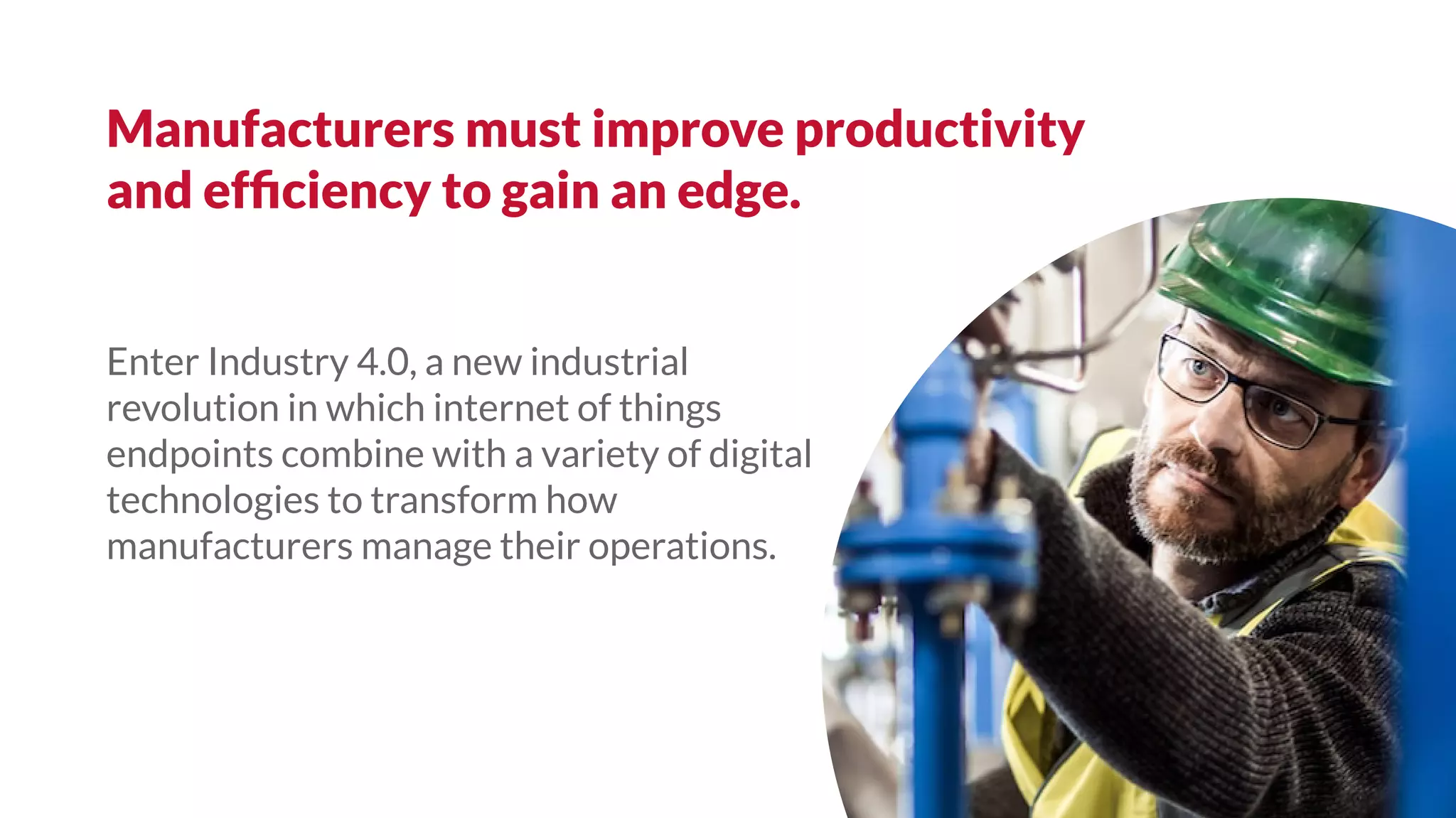

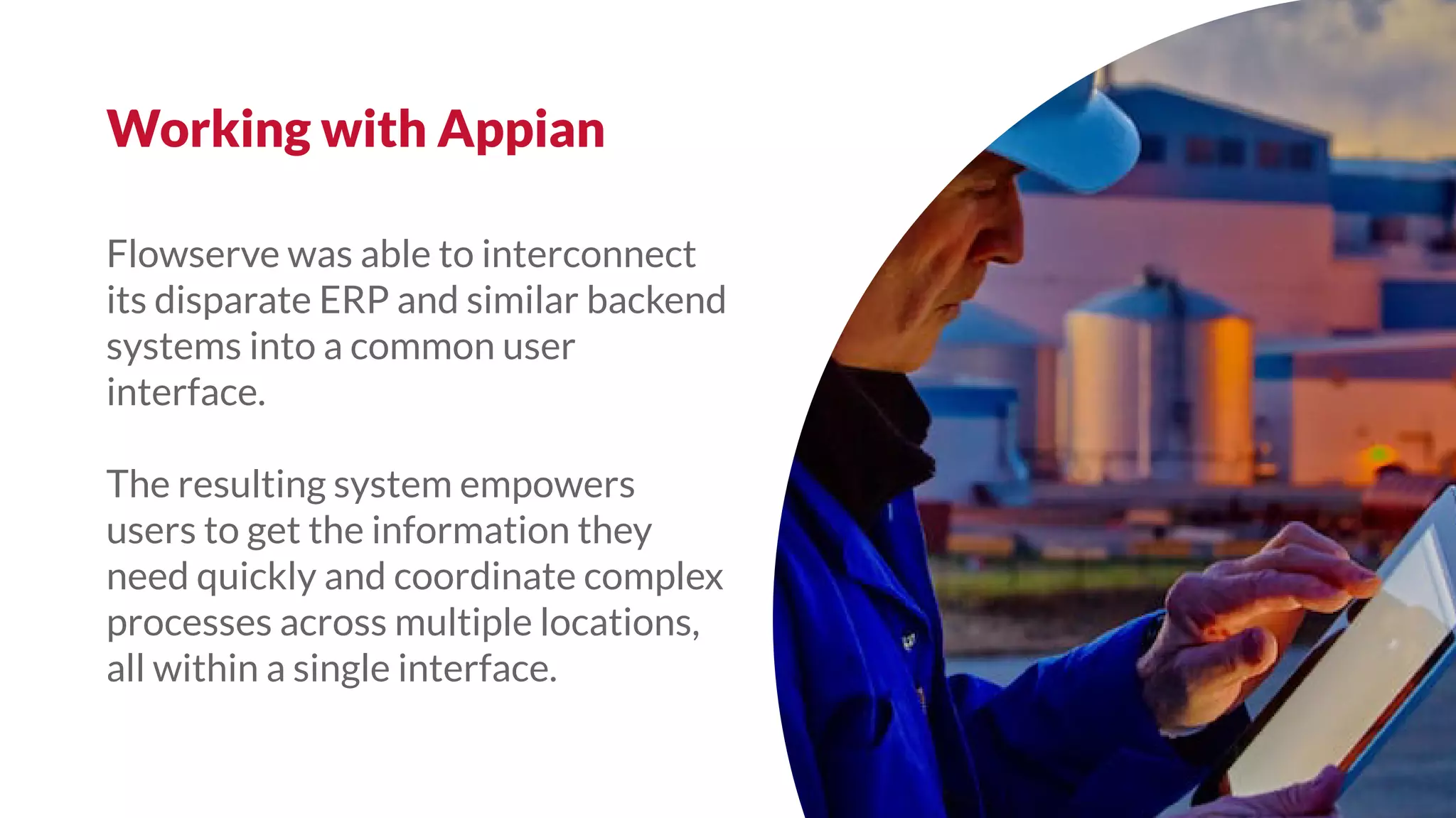

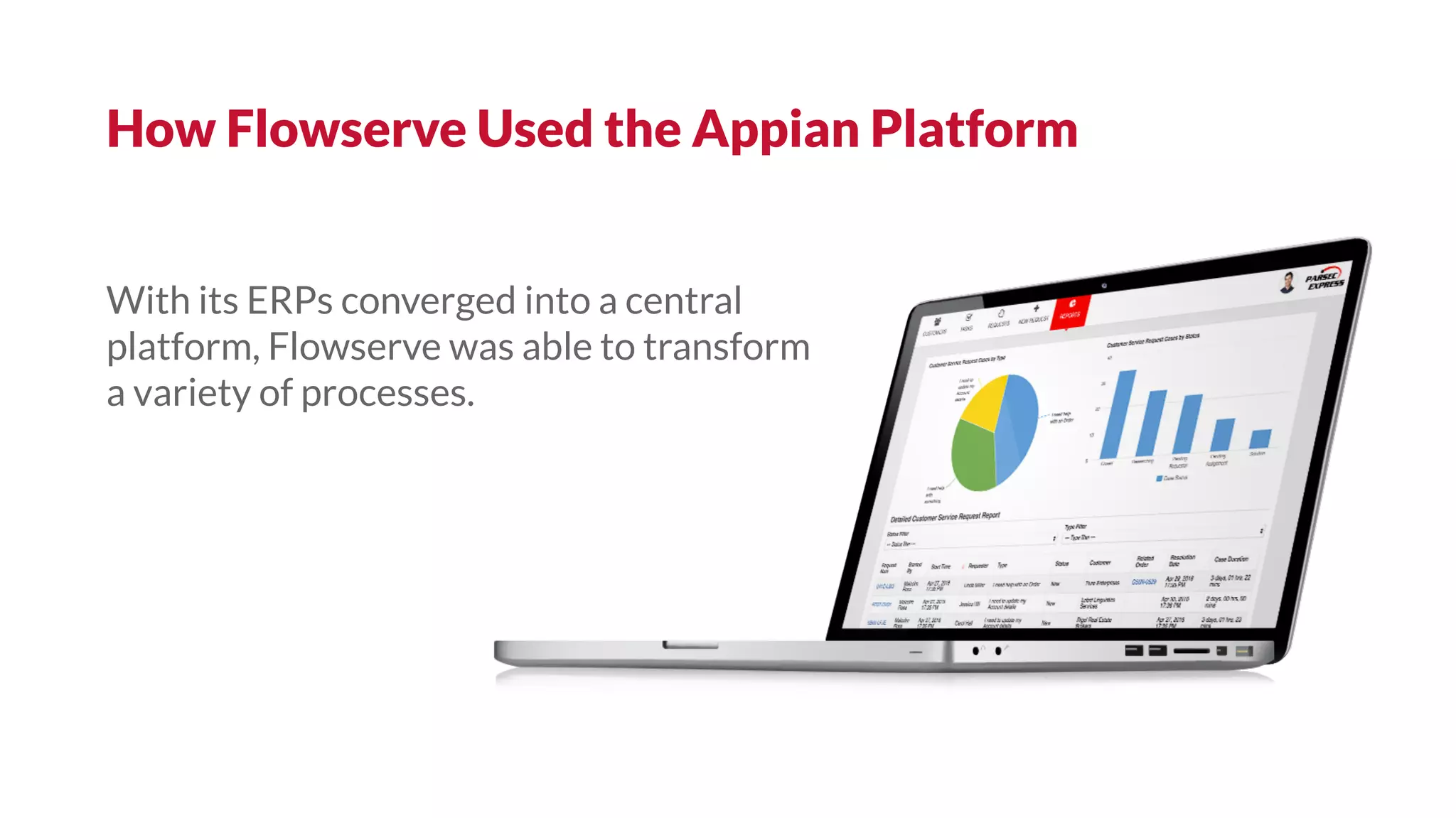

Flowserve exemplifies how manufacturers can enhance efficiency through interconnected processes amid challenging global economic conditions. By utilizing Appian's digital transformation platform, Flowserve centralized its diverse Enterprise Resource Planning (ERP) systems, streamlining operations and significantly improving dispute resolution and aftermarket support. This transformation led to reduced average dispute resolution times and facilitated a cohesive customer experience across its global response centers.