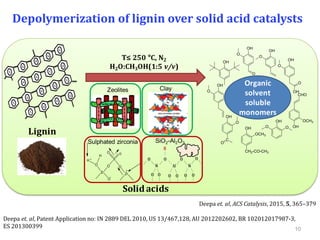

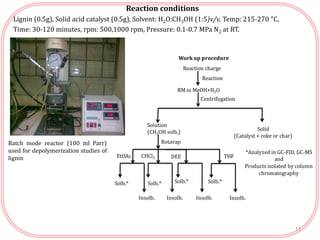

The document summarizes research on the depolymerization of lignin over heterogeneous catalysts having acidic functionality. Key points:

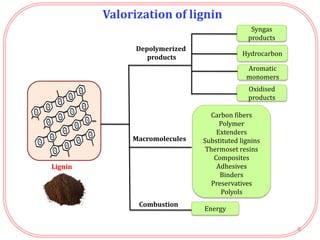

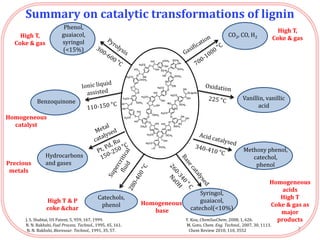

- Lignin can be converted into high-value chemicals but is currently underutilized. Heterogeneous catalysts can aid in the depolymerization of lignin into aromatic monomers.

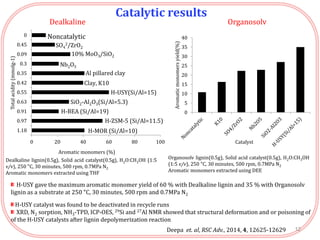

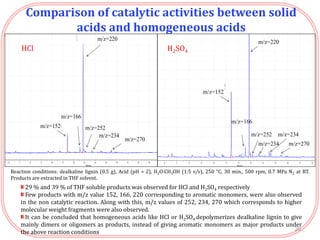

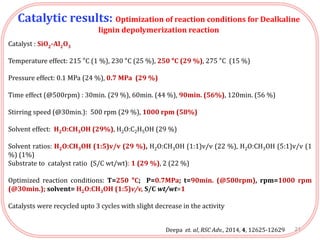

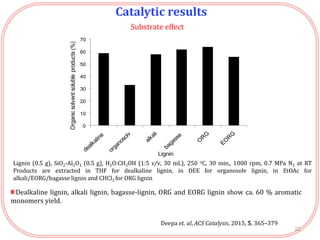

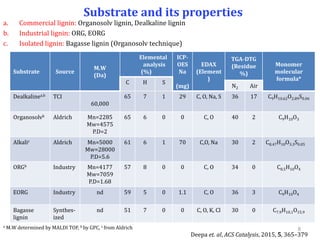

- Testing of various solid acid catalysts showed H-USY zeolite gave the highest yield (60%) of aromatic monomers from depolymerization of dealkaline lignin. However, H-USY deactivated after reuse.

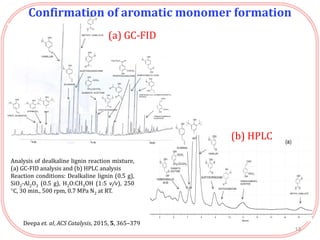

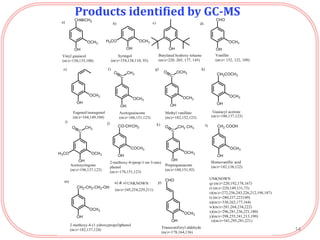

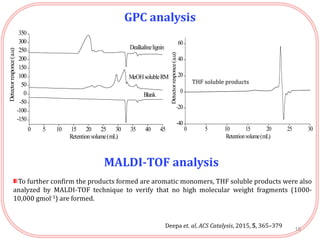

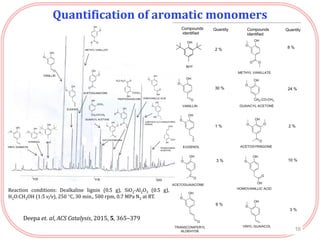

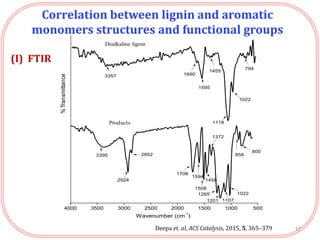

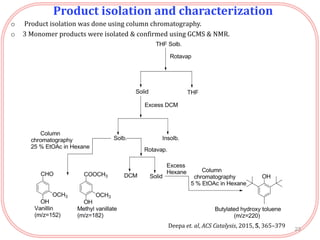

- Products were analyzed using GC-MS, GPC and MALDI-TOF, confirming the formation of aromatic monomers rather than high molecular weight compounds. FTI

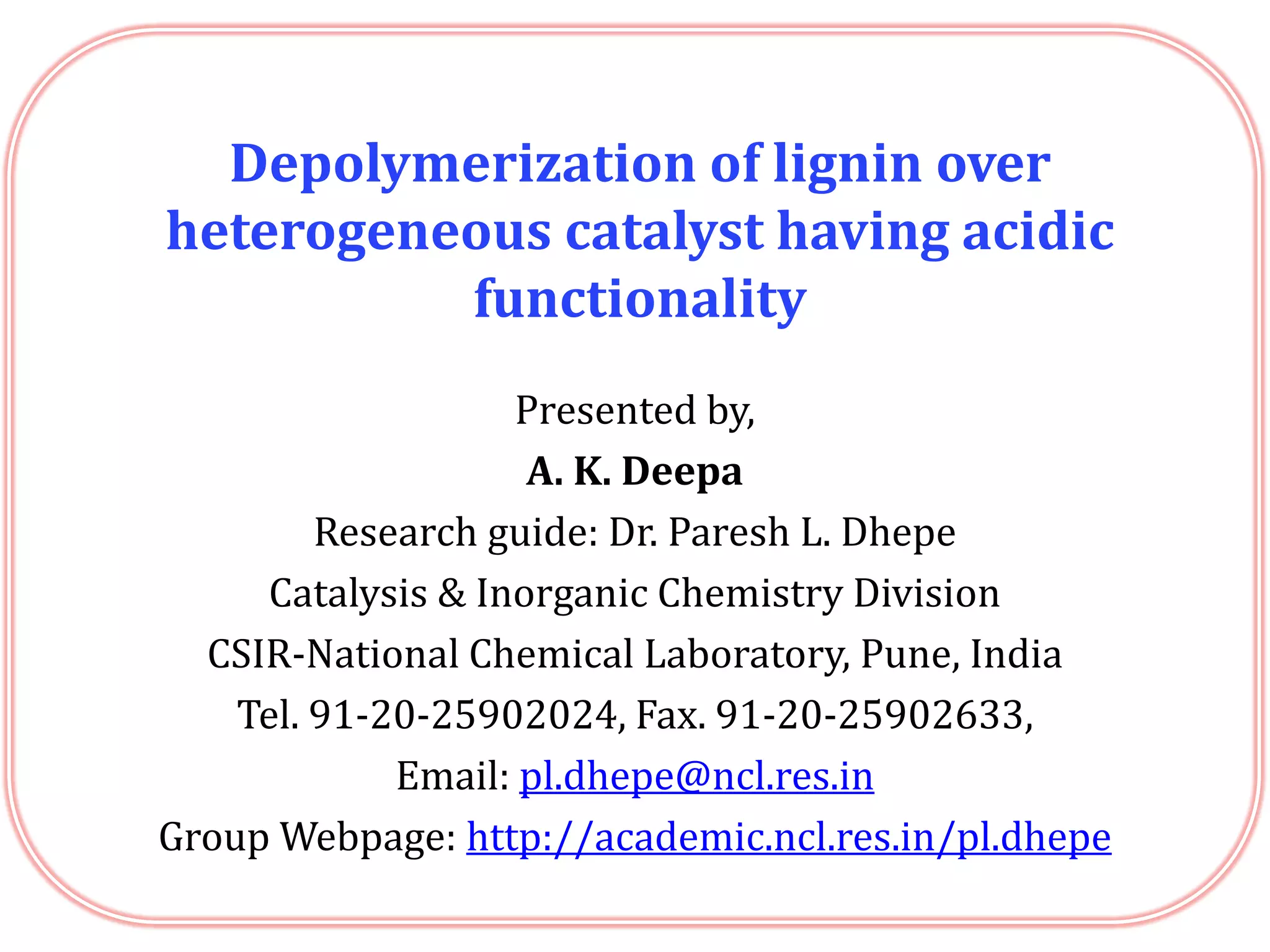

![Properties of solid acids (for lignin depolymerization)

aBrunauer–Emmett–Teller surface area, bPorevolume, bPorediameter [Autosorb1C Quantachrome, instrument]

dAcidity measured by means of TPD of NH3[Micrometrics Autochem-2910 instrument] .

Catalyst Structure

Nitrogen sorption NH3-TPDd

BET SAa

(m2g-1)

Vb

(cm3g-1)

Dc

(nm)

Weak acid

sites

(mmolg-1)

Stong acid

sites

(mmolg-1)

Total

acidity

(mmolg-1)

H-USY (Si/Al=15) Micro 873 0.45 0.61 0.06 0.49 0.55

H-ZSM-5 (Si/Al=11.5) Micro 423 0.22 0.60 0.37 0.61 0.97

H-BEA (Si/Al=19) Micro 761 0.34 0.60 0.25 0.66 0.91

H-MOR (Si/Al=10) Micro 528 0.22 0.59 0.5 0.65 1.18

Nb2O5 -- 115 -- -- 0.30 -- 0.30

SO42-/ZrO2 -- 84 0.02 -- nd nd nd

Clay (K10) Layered 246 0.3 -- 0.09 0.33 0.42

Al pillared clay Layered nd nd nd nd nd nd

SiO2-Al2O3 Micro-meso 532 0.82 4.90 0.17 0.46 0.63

10%MoO3/SiO2 Nonporous nd nd nd 0.09 - 0.09

9](https://image.slidesharecdn.com/lignin-solidacid-heterogeneouscatalyst-depolymerization-aromaticmonomer-151102084152-lva1-app6892/85/Lignin-depolymerization-aromatic-monomers-solid-acid-heterogeneous-catalyst-A-K-Deepa-Paresh-Dhepe-NCL-9-320.jpg)