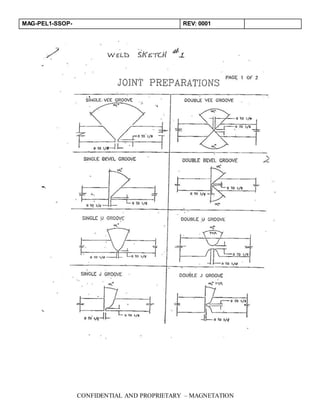

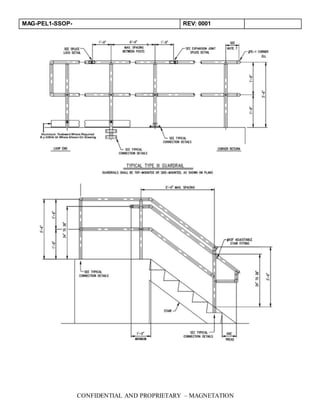

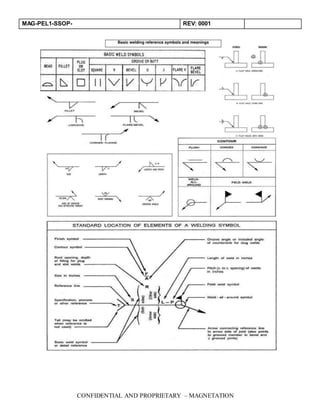

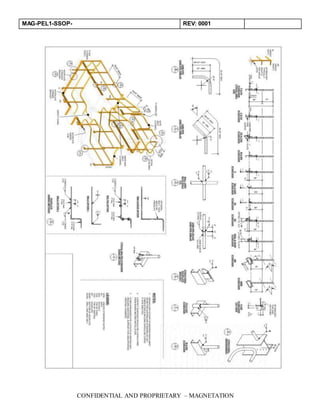

This document outlines safety procedures and specifications for fabricating handrails. It details required personal protective equipment, tools, and materials. Railings must be made of 1-1/2" pipe and withstand loads of 200 lbs. Welds must have full coverage and be ground smooth. The standard calls for certified welders and finishing rails in safety paint before installation. Proper cleanup of the work area is also specified.