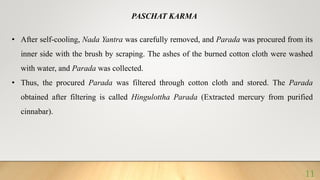

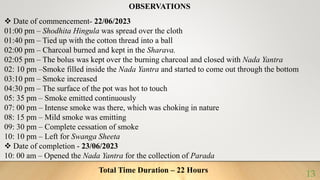

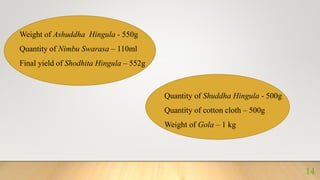

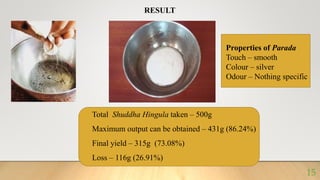

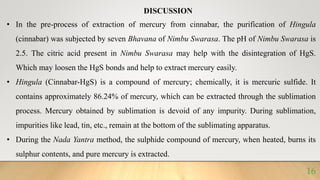

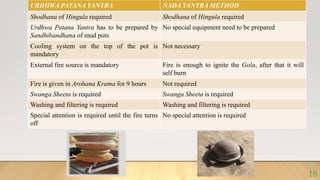

The document discusses the extraction of parada from shodhita hingula using the nada yantra method, aiming to provide an efficient alternative to traditional purification processes in Ayurveda. The study reports a successful extraction of 315 grams of parada with a yield of 73.08%, highlighting the importance of purification and preparation methods employed. The findings suggest the nada yantra method can benefit Ayurvedic pharmaceutical industries by improving extraction efficiency and reducing losses.

![1. Bhatta K. R., Siddha Bhaishajya Manimala, Bhatta R. K., Hindi commentary, Krishna Das Academy, Varanasi, 199,

Page no 356.

2. Sadanand Sharma, Rasatarangini, with Prasadanee Vyakhya of Haridutta Shastri and Hindi commentary by

Ayurvedacharya Pandit Dharmananda Shastri. Eleventh Edition: 1979, Reprint: 2009, Motilal Banarasidas, Delhi, Page

no 202.

3. Rakesh et al., Extraction Of Parad From Hingula, A Traditional Ayurvedic Method, World Journal of Pharmaceutical

Research, Volume 7, Issue 05 Page no 1026-1032. [cited on 08/11/2023]

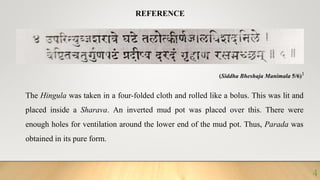

REFERENCE

21](https://image.slidesharecdn.com/cluster-231225050827-f6e75f54/85/Hingulotha-Parada-extraction-by-Nadayantra-pptx-21-320.jpg)