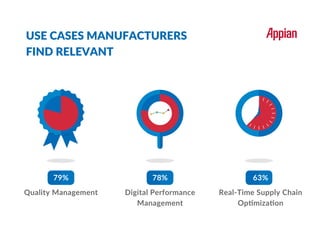

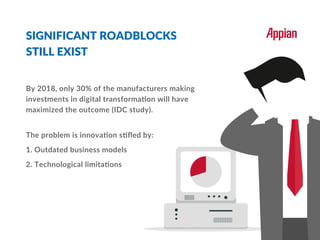

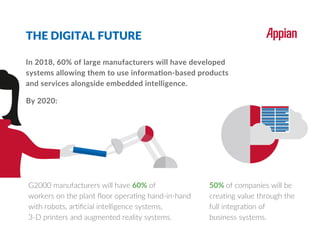

A McKinsey study shows that 60% of manufacturers are optimistic about digitization, with key use cases in quality management and supply chain optimization. However, only 30% of those investing in digital transformation will maximize outcomes due to outdated business models and technological limitations. By 2020, significant advancements are expected, including widespread integration of AI and low-code platforms to enhance operational efficiency.