Critical levels for monitoring ground anchor systems provide essential safety checks during deep excavation projects. They define an alert level and work suspension level to monitor anchor loads. Exceeding the alert level requires close monitoring, while exceeding the work suspension level stops work. This case study of a large excavation project in Singapore demonstrates how critical level monitoring, conservative design parameters, and controlled pre-loading of anchors ensures the safety and performance of complex temporary earth retaining systems.

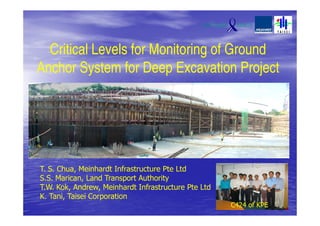

![Deformation of

retaining wall (Plaxis)

80.0

85.0

90.0

95.0

100.0

105.0

110.0

115.0

-10 10 30 50 70 90 110 130 150 170 190

Horizontal Displacement [mm]

ReducedLevel[m]..

Exc to belowS1

Exc to belowS2

Exc to belowGA3

Exc to belowGA4

Exc to belowGA5

Exc to FL of tunnel

Construct tunnel

backfill to below

GA5 & remove GA5

backfill to below

GA4 & remove GA4

backfill to below

GA3 & remove GA3

backfill to belowS2

& remove S2

backfill to belowS1

& remove S1

backfill to GL

Strut 1, RL112.0m

Strut 2, RL107.5m

Ground Anchor 3,

RL104.0m

Ground Anchor 4,

RL101.0m

Ground Anchor 5,

RL98.5m

Formationlevel

RL95.2m

11](https://image.slidesharecdn.com/871c8a11-a822-4a38-8dd7-0d78f0d8f5e2-151028083414-lva1-app6892/85/ICDE2006-Singapore-11-320.jpg)