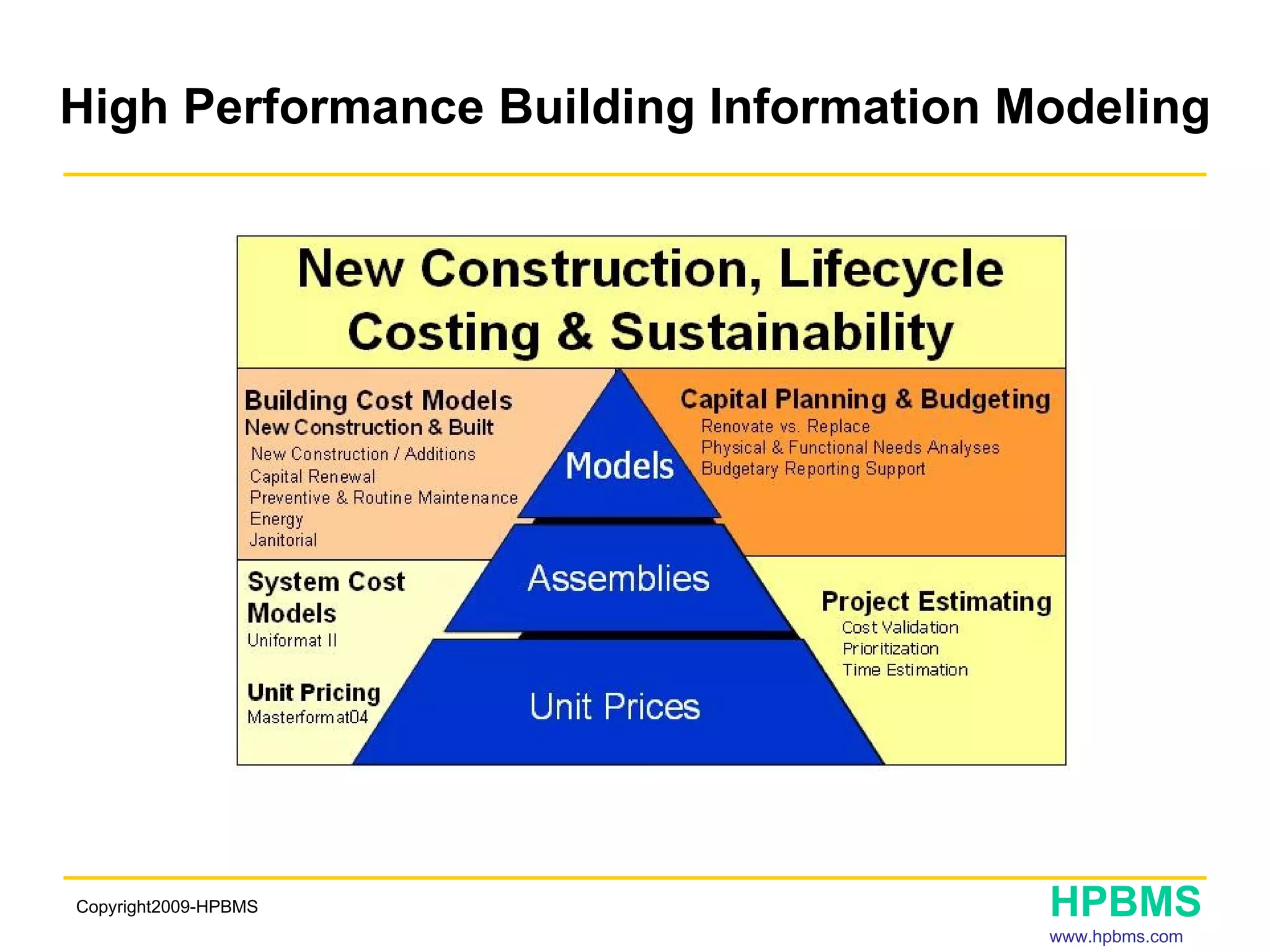

HPBMS is a framework for managing building lifecycles from conceptual planning through facilities operations. It provides standardized processes, reference cost databases, benchmarking and analytics to improve planning, budgeting, and cost estimating accuracy. HPBMS ensures a uniform cost control framework throughout a building's lifecycle from initial design through deconstruction. It also supports sustainability and high-performance building management, which are core to strategic organizational decision making.