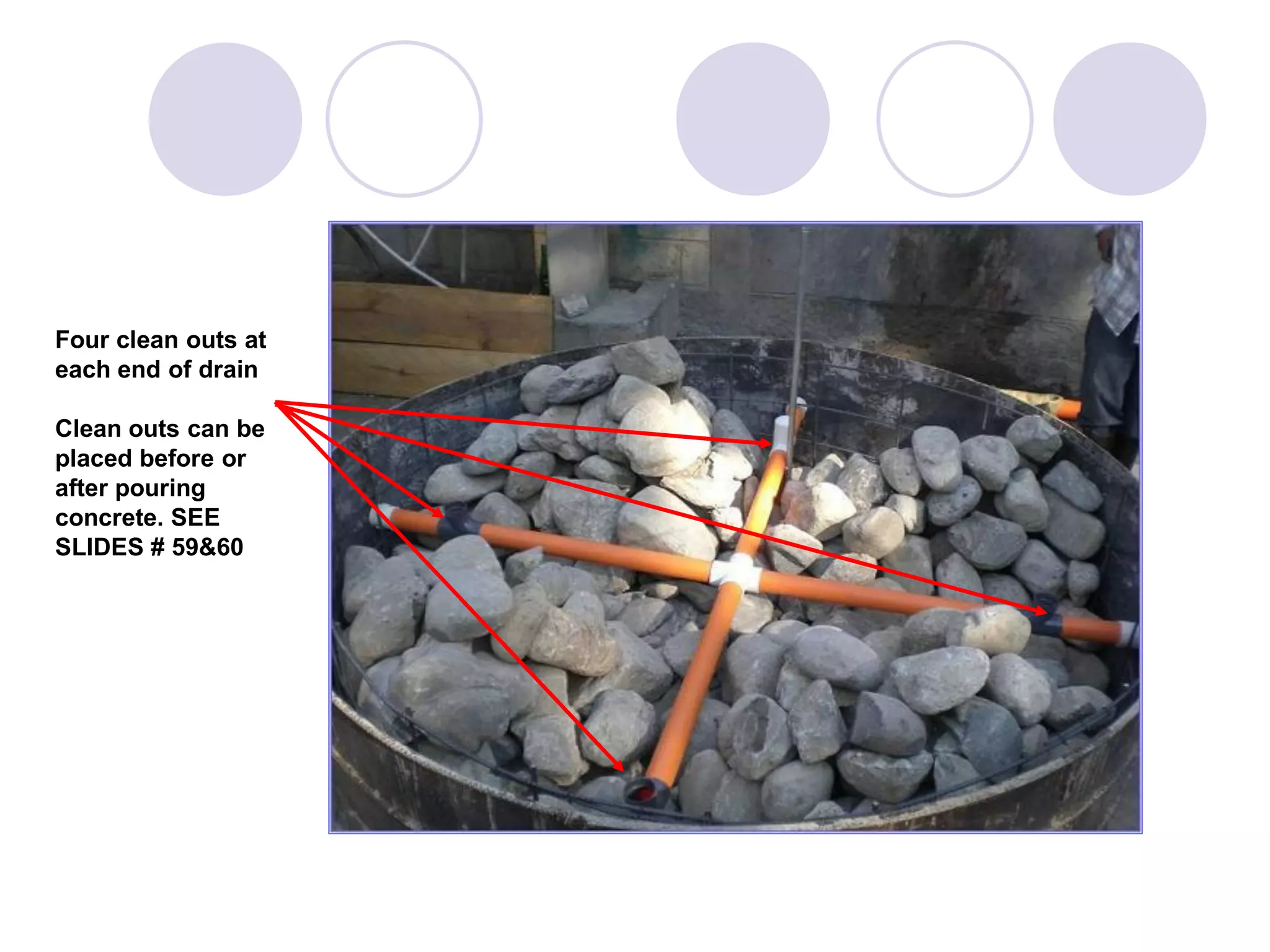

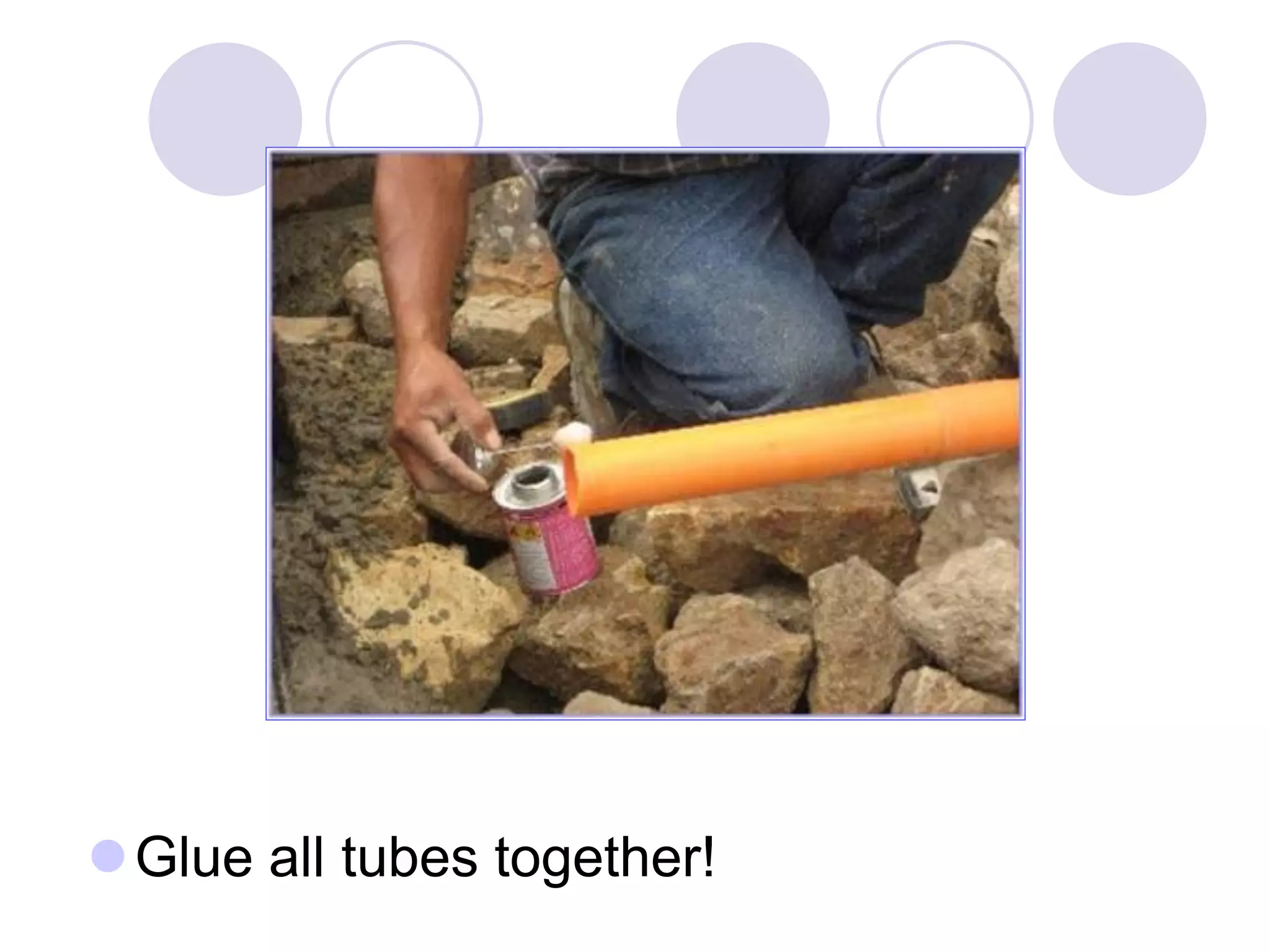

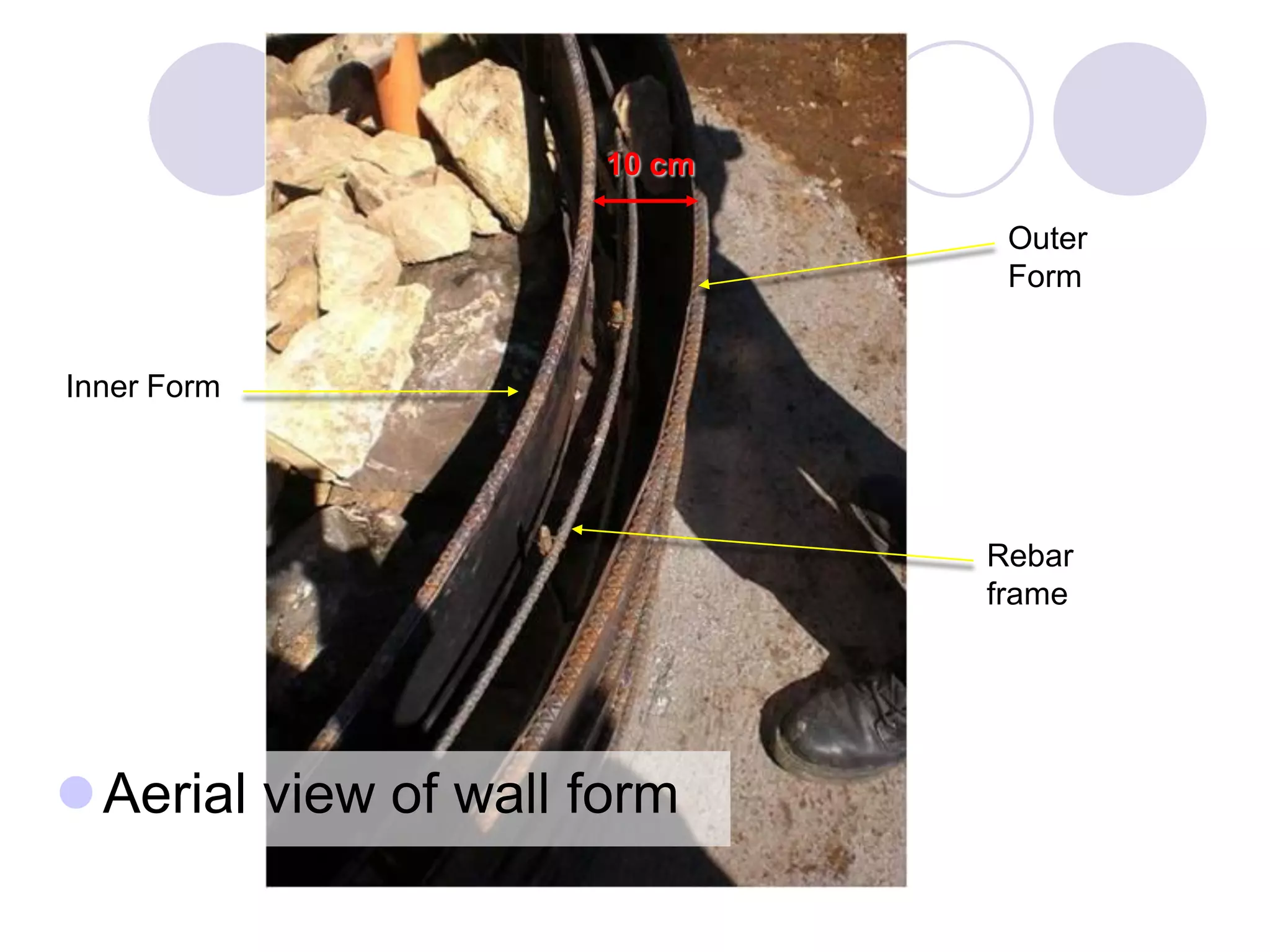

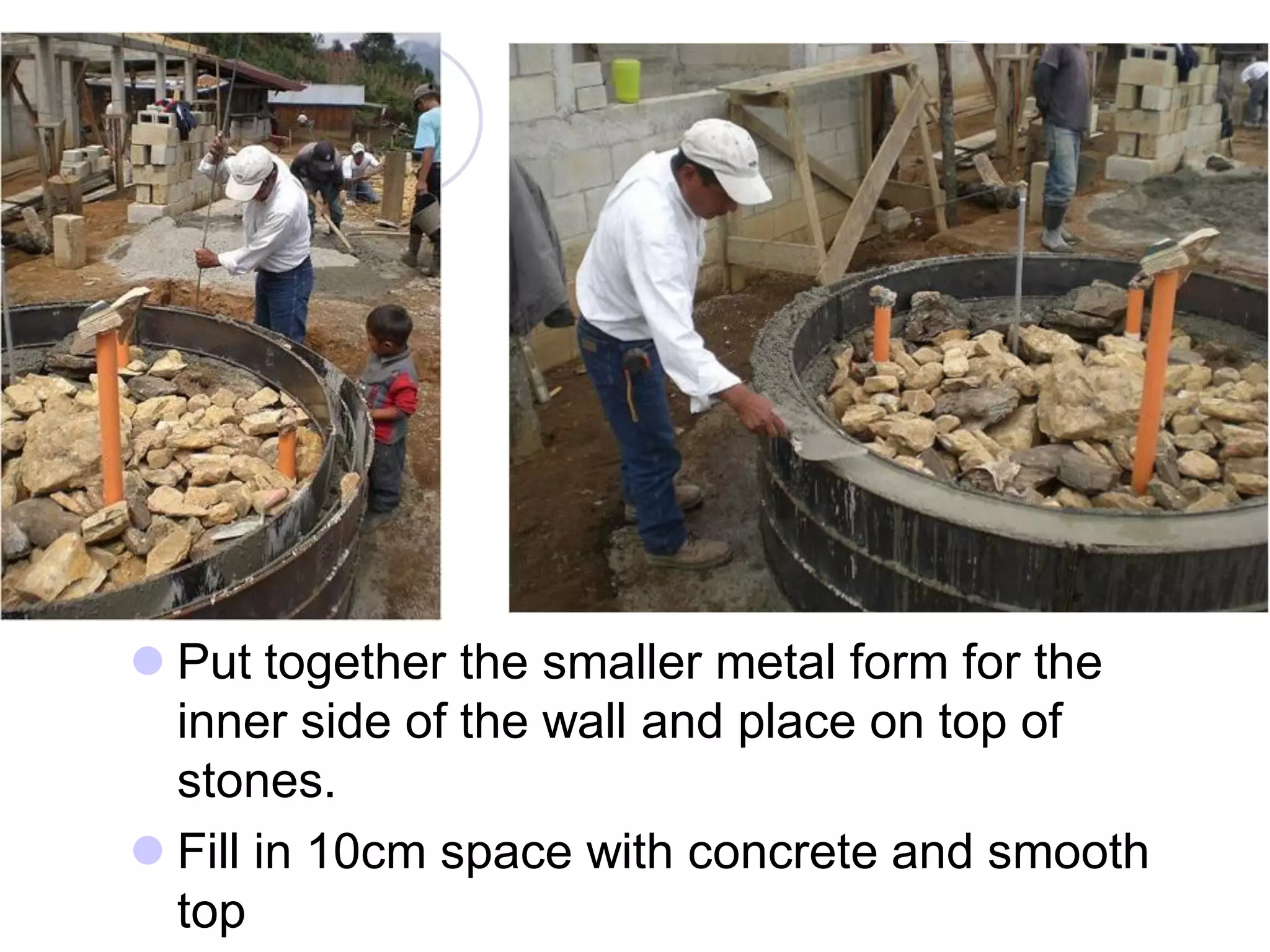

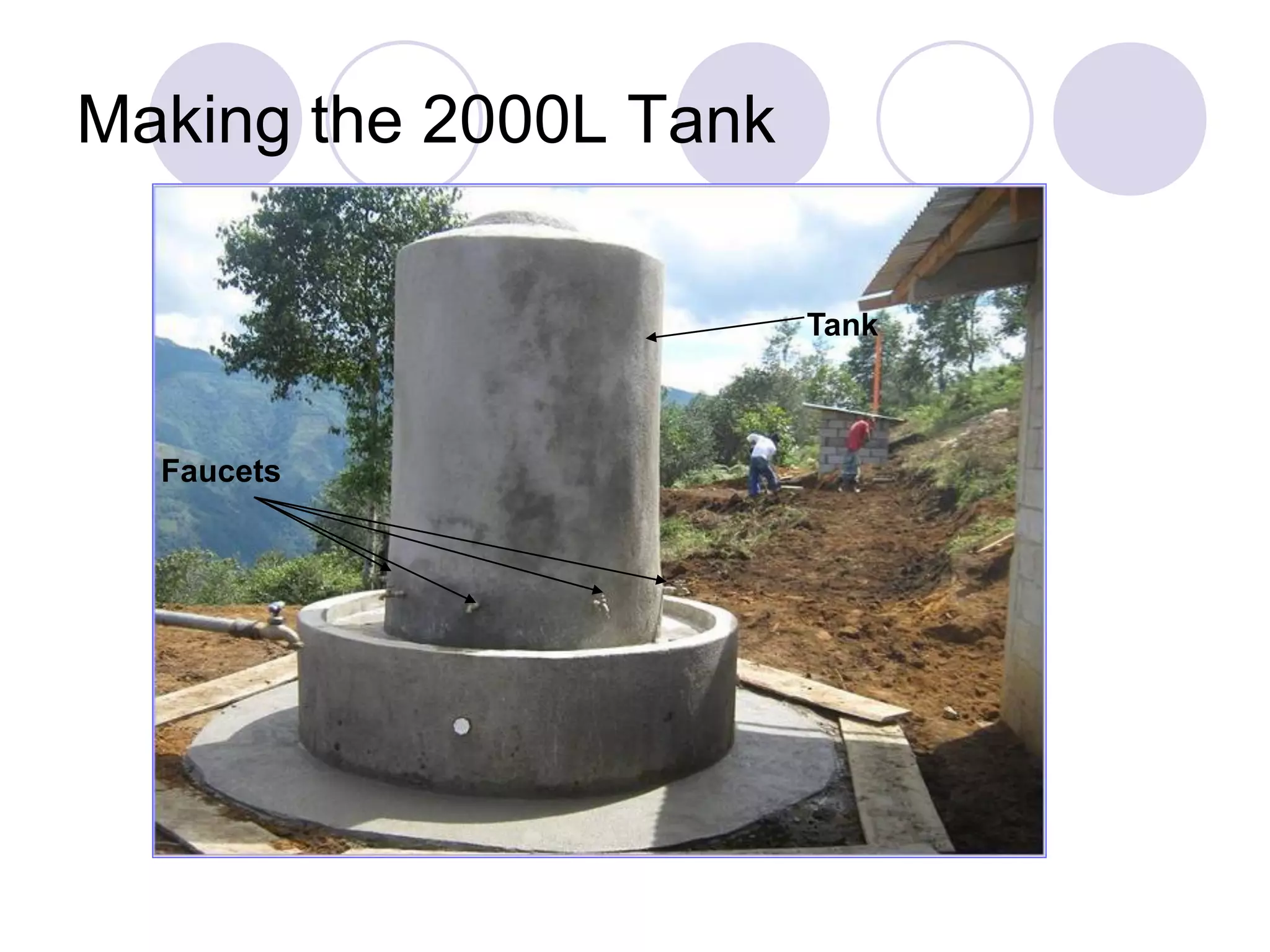

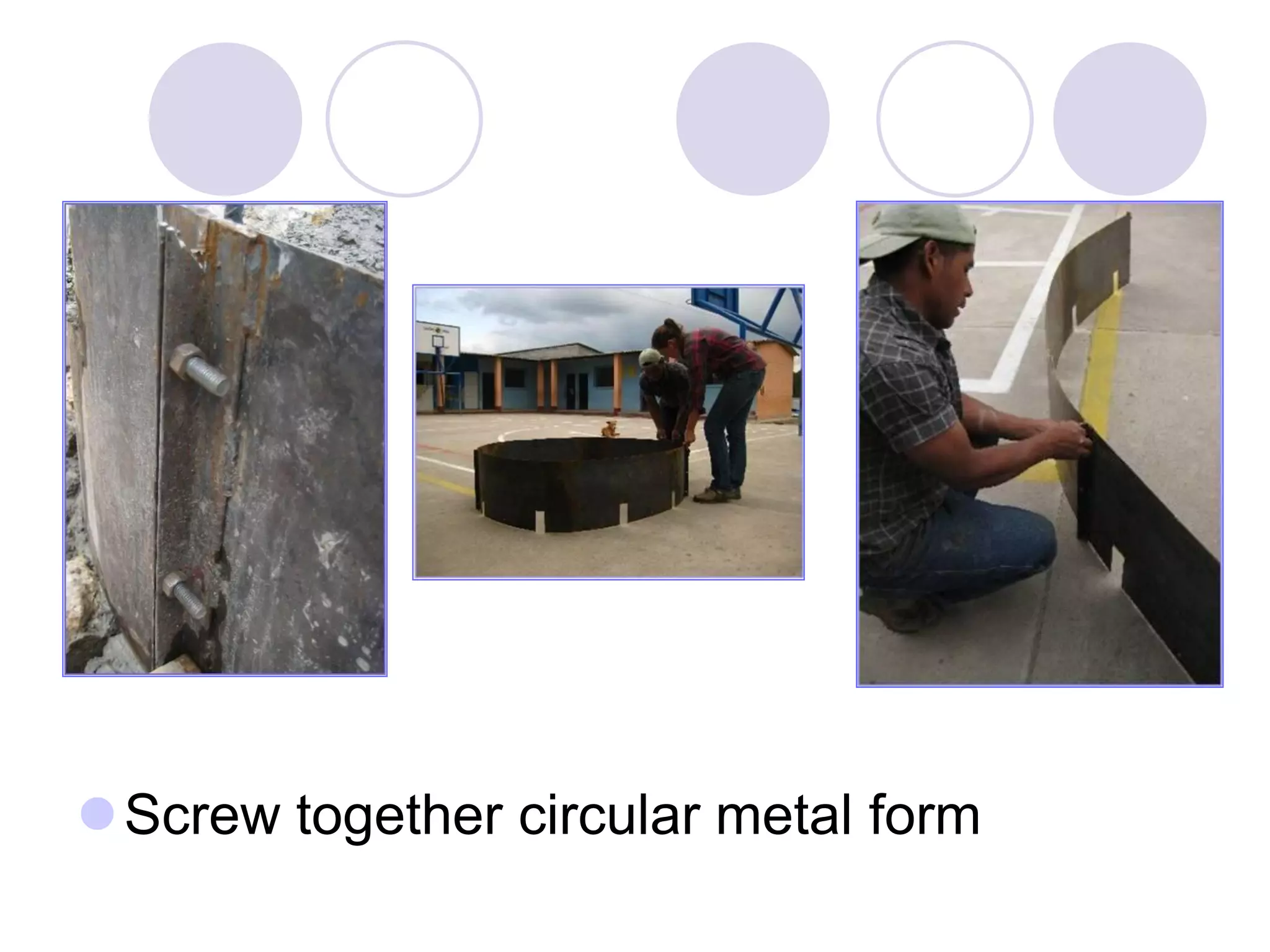

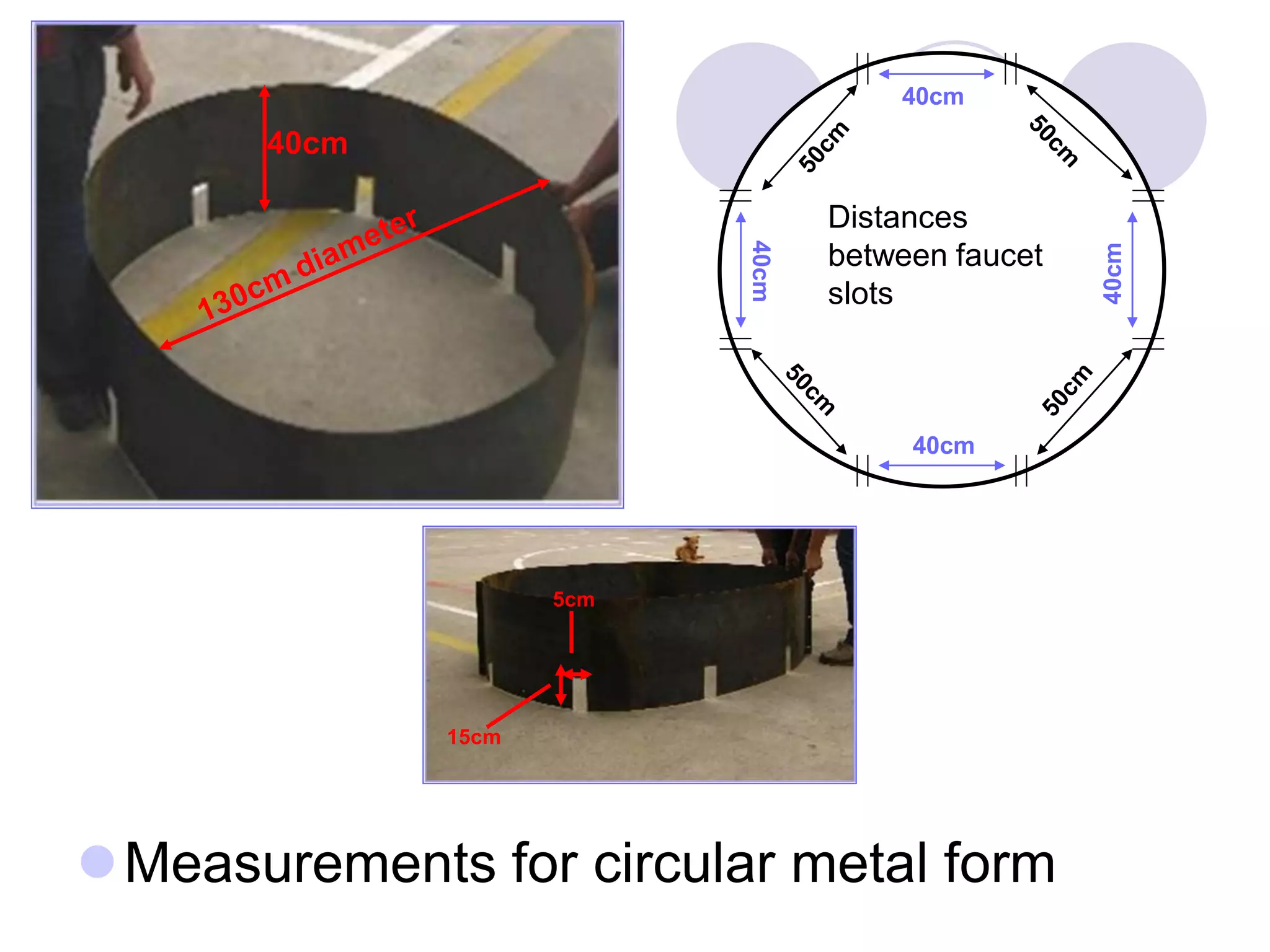

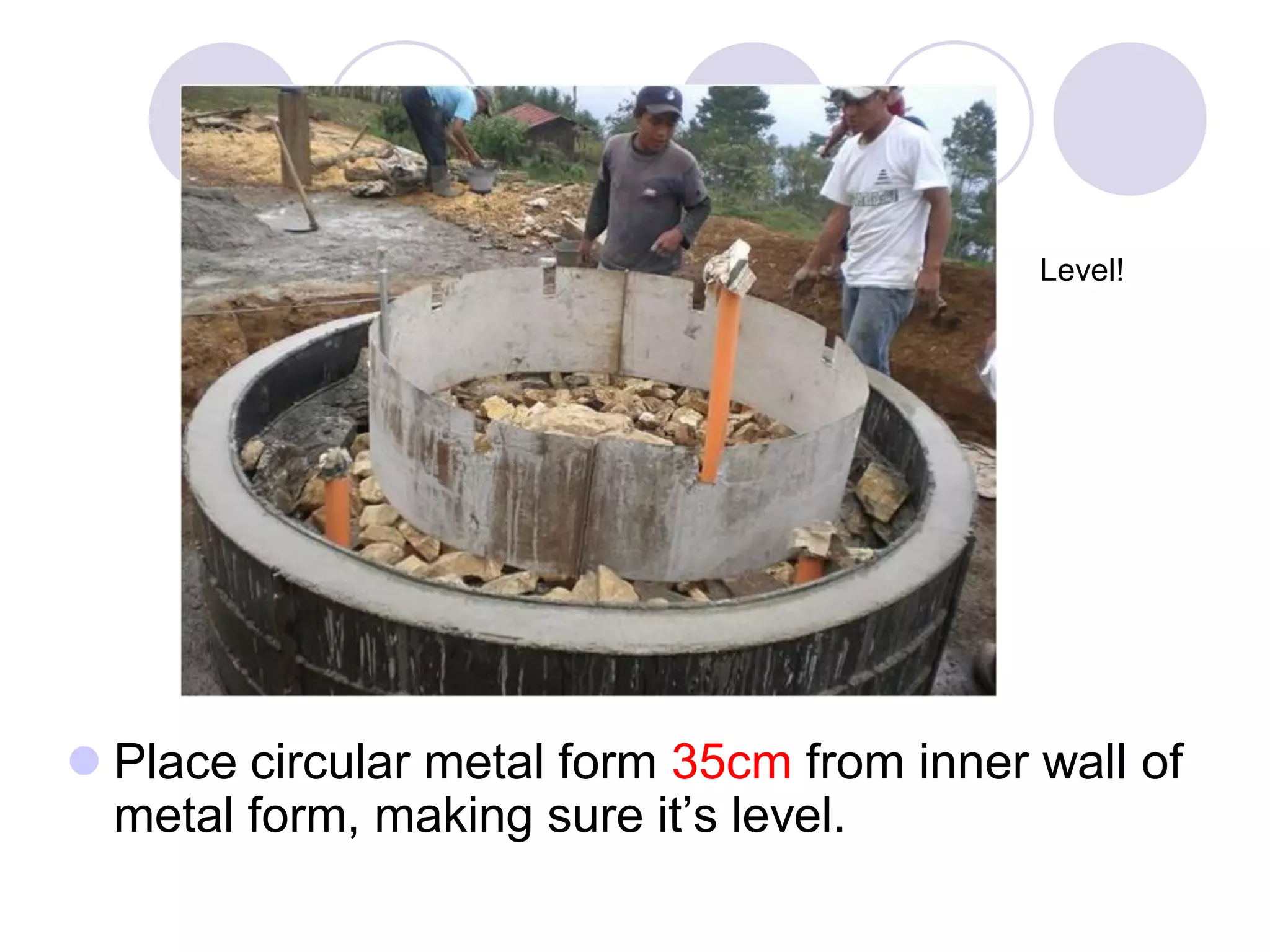

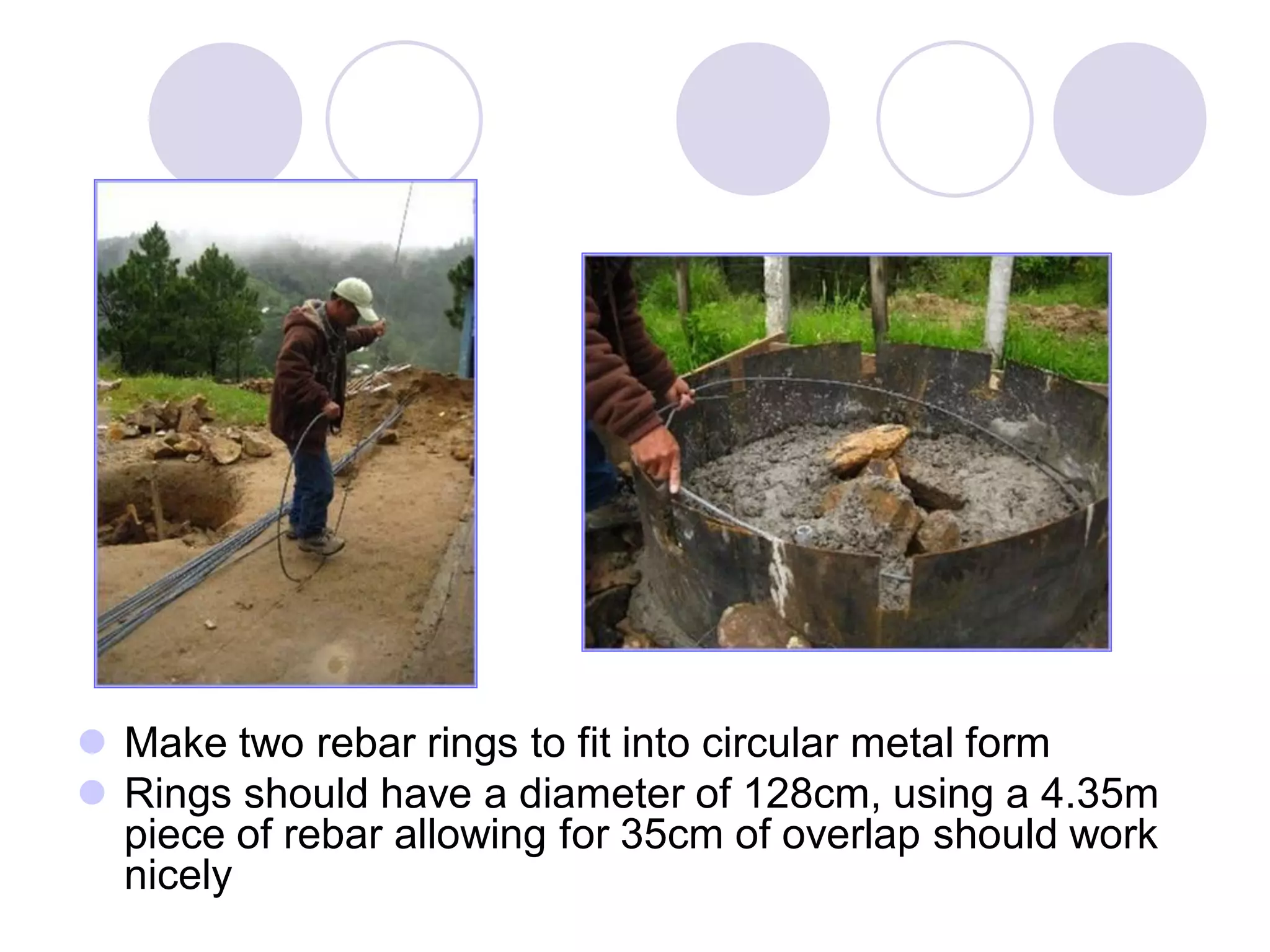

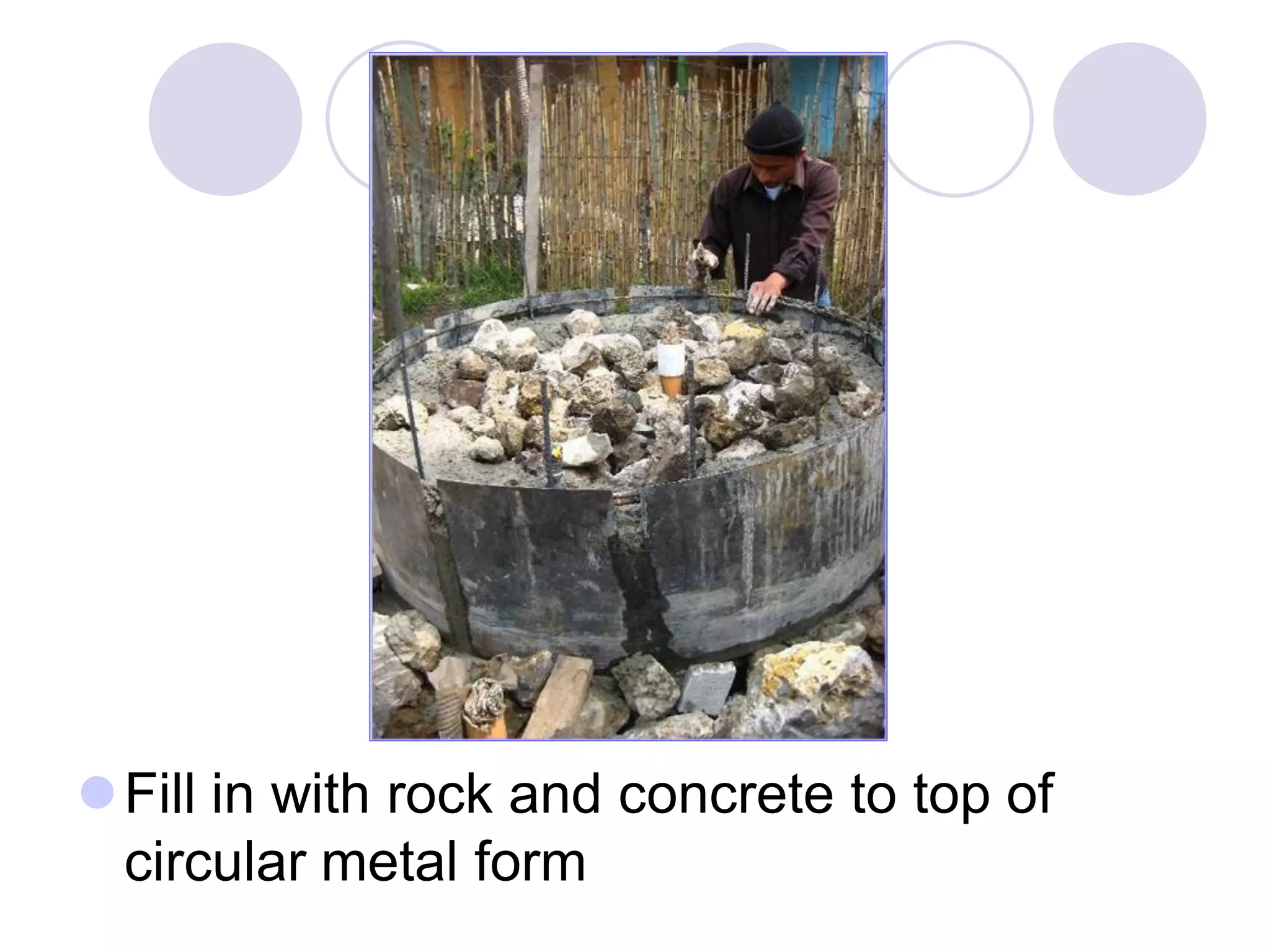

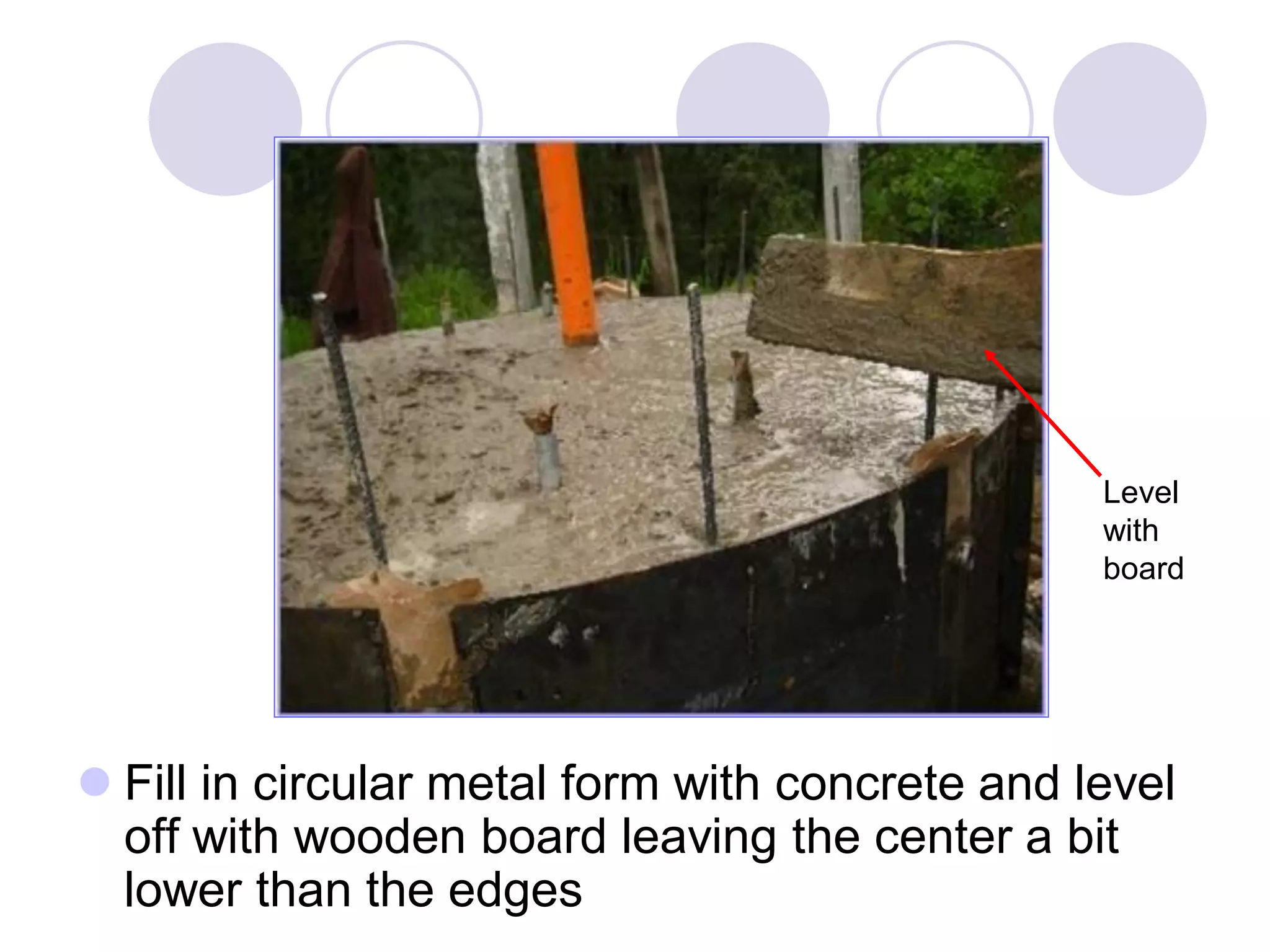

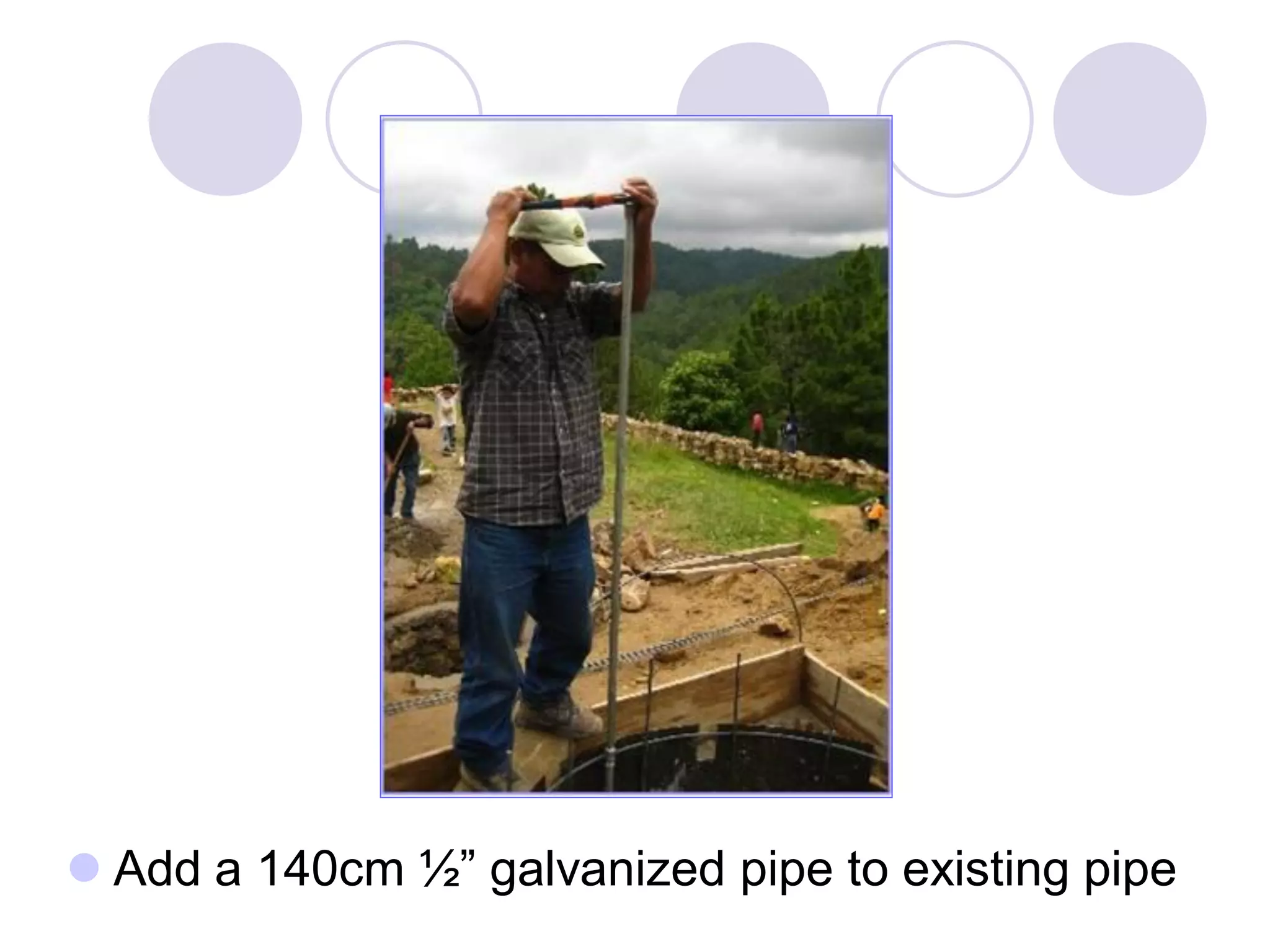

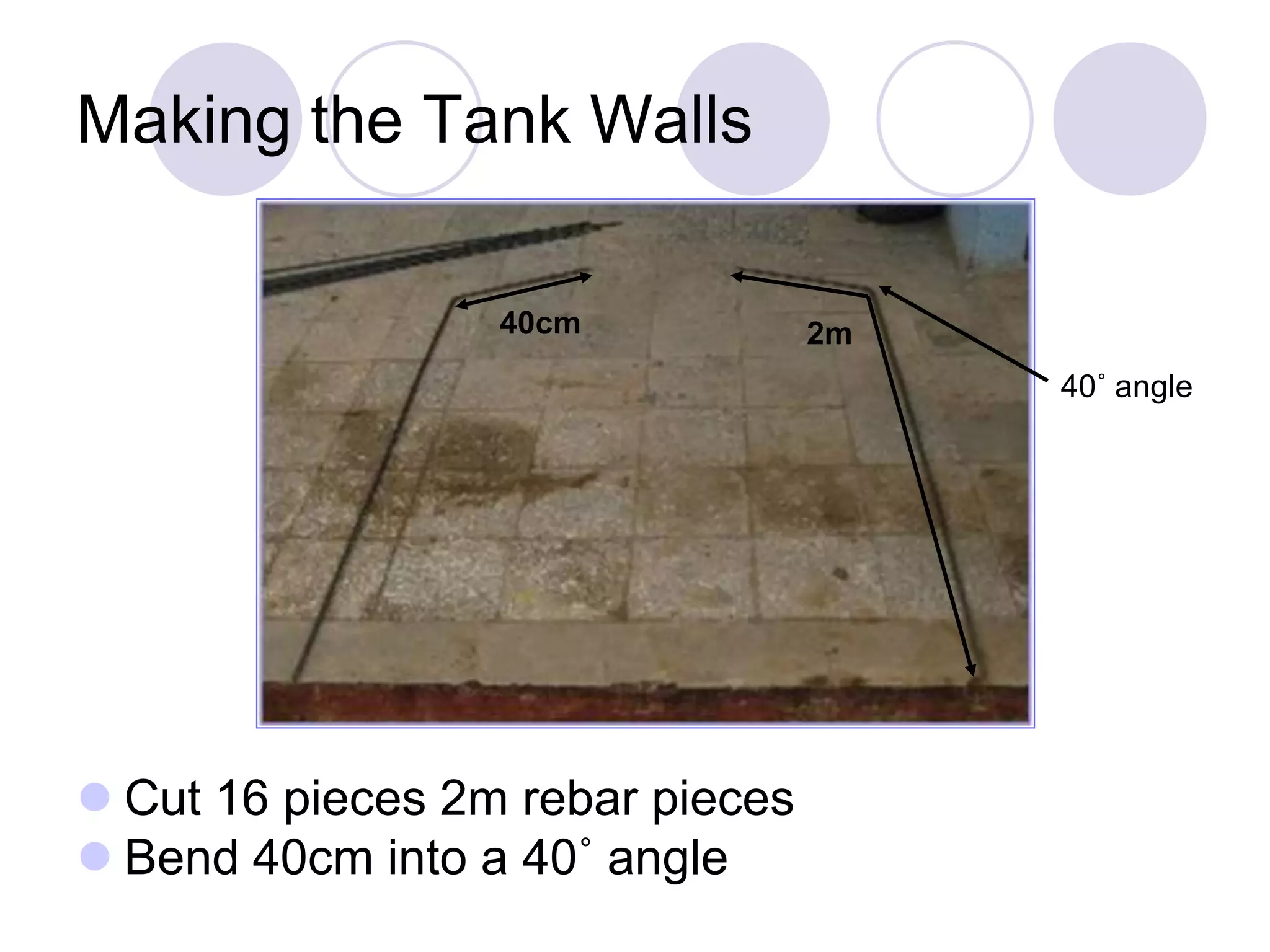

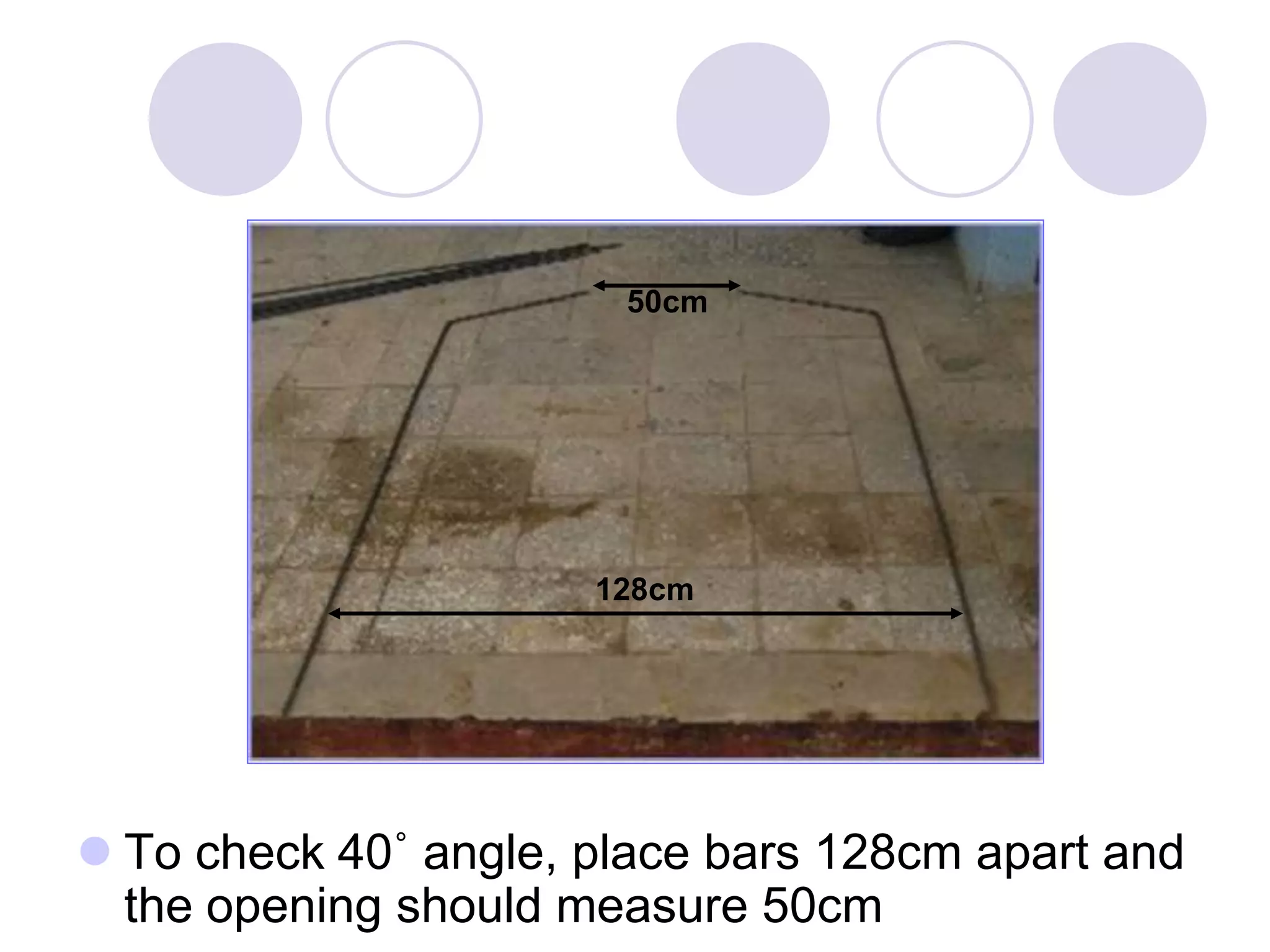

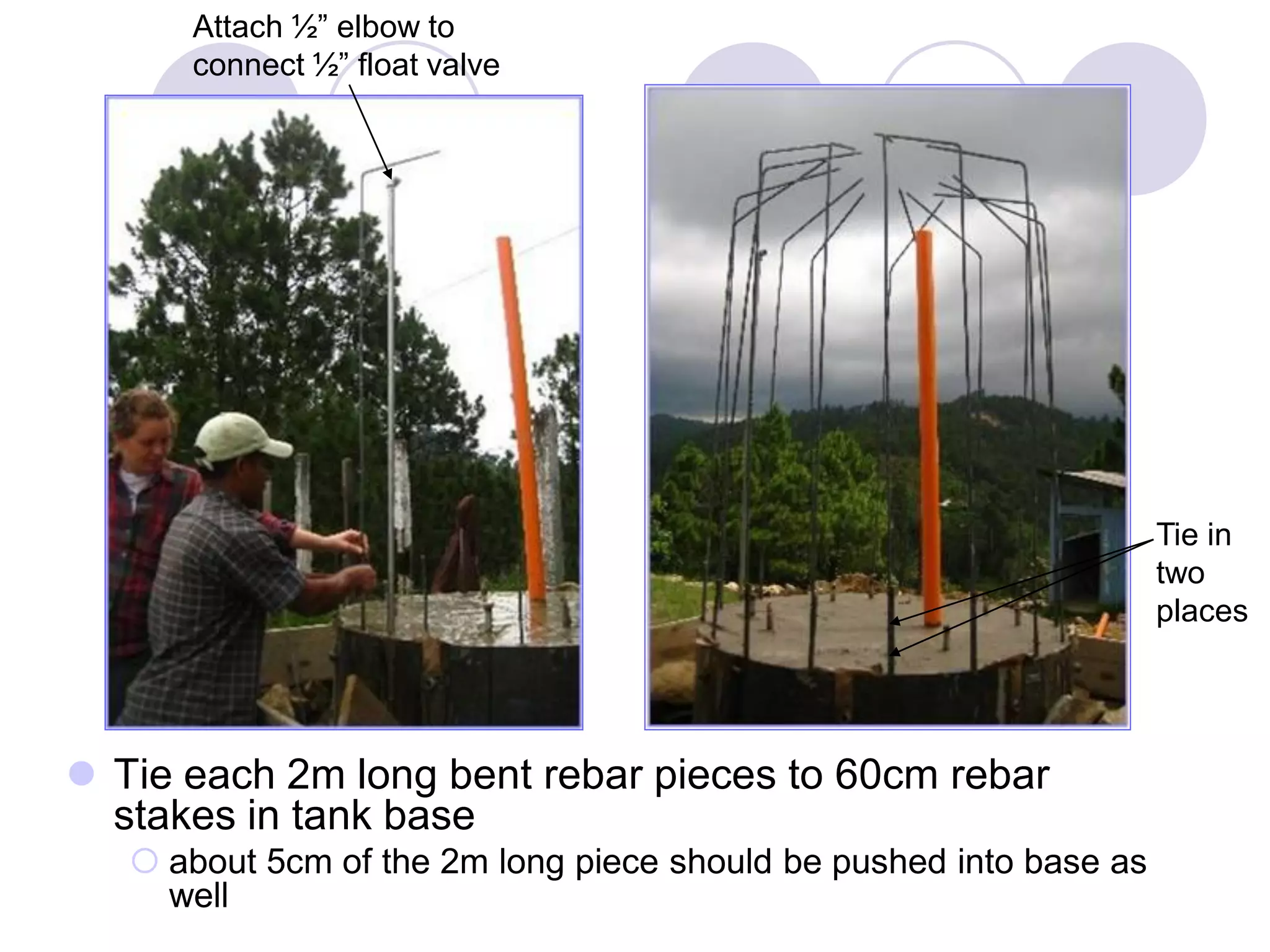

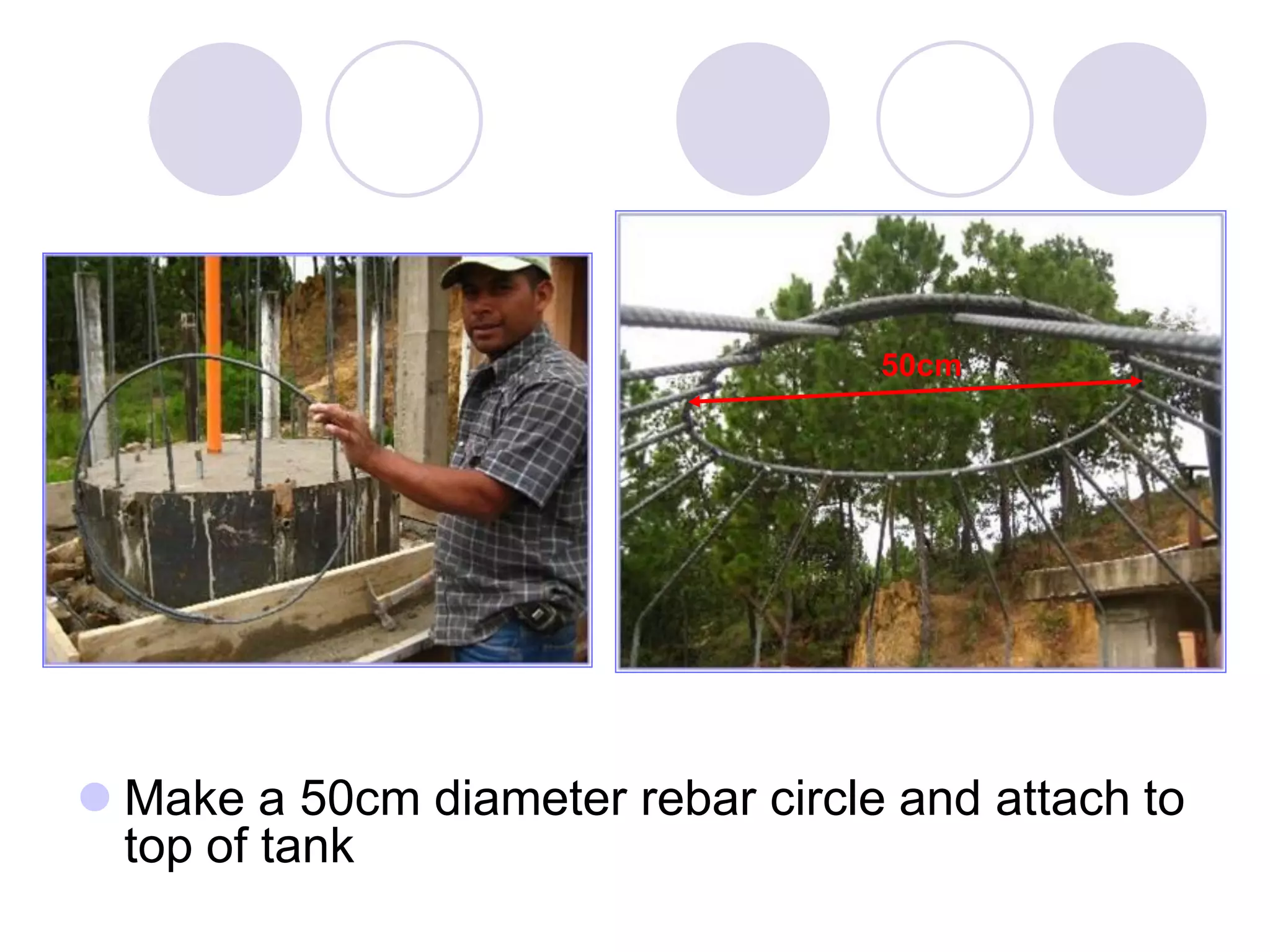

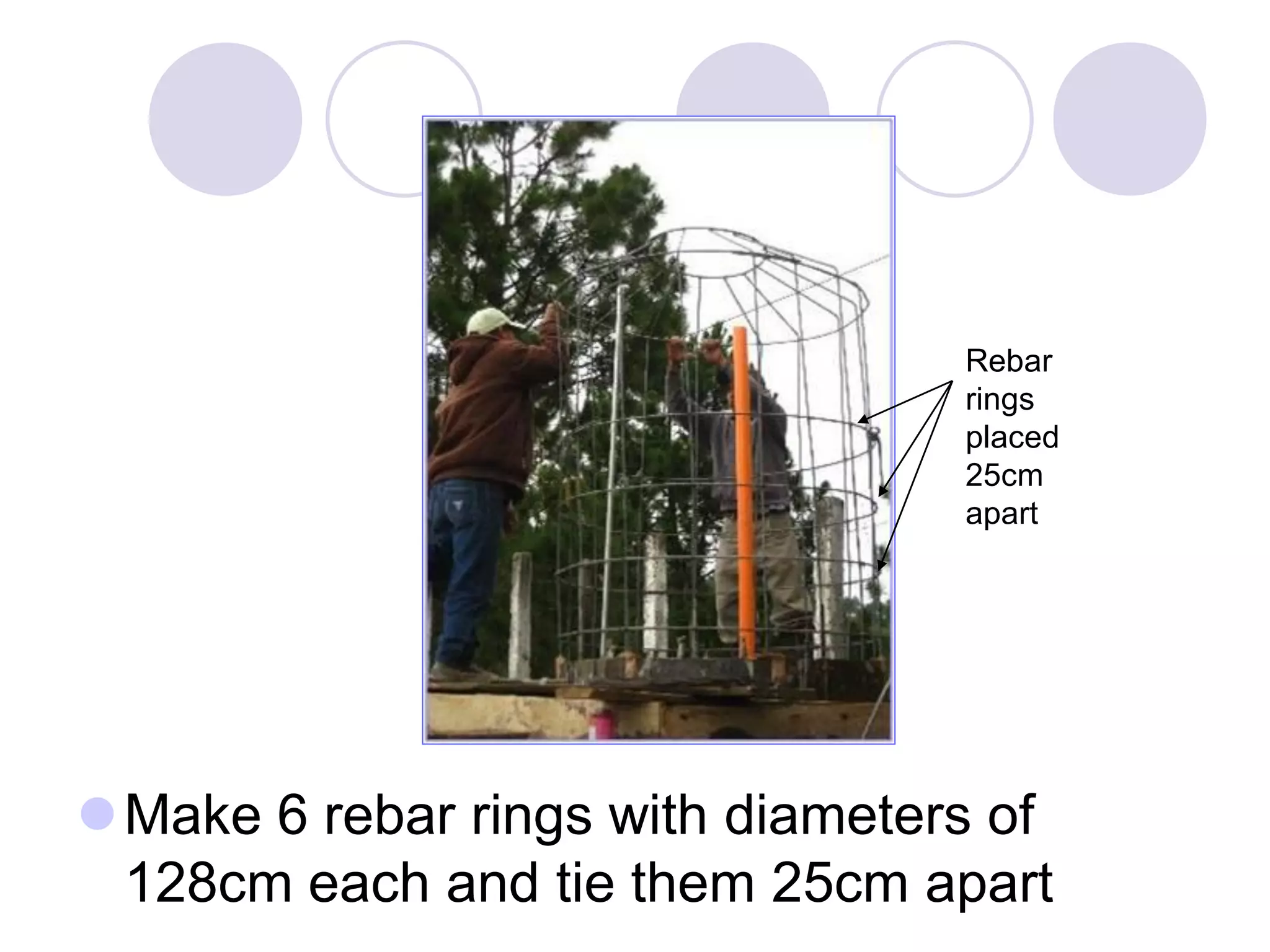

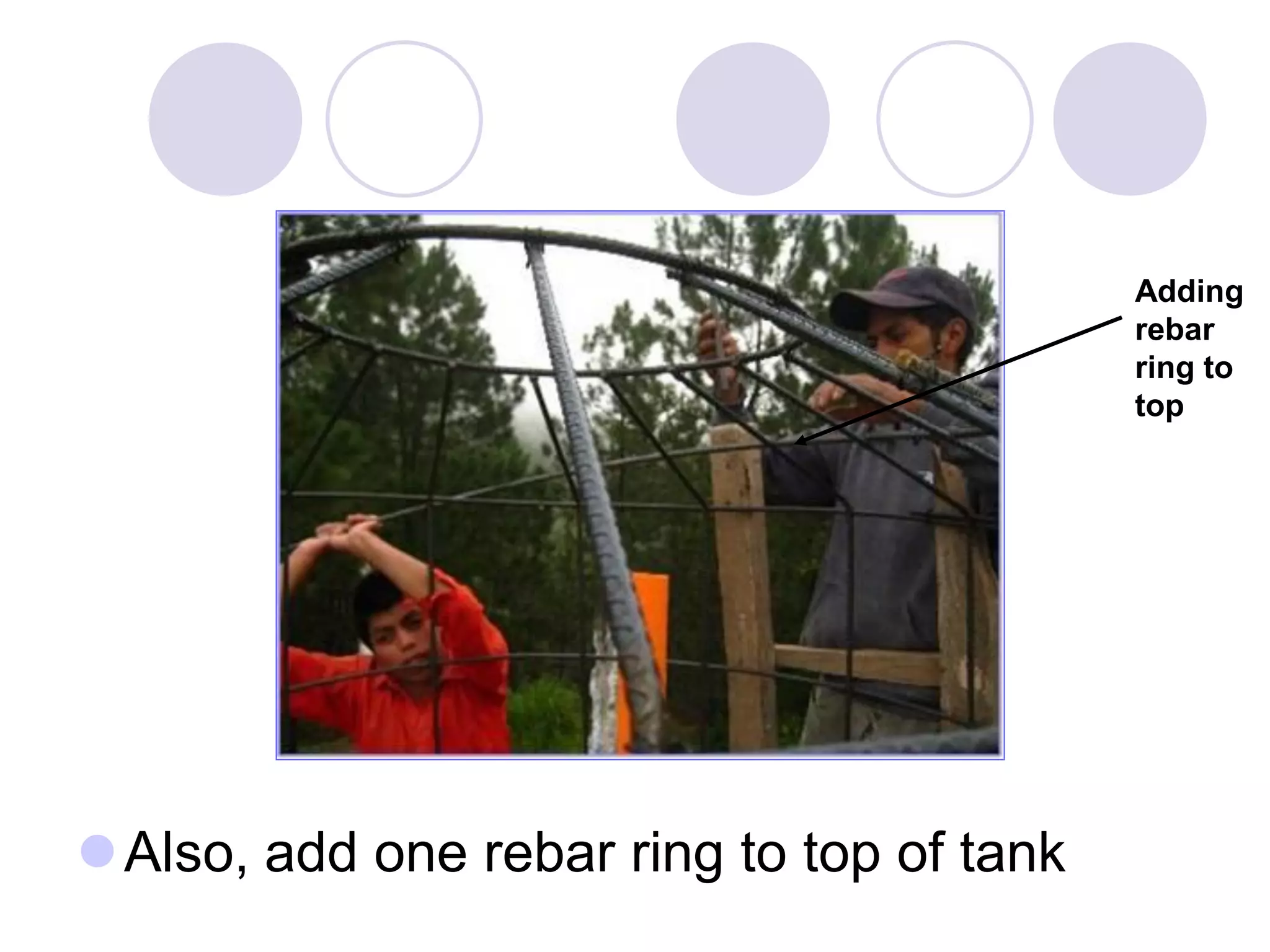

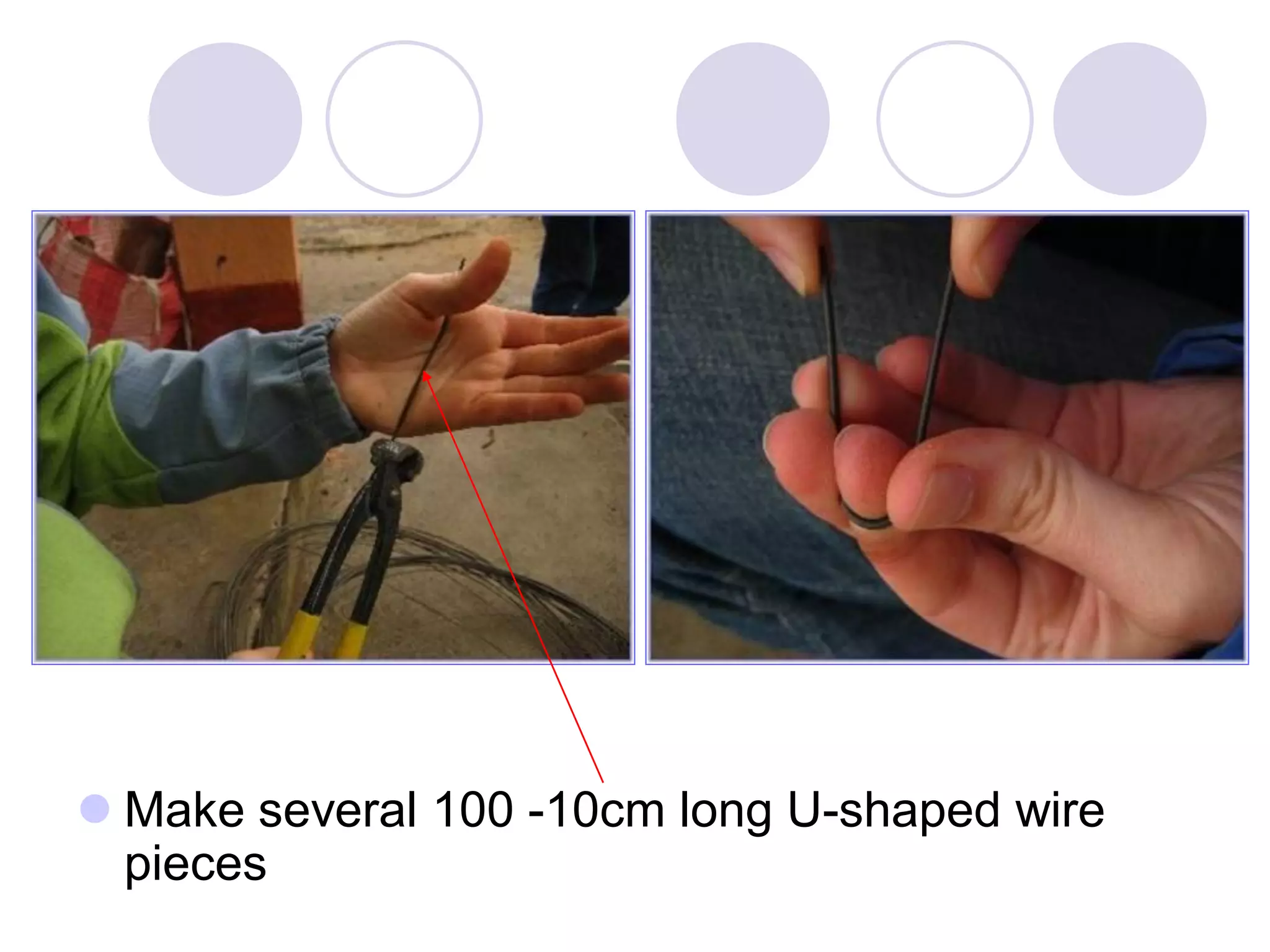

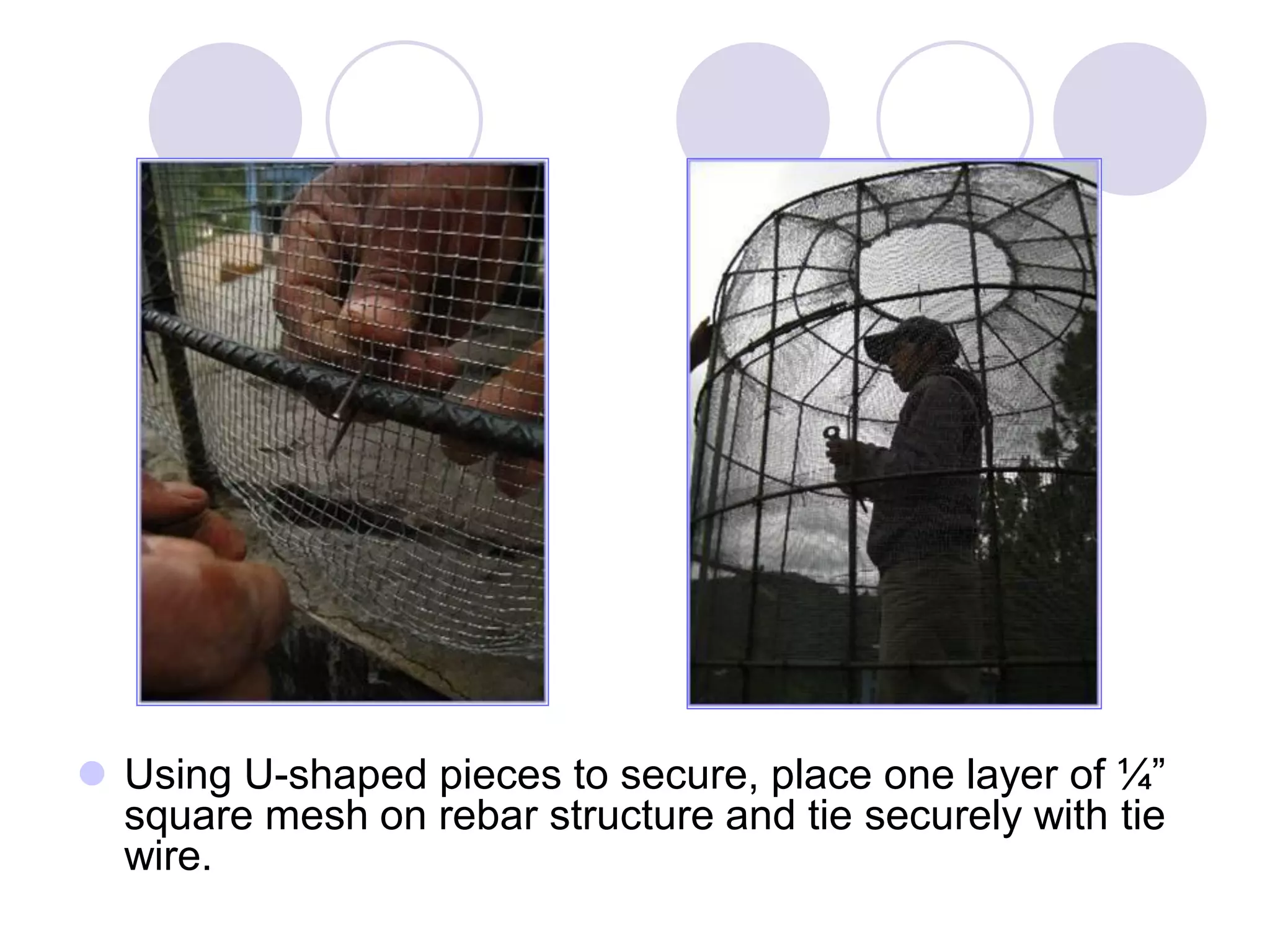

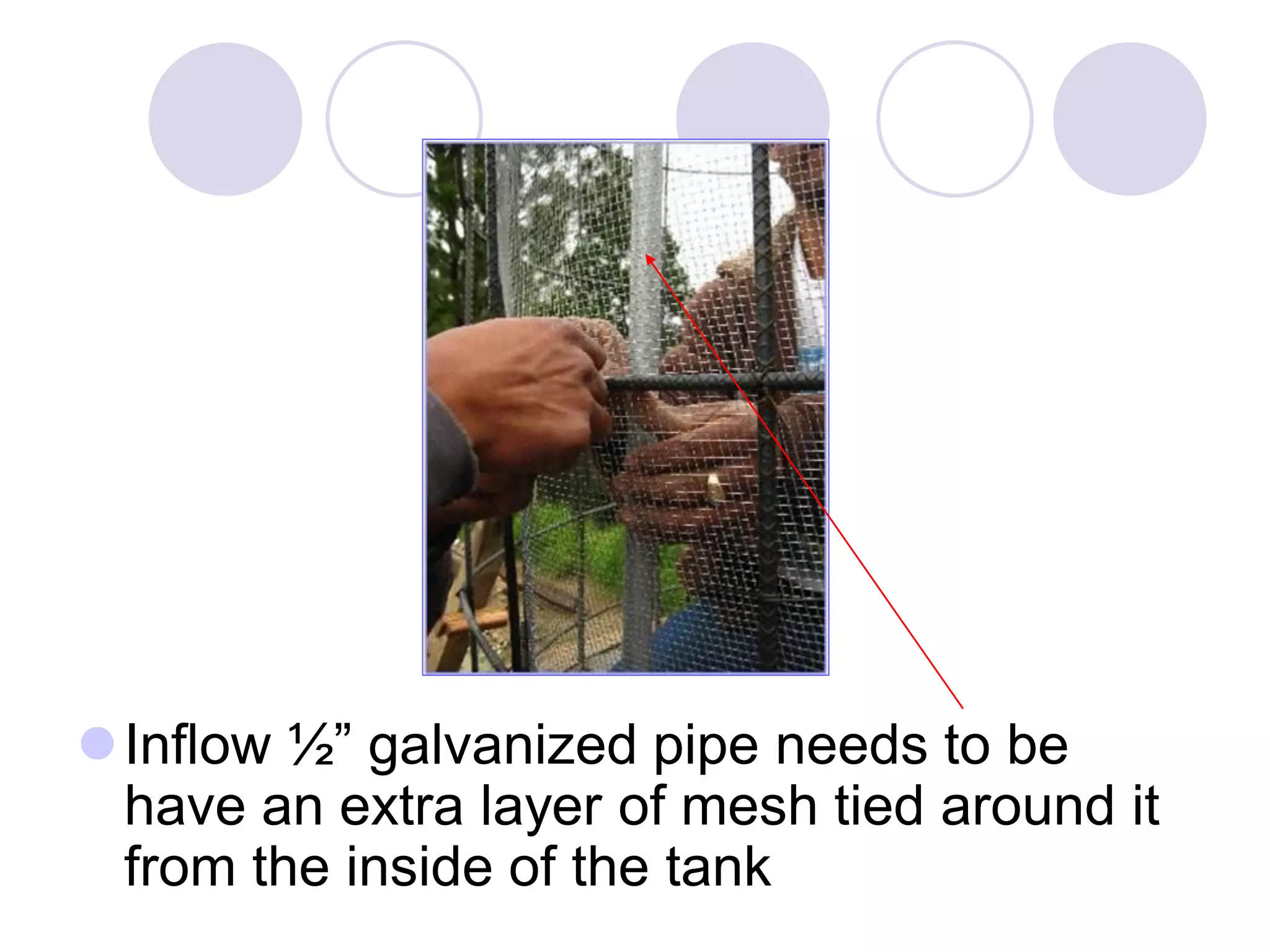

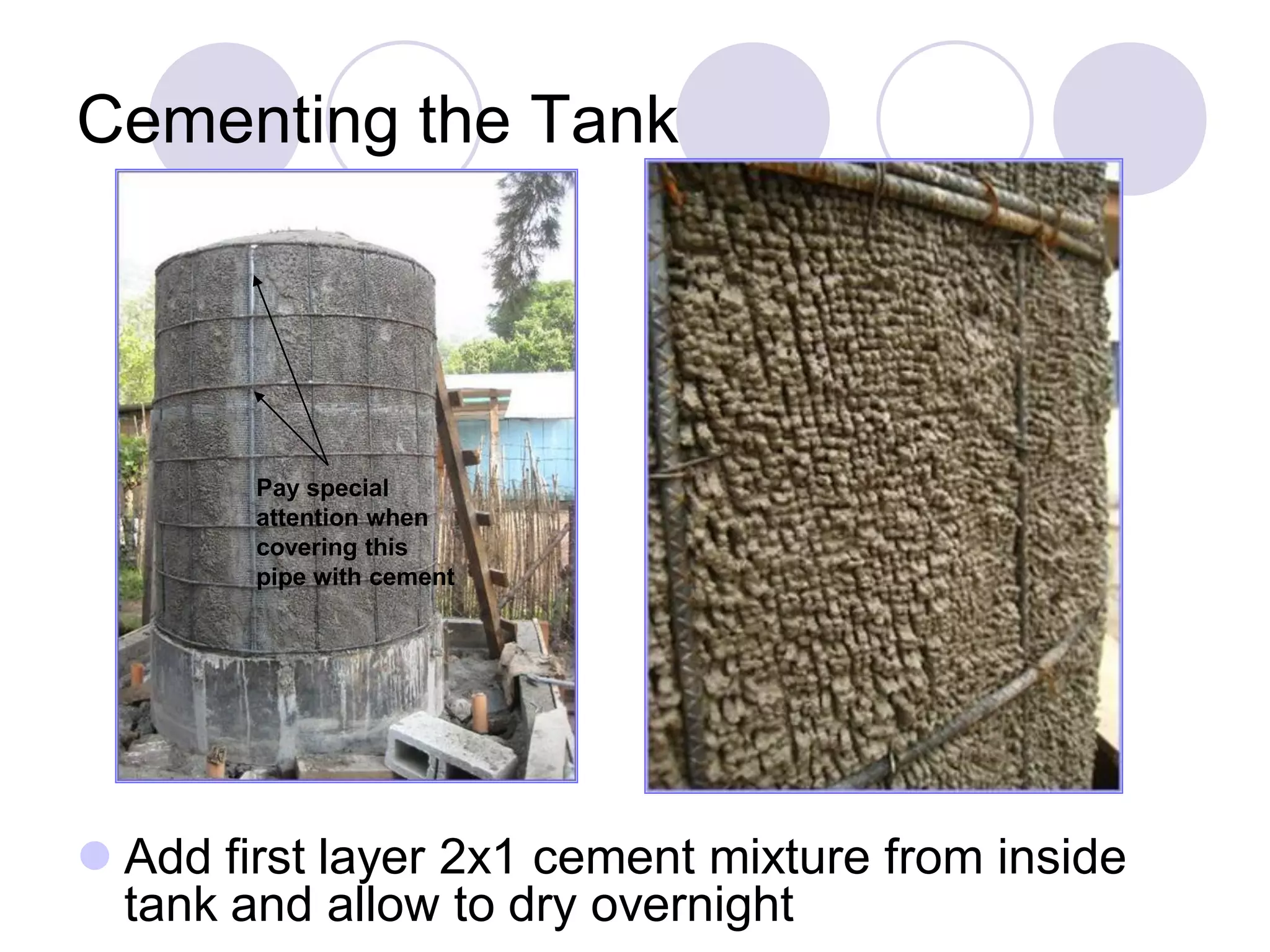

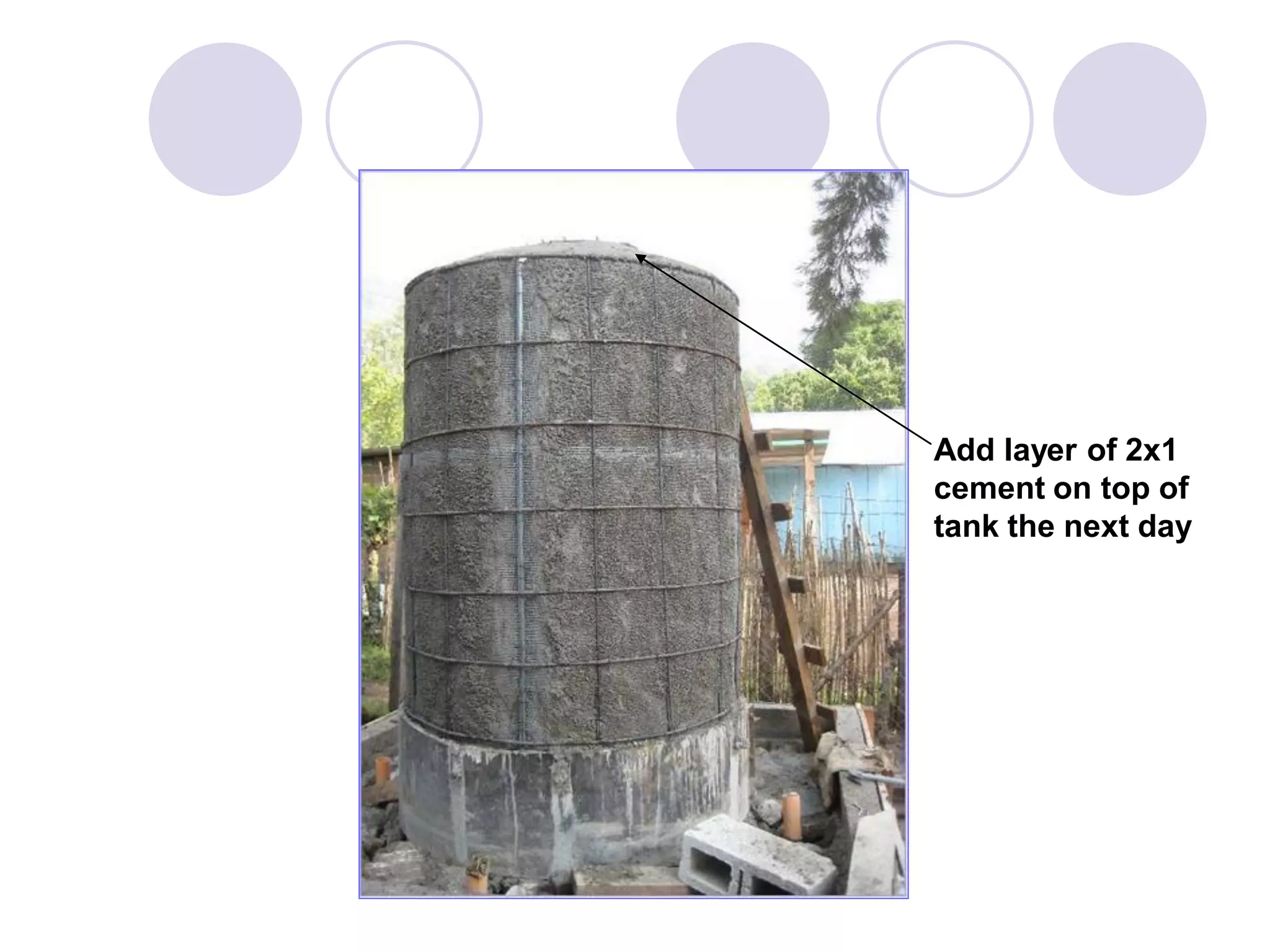

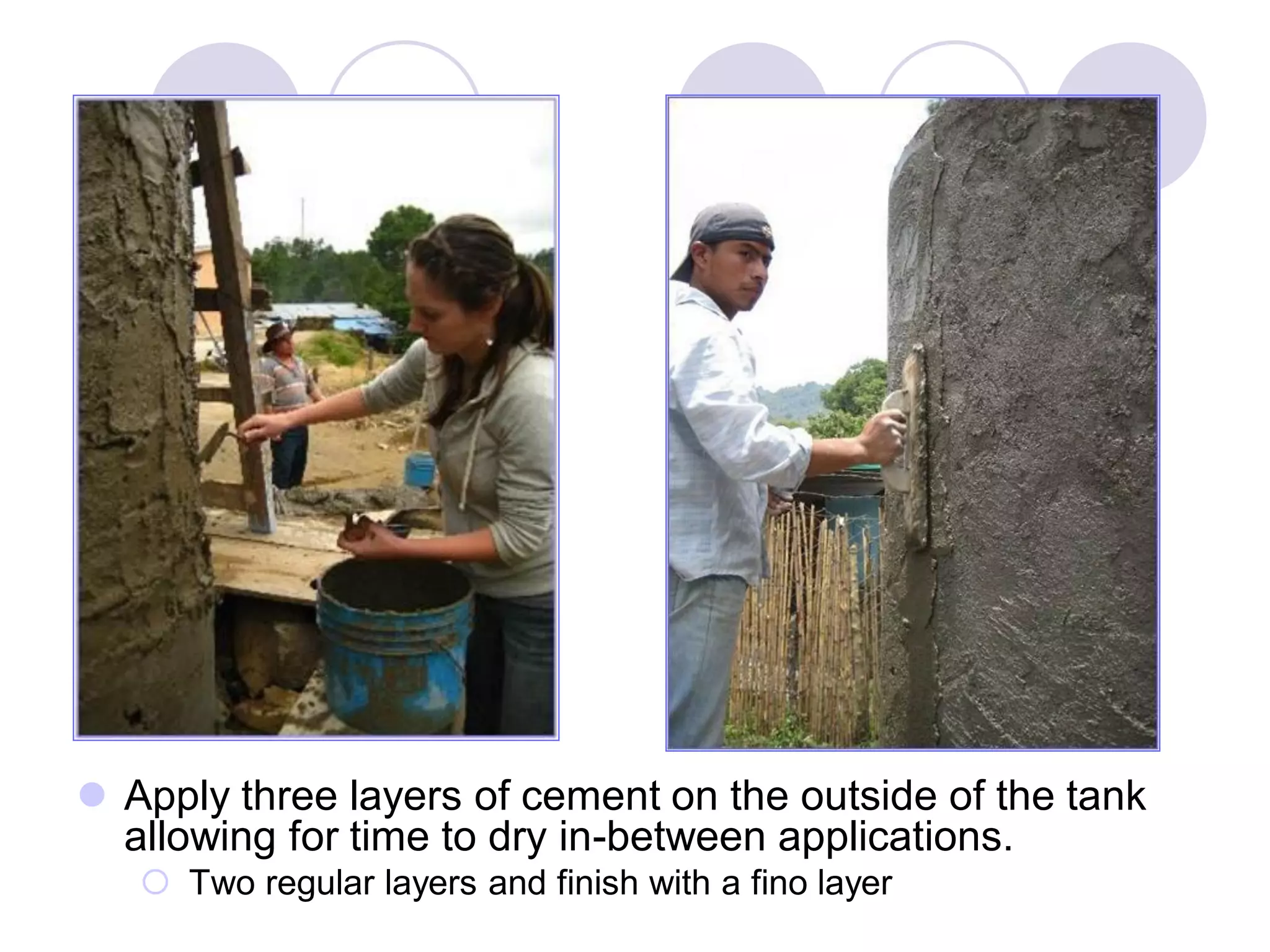

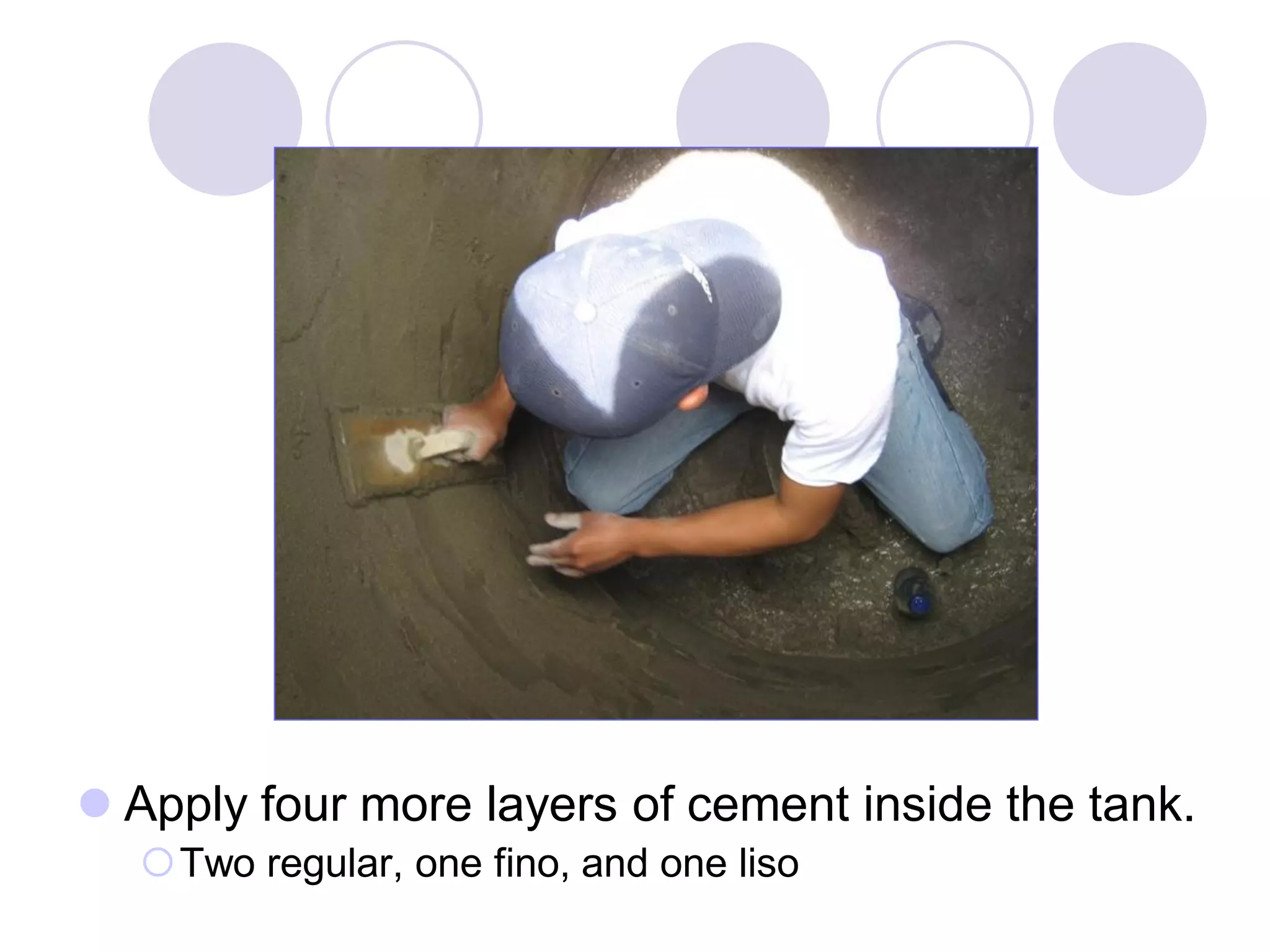

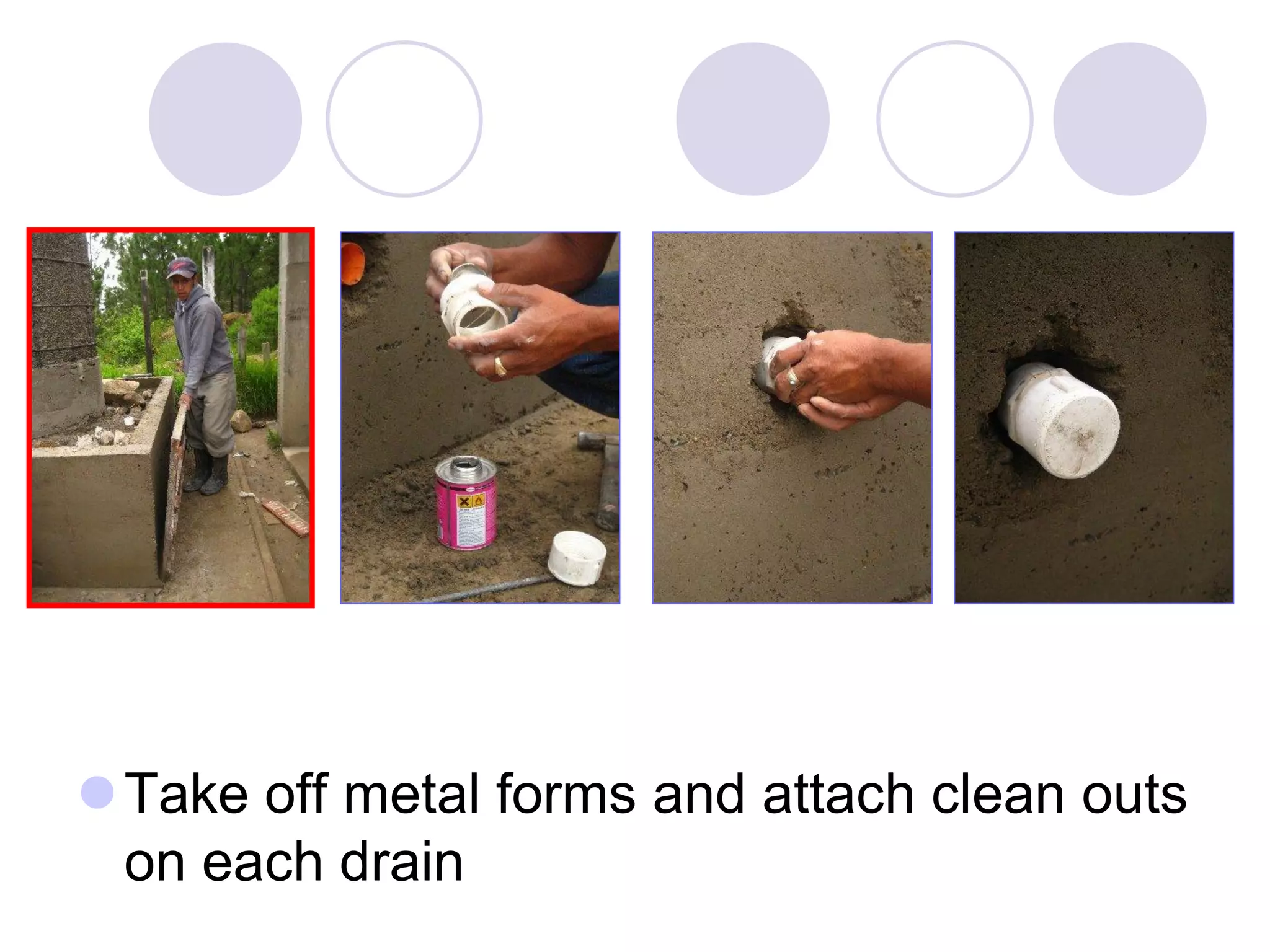

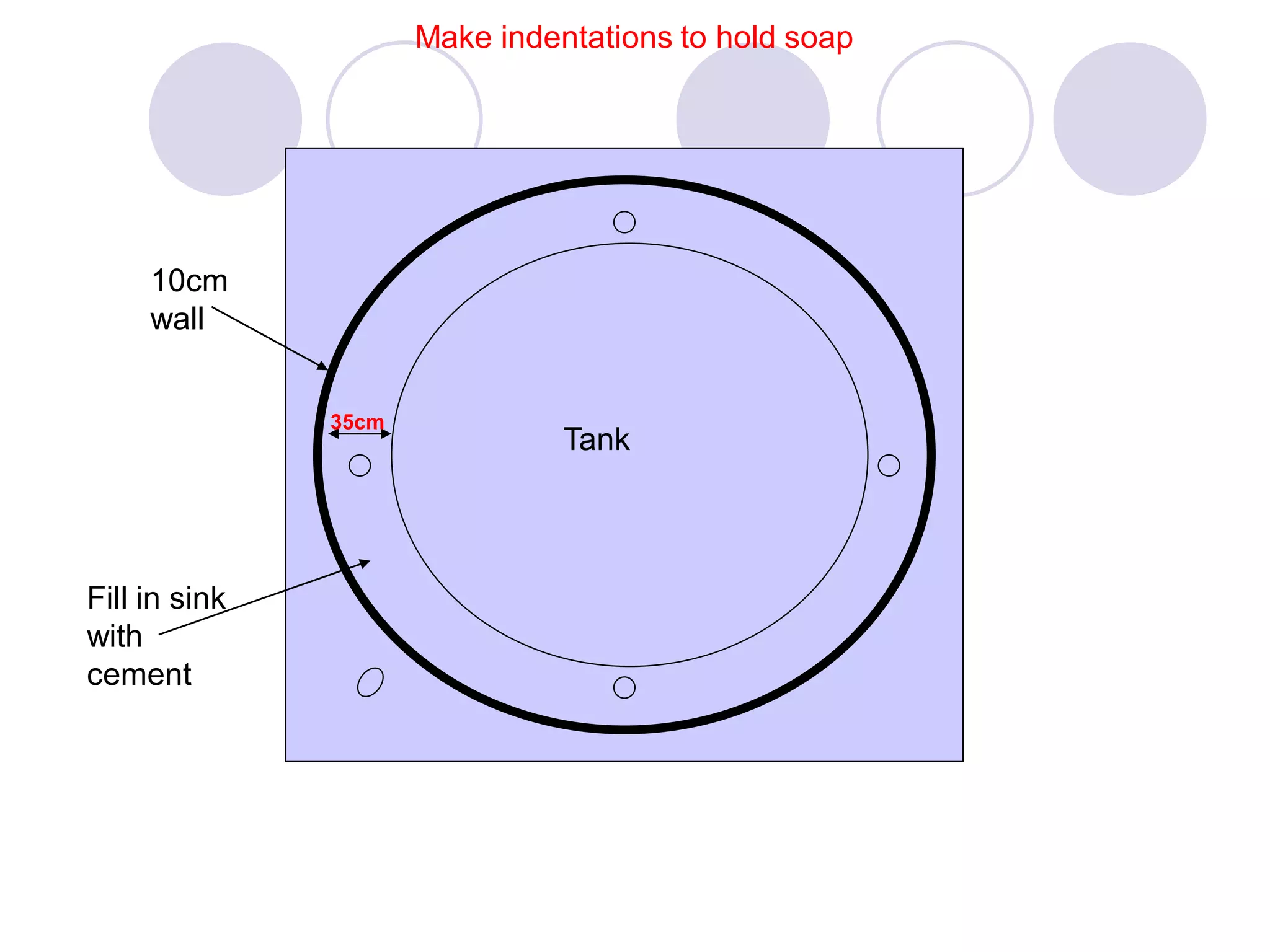

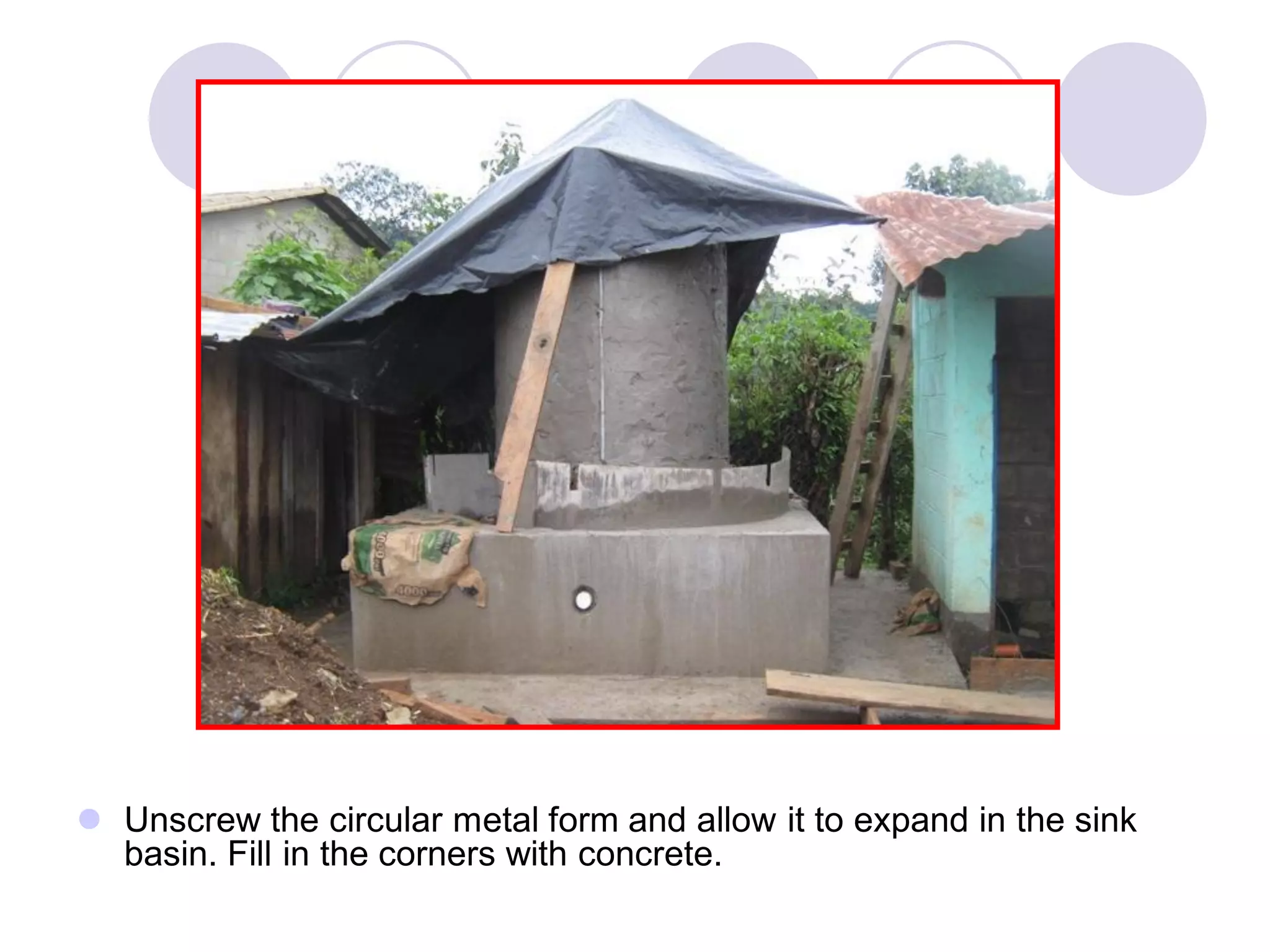

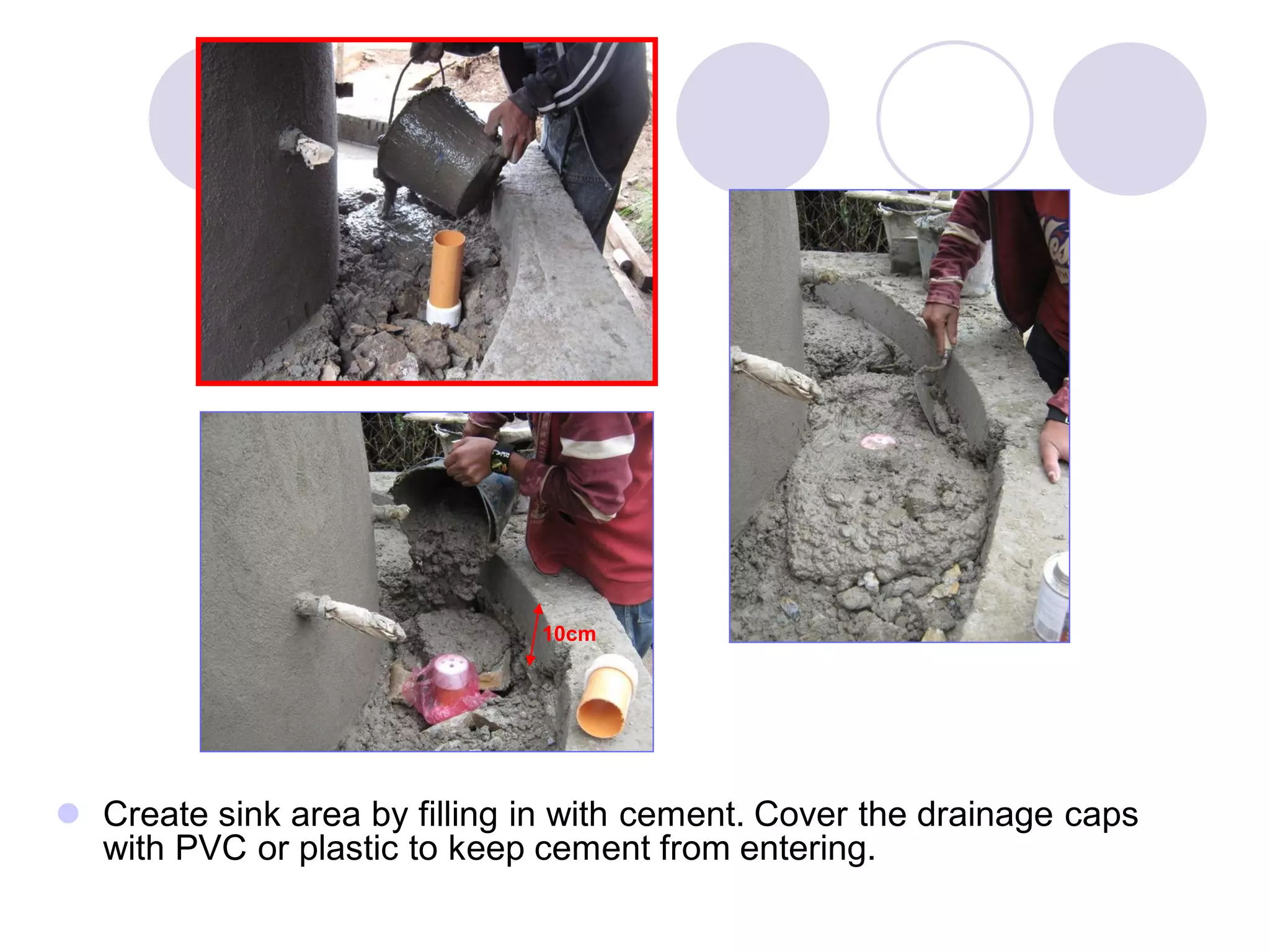

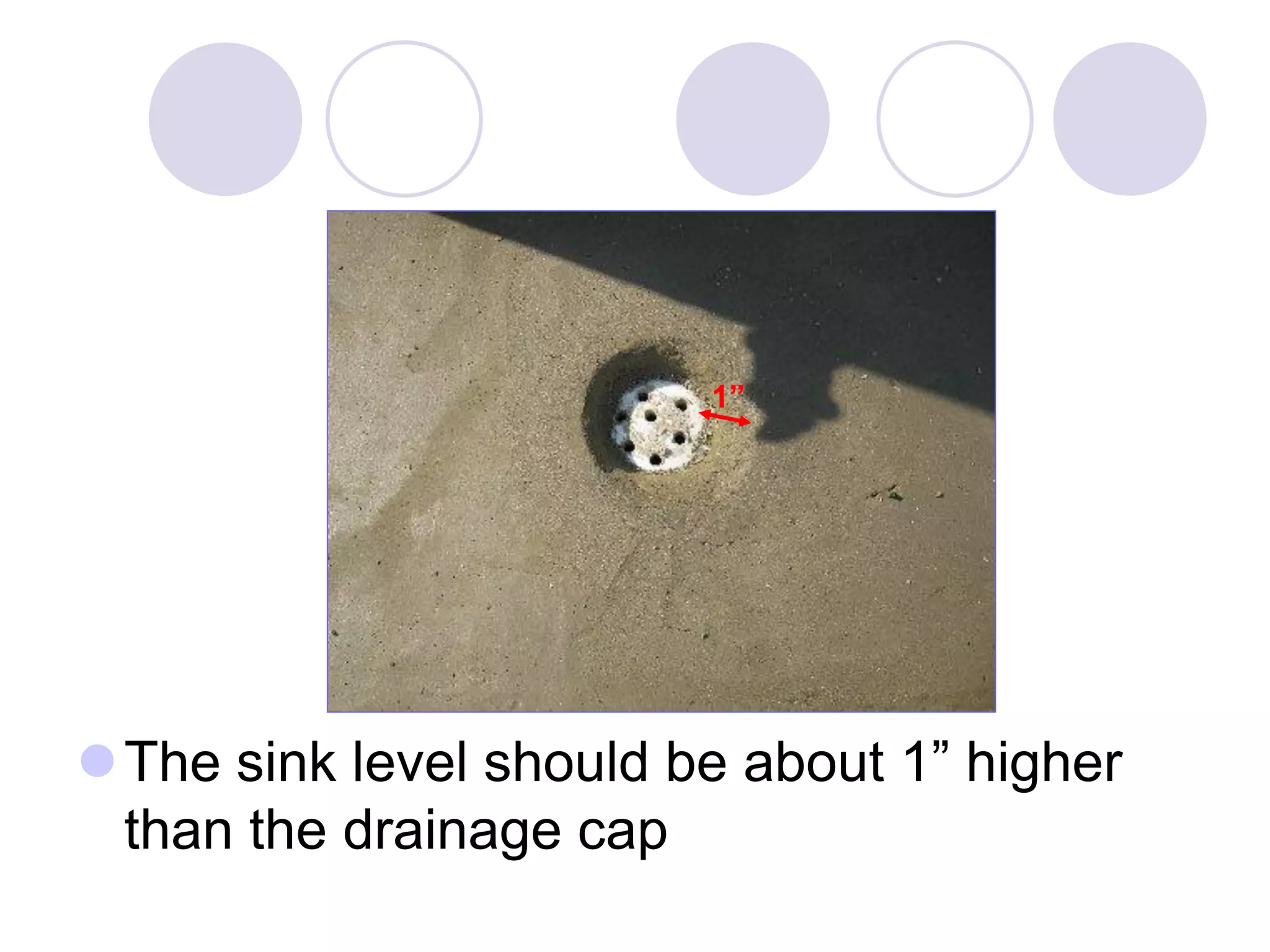

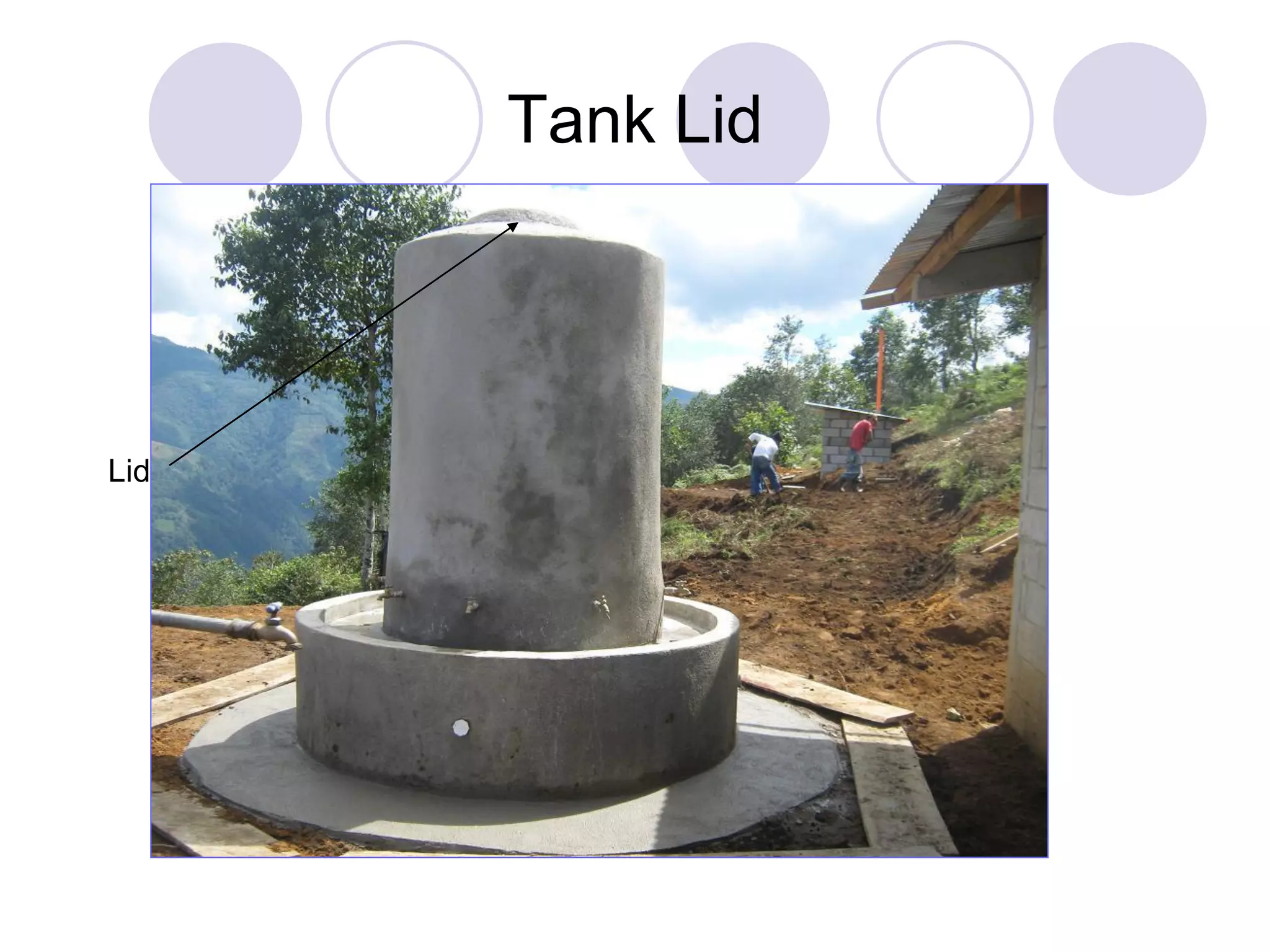

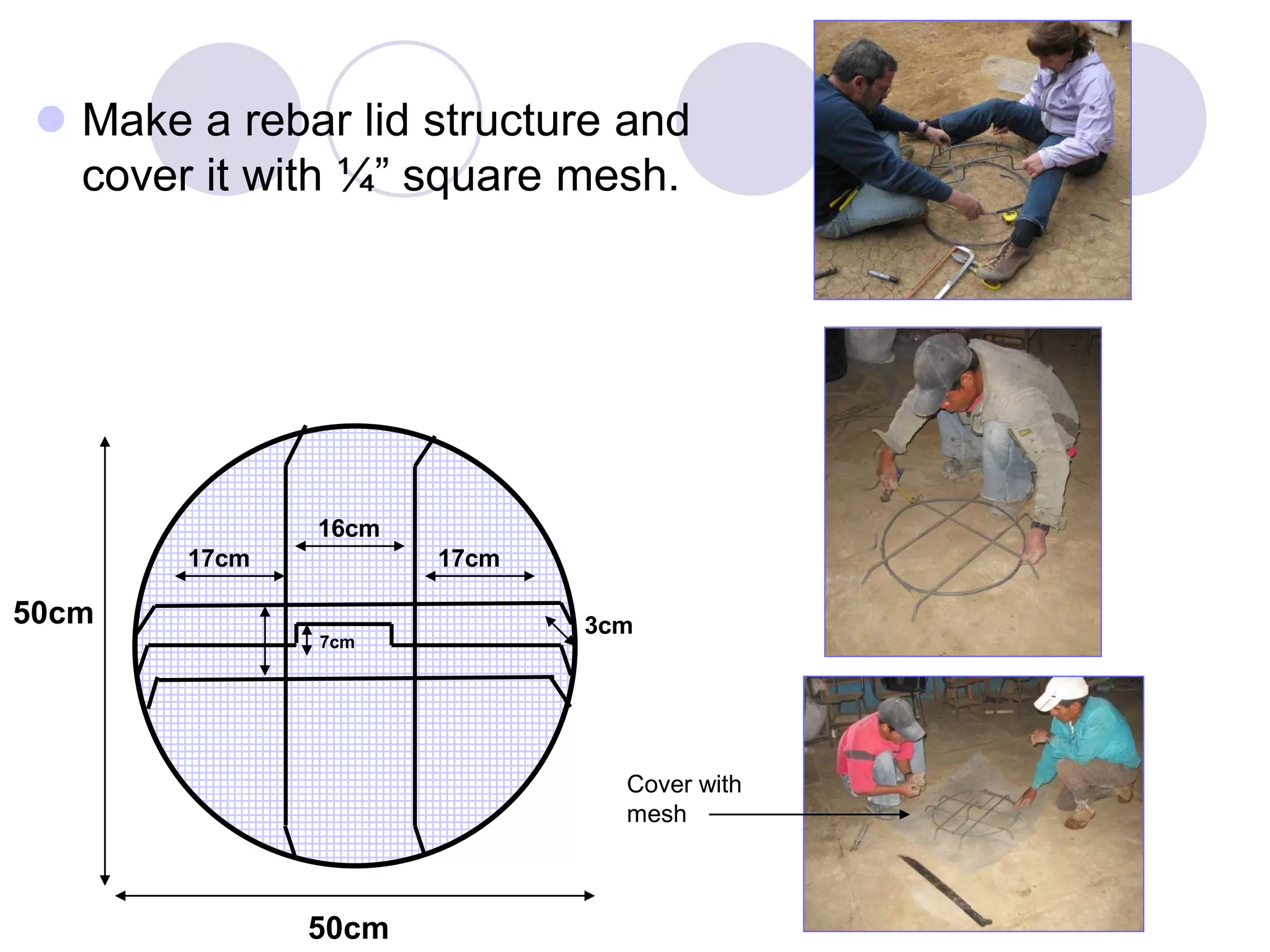

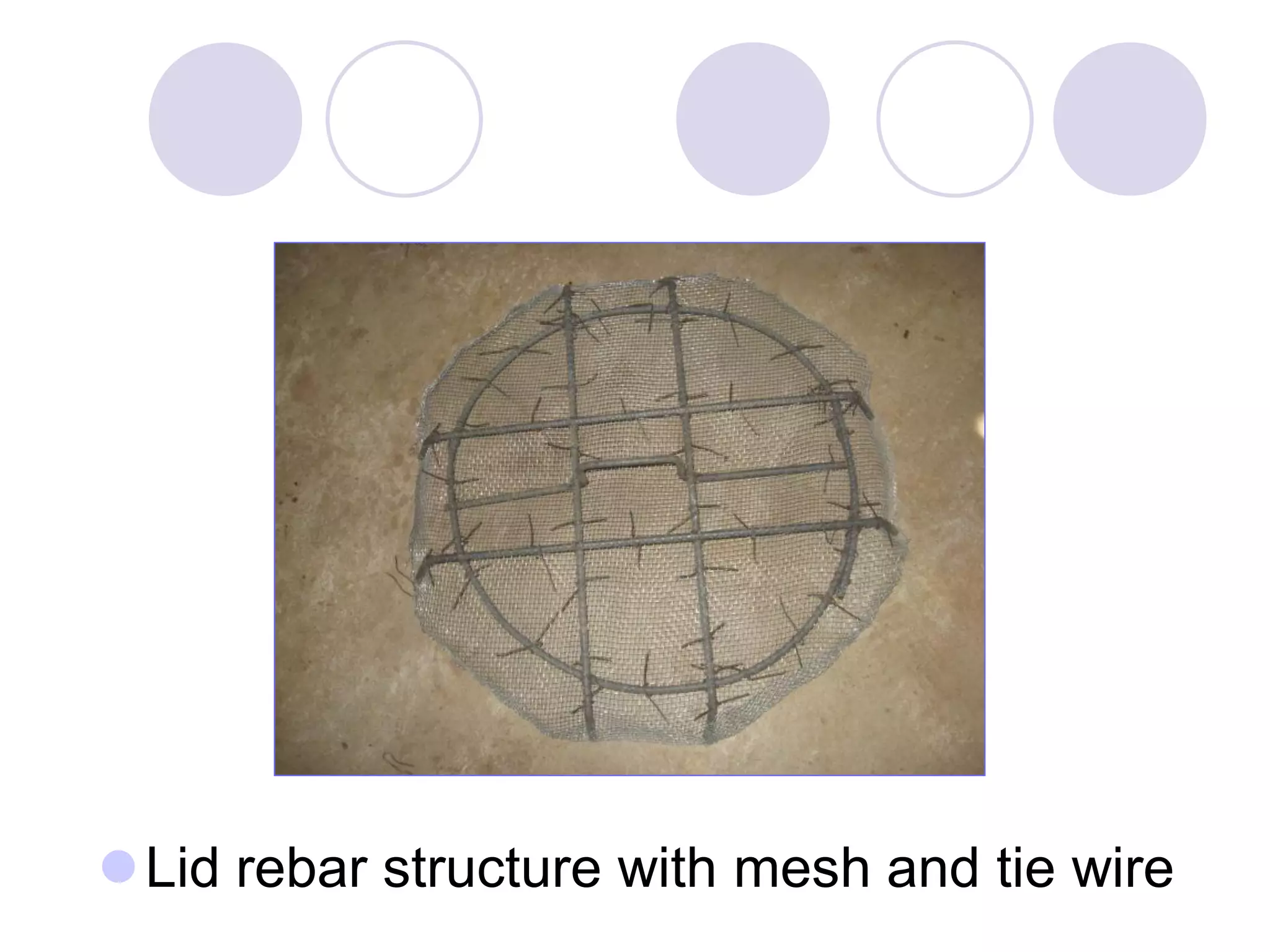

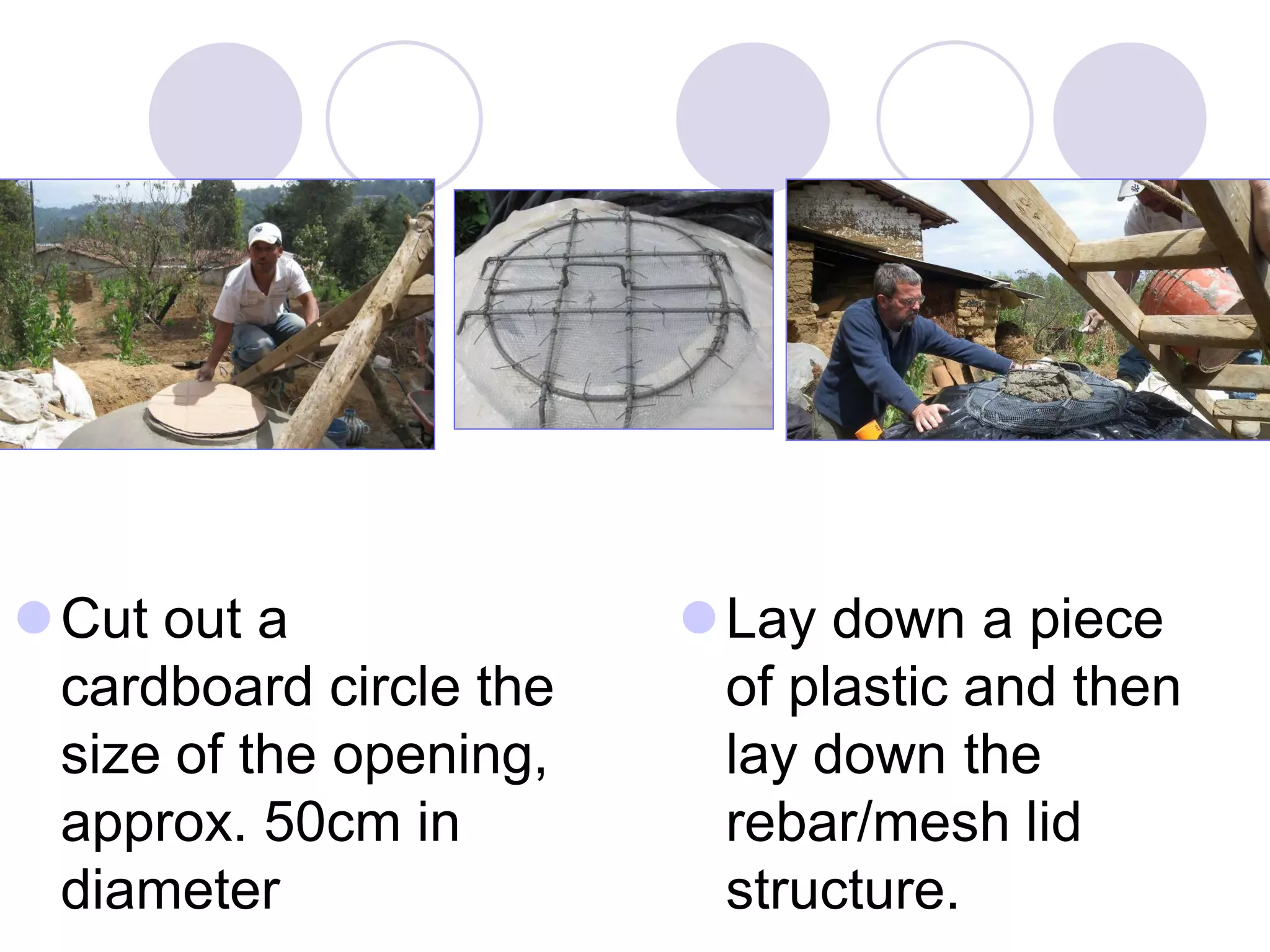

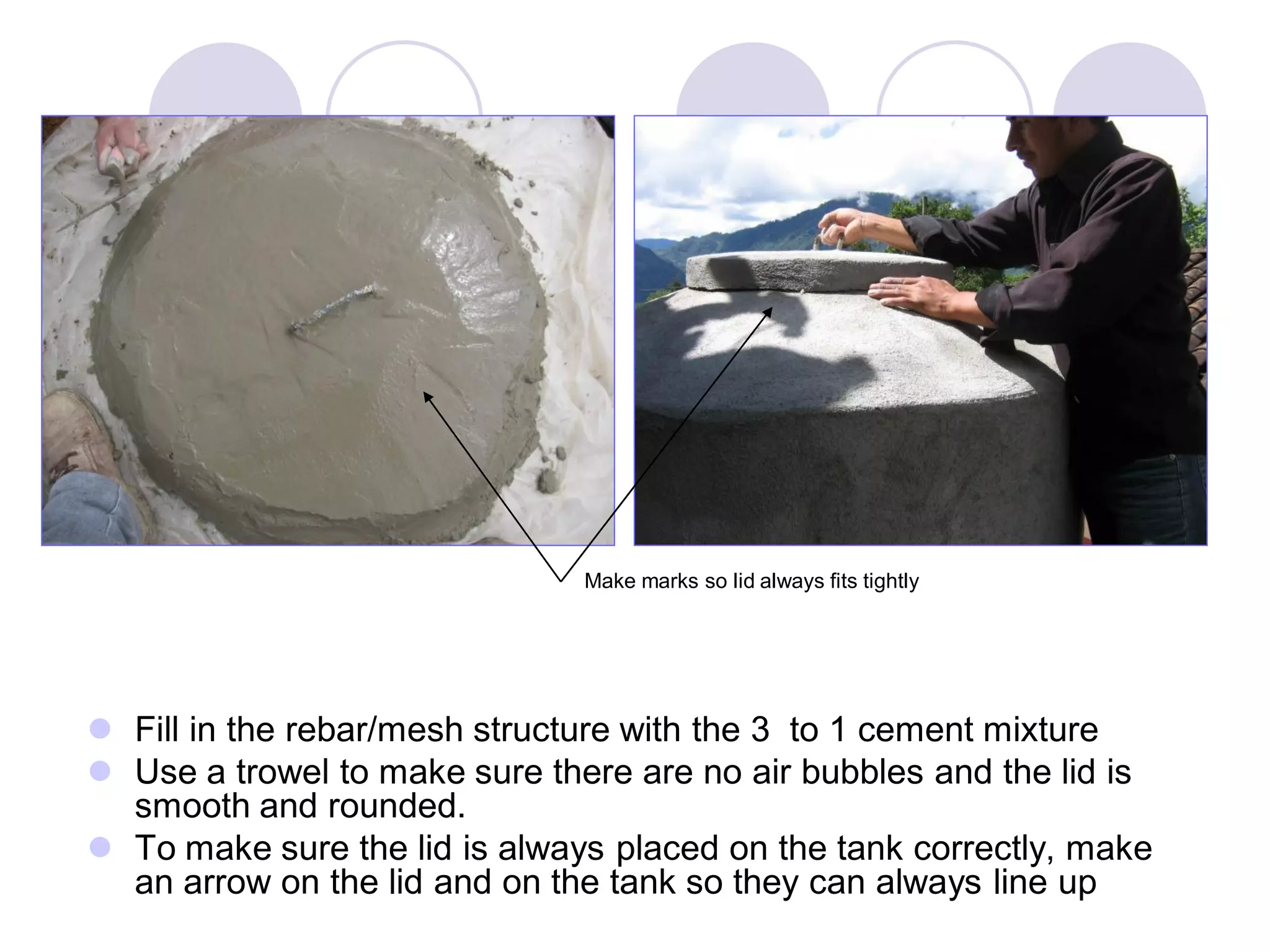

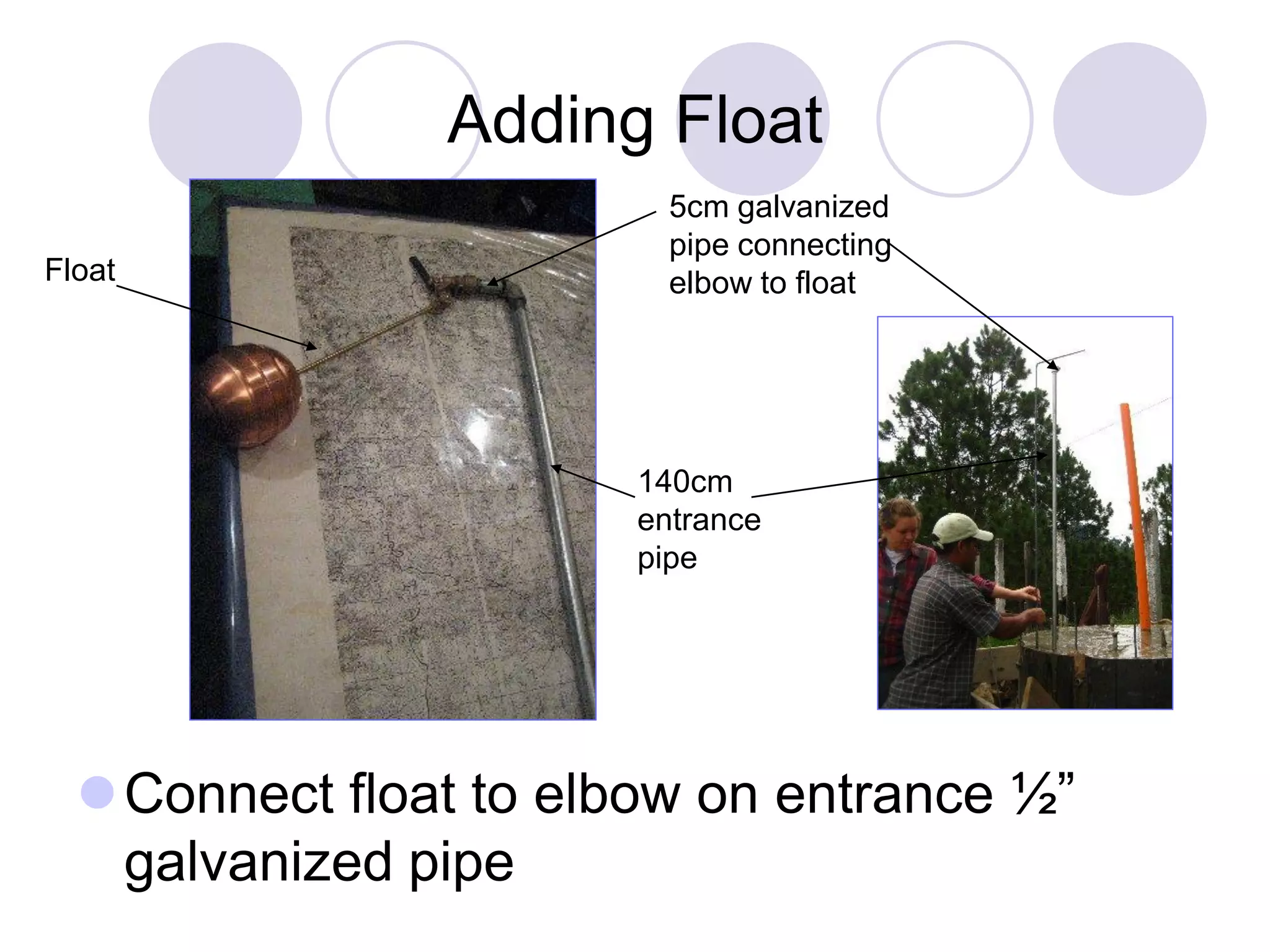

The document provides instructions for building an 8-faucet ferro-cement hand washing station with an integrated 2000L water tank. It details the materials and steps needed to construct the reinforced concrete base, walls and tank. These include laying rebar frames, adding drainage pipes, cementing layers and finishing touches like a lid, faucets and float valve to regulate water levels. The station aims to provide a durable and useful water source for hand washing near homes and facilities.