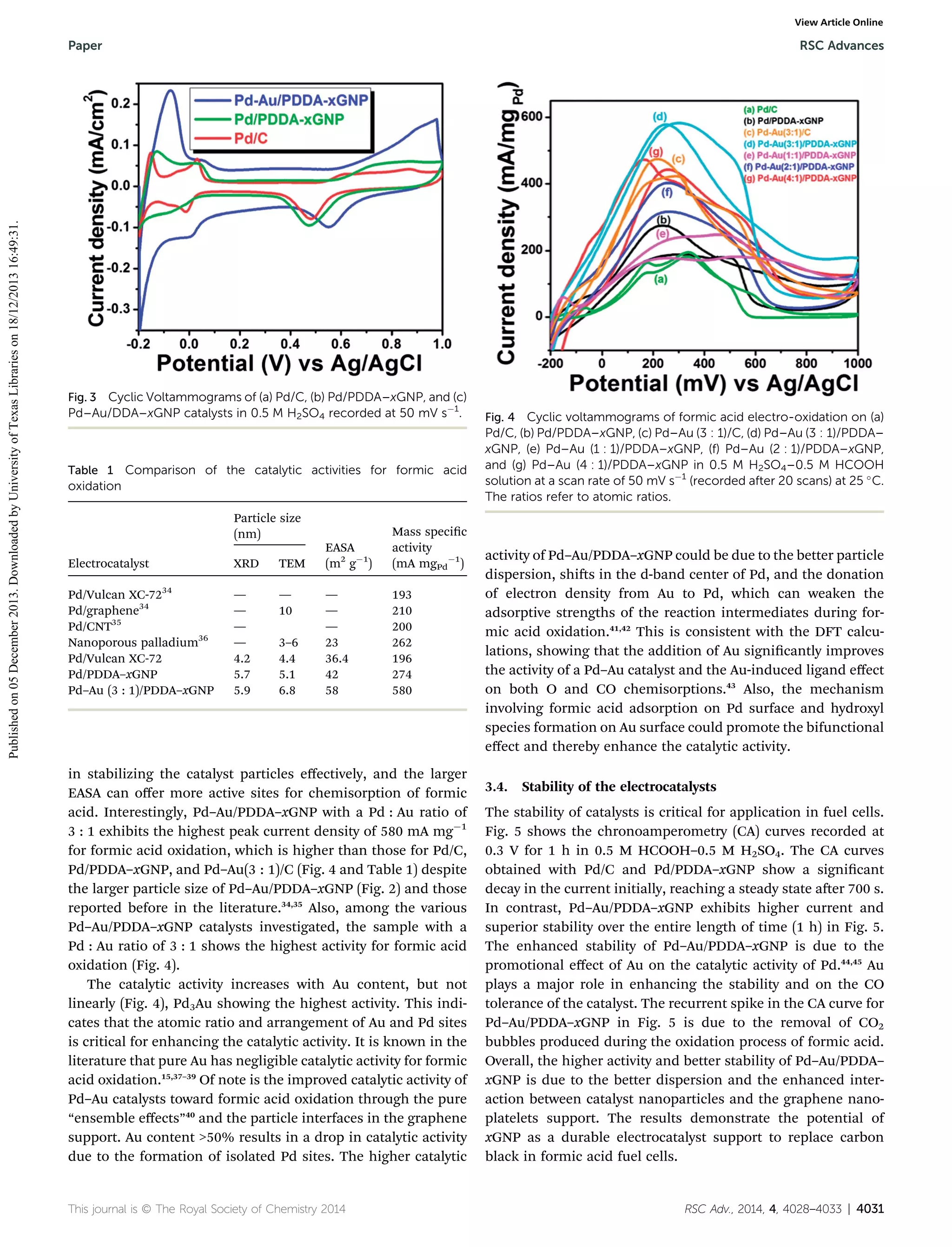

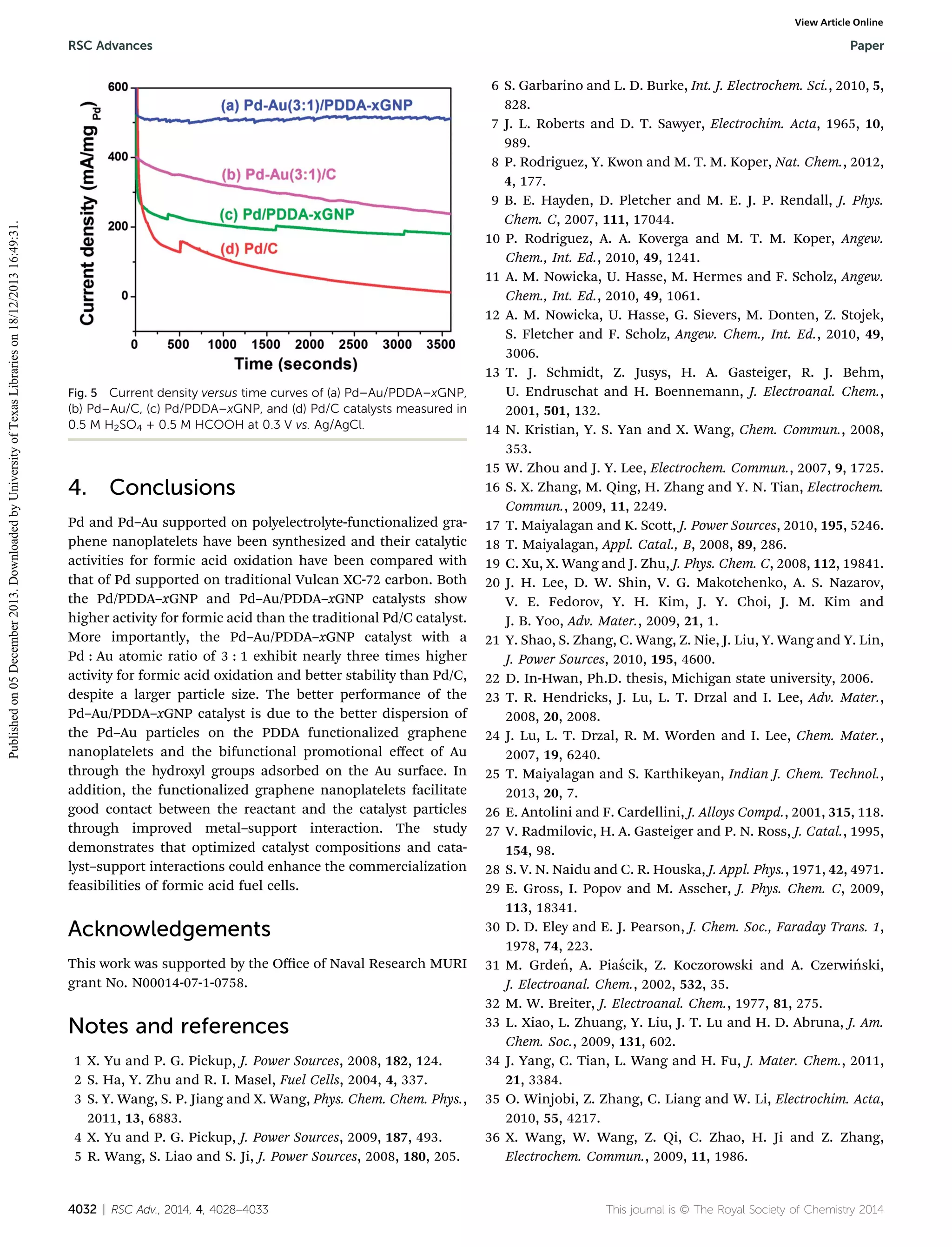

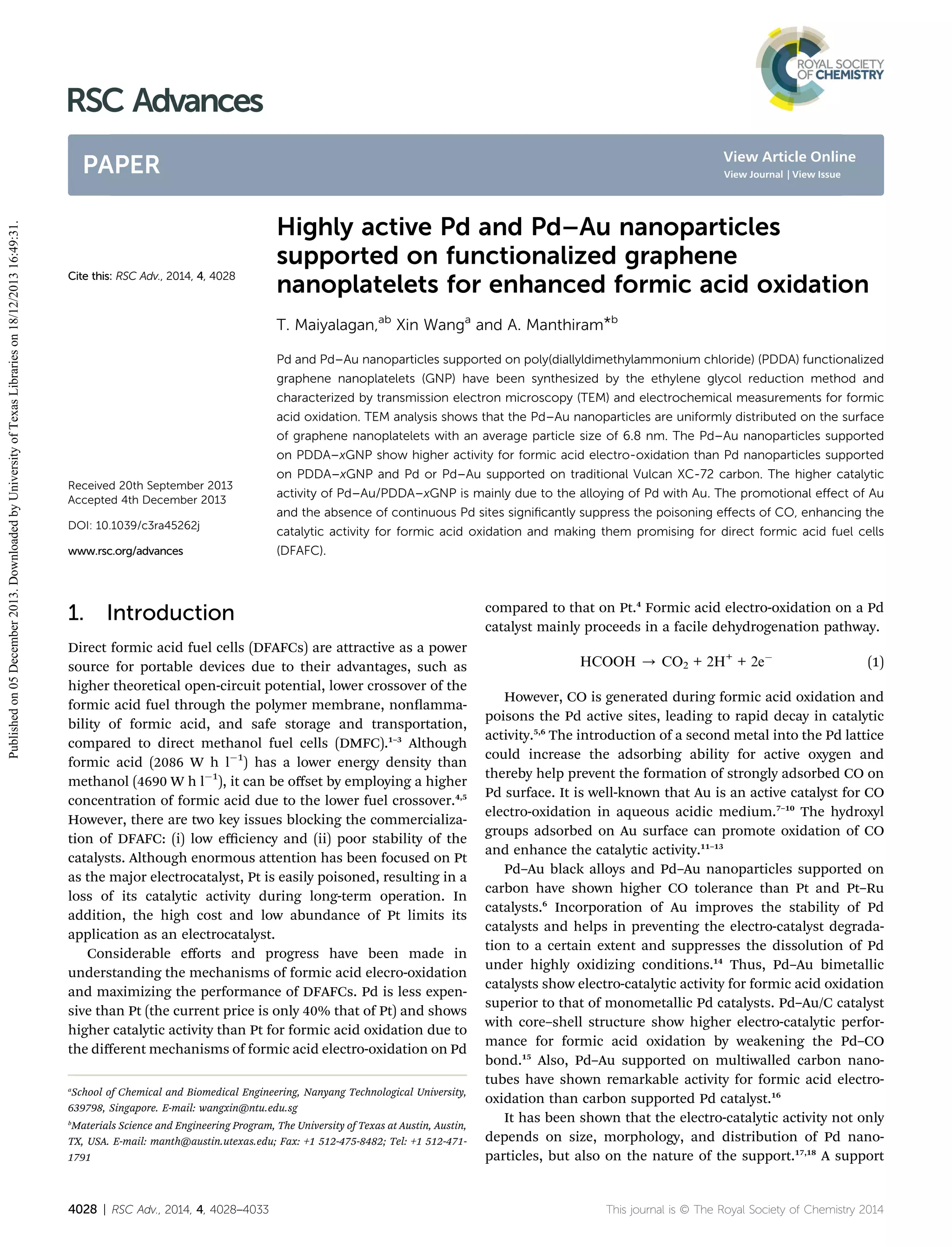

The study focuses on the synthesis and characterization of highly active palladium (Pd) and palladium-gold (Pd-Au) nanoparticles supported on functionalized graphene nanoplatelets for enhanced formic acid oxidation. Results indicate that the Pd-Au nanoparticles demonstrate superior catalytic activity for formic acid electro-oxidation compared to conventional Pd catalysts, attributed primarily to the alloying effect of Au, which mitigates catalyst poisoning. The research highlights the potential of these catalysts in direct formic acid fuel cells, emphasizing their advantages over traditional systems.

![View Article Online

Published on 05 December 2013. Downloaded by University of Texas Libraries on 18/12/2013 16:49:31.

Paper

RSC Advances

with the ability to control, stabilize, and disperse the metal

nanoparticles can greatly enhance the performance. In particular, there has been increased interest in graphene nanoplatelets (GNPs). They have been explored as durable catalyst

supports for fuel cells due to the following distinct characteristics: (1) superior conductivity and (2) strong corrosion resistance.19–22 We demonstrate here, for the rst time, that Pd–Au

nanoparticles supported on graphene exhibit enhanced electrocatalytic activity and stability for formic acid oxidation

compared to Pd supported on carbon (Pd/C).

2.

Experimental

2.1. Functionalization of graphene nanoplatelets by PDDA

(PDDA–xGNP)

All the chemicals are of analytical grade and were used as

received. The graphene nanoplatelets (xGNP) (purity $ 99.5%)

were obtained commercially from XG Sciences (USA).23,24 These

nanoplatelets were small stacks of graphene sheets, about 5–10

nm in thickness with a specic surface area of 112 m2 gÀ1.25

xGNP was functionalized with a long-chain positively charged

polyelectrolyte, poly (diallyldimethylammonium chloride)

(PDDA) (MW ¼ 200k to 350k, Sigma-Aldrich). PDDA can be

easily adsorbed onto the hydrophobic surface of xGNP via the

p–p interaction between the unsaturated C]C contaminant in

the PDDA chains22,25 and graphene planes of xGNP. Typically,

300 mg of xGNPs was dispersed in 500 mL of 0.5 wt% PDDA

aqueous solution and ultrasonicated for 3 h, which yielded a

stable dispersion of xGNP. Then, the dispersed solution of

xGNP was stirred for 24 h. Aer that, 2.5 g of KNO3 was added to

increase the binding between PDDA and xGNP surface, resulting in a highly functionalized xGNP with PDDA.21 The solution

was stirred for another 24 h, ltered, and washed with ultrapure

deionized water (18.2 MU cm, Mill-Q Corp.) to remove the free

polyelectrolyte and then dried for 3 h at 90 C in vacuum, which

is hereaer denoted as PDDA–xGNP.

2.2. Synthesis of Pd–Au/PDDA–xGNP catalysts

First, 0.9433 g of sodium citrate was dissolved in 165 mL of

water–ethylene glycol mixture solution (volume/volume ¼ 1 : 1),

and then 160 mg of functionalized PDDA–xGNP was transferred

into the above solution to obtain the sodium citrate suspension,

which was stirred and ultrasonically mixed for 2 h. 44.5 mg of

K2PdCl4 and 44.5 mg of HAuCl4$3H2O (aqueous solution containing 1 g per 100 mL) were dissolved in another 40 mL of

water–ethylene glycol solution. The sodium citrate suspension

was reuxed at 170 C in argon atmosphere for 5 min. The

catalyst precursor solution was then added drop-wise into the

heated sodium citrate suspension and the solution was diluted

by adding 40 mL of water–ethylene glycol solution (volume/

volume ¼ 1 : 1) and continued to be heated for another 2 h. The

catalyst thus obtained with 20 wt% metal loading was then

ltered, washed with water and ethanol, dried at 60 C for 12 h,

and then reduced in hydrogen at 150 C for 2 h. The as

synthesized catalyst is hereaer denoted as Pd–Au/PDDA–

xGNP. The Pd supported on PDDA–xGNP sample with 20 wt%

This journal is © The Royal Society of Chemistry 2014

Pd was prepared by the same process, but without including the

Au precursor in the synthesis, and this sample is hereaer

denoted as Pd/PDDA–xGNP. Commercial Pd/C catalyst was

obtained from Johnson Matthey.

2.3. Preparation of working electrode

The Glassy Carbon (GC) electrode was polished before each

experiment to a mirror nish with 0.05 mm alumina suspensions and rinsed thoroughly with double distilled water. The

electrode was dried in a high purity nitrogen stream. The

catalyst ink suspensions were prepared by mixing the required

amount of catalyst in 0.5% Naon solution. The mixture was

sonicated for 30 min in an ultrasonication bath and 7 mL of the

resulting catalyst ink was cast onto the surface of the GC electrode (5 mm diameter, 0.196 cm2). The modied electrode was

allowed to dry at 80 C for 5 min to obtain a uniform catalyst

lm. All electrochemical experiments were carried out at room

temperature and ambient pressure, employing 0.5 M sulphuric

acid as the electrolyte solution.

2.4. Characterization methods

X-ray diffraction (XRD) patterns were recorded with a Philips

Xpert X-ray diffractometer using Cu Ka radiation. For transmission electron microscopy (TEM) studies, the catalysts

dispersed in ethanol were placed on a copper grid and the TEM

images were collected with a JEOL 2010 TEM equipped with an

Oxford ISIS system. The operating voltage on the microscope

was 200 keV. All images were digitally recorded with a slow-scan

charge-coupled device (CCD) camera.

2.5. Electrochemical measurements

All electrochemical studies were carried out with an Autolab

PGSTAT 30 (Eco Chemie) potentiostat/galvanostat. A classical

three-electrode cell consisting of Ag/AgCl (3 M KCl) reference

electrode, a platinum plate (5 cm2) counter electrode, and a

glassy carbon working electrode (the diameter of working

electrode is 5 mm, 0.196 cm2) was used for the cyclic voltammetry (CV) studies. The CV experiments were performed with

0.5 M H2SO4 solution in the absence and presence of 0.5 M

HCOOH at a scan rate of 50 mV sÀ1. All the solutions were

prepared with ultra-pure water (Millipore, 18 MU). The electrolytes were degassed with nitrogen gas before the electrochemical measurements. All the electrochemical data were

collected at room temperature.

3.

Results and discussion

3.1. Physiochemical characterization of the catalysts

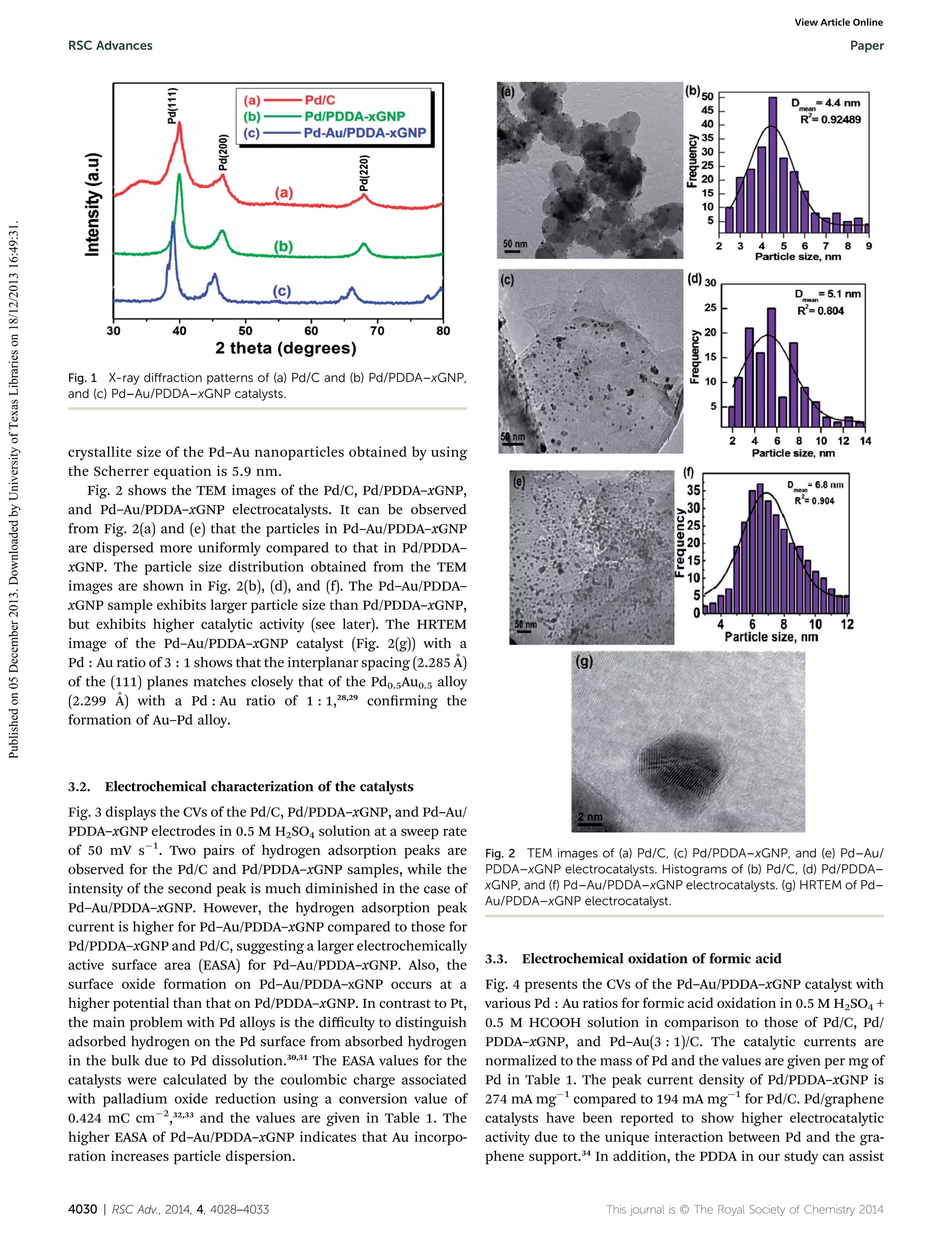

The XRD patterns of the Pd/C, Pd/PDDA–xGNP, and Pd–Au/

PDDA–xGNP samples are shown in Fig. 1. All the three

samples show reections characteristic of a face-centered

cubic (fcc) lattice, corresponding to the structures of Pd or

Pd–Au.26,27 The reections of Pd–Au (3 : 1 atomic ratio) are

shied to lower angles compared to those of Pd due to the

larger size of Au, conrming the alloying of Au with Pd. The

RSC Adv., 2014, 4, 4028–4033 | 4029](https://image.slidesharecdn.com/highlyactivepdandpdaunanoparticlessupportedonfunctionalizedgraphenenanoplateletsforenhancedformicaci-131218105424-phpapp01/75/Highly-active-pd-and-pd-au-nanoparticles-supported-on-functionalized-graphene-nanoplatelets-for-enhanced-formic-acid-oxidation-2-2048.jpg)