This document discusses different humidity parameters for HVAC control:

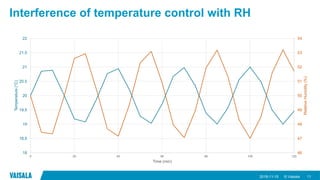

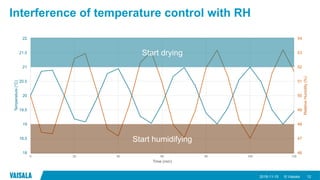

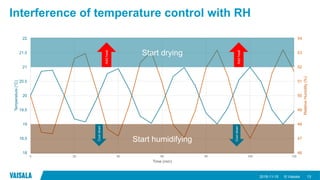

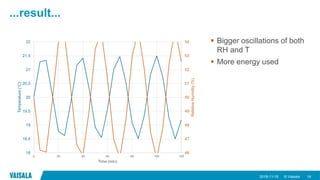

- Relative humidity directly relates to human comfort but can cause oscillations when used with tight temperature control.

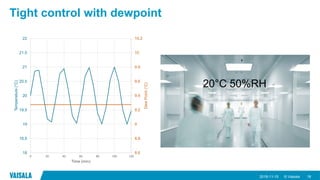

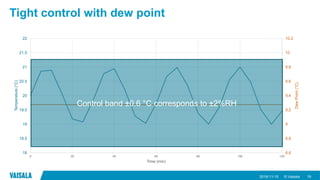

- Dew point is unaffected by temperature changes and allows for tight control but does not directly indicate human comfort.

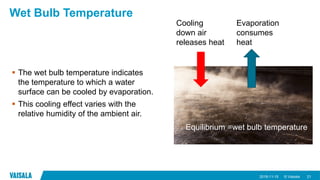

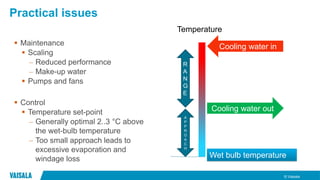

- Wet bulb temperature indicates evaporative cooling potential for applications like cooling towers.

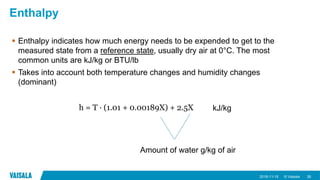

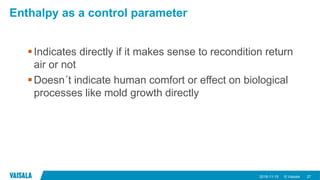

- Enthalpy accounts for temperature and humidity changes, indicating when it is more economical to use outdoor vs return air.

The best parameter depends on the control goal - whether it is human comfort, tight control, or economical air handling. Conversions between parameters can be done through calculations or transmitter outputs.

![© Vaisala

Relative Humidity

The proportion of water

vapor pressure (Pw) to

the maximum vapor

pressure in the given

temperature [Pws(t)]

%RH =

𝑉𝑉𝑉𝑉𝑉𝑉𝑉𝑉𝑉𝑉 𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝

𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 𝑆𝑆 𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣𝑣 𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝 𝑎𝑎𝑎𝑎 𝑡𝑡𝑡𝑡𝑡 𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑𝒑 𝒑𝒑𝒑𝒑 𝒑𝒑𝒑𝒑 𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕𝒕](https://image.slidesharecdn.com/howtochoosetherightparameterforhumidity-181115145800/85/How-to-choose-the-right-parameter-for-humidity-7-320.jpg)

![© Vaisala

Outdoor air economizers

Dampers

2018-11-15[Name] 28

Conditioned airAir handling

unit

Return airExhaust air

Outdoor air

Return air

sensor

Outdoor air

sensor

Is it more economical to use outdoor air or return air?

Δ

H2O

CO2](https://image.slidesharecdn.com/howtochoosetherightparameterforhumidity-181115145800/85/How-to-choose-the-right-parameter-for-humidity-28-320.jpg)

![© Vaisala

The Economizer logic

2018-11-15[Name] 29

1: Return air is 76°F/24.4°C,

50%RH, enthalpy is 28.7 BTU/lb

2: Cold but wet outdoor air: 72°F/

22.2°C, 90%RH, enthalpy is 33.9

BTU/lb should not be used for

cooling

3: Hot but dry outdoor air: 85°F/

29.4°C, 15.4%RH, enthalpy is 24.7

BTU/lb. Should be used instead of

return air](https://image.slidesharecdn.com/howtochoosetherightparameterforhumidity-181115145800/85/How-to-choose-the-right-parameter-for-humidity-29-320.jpg)