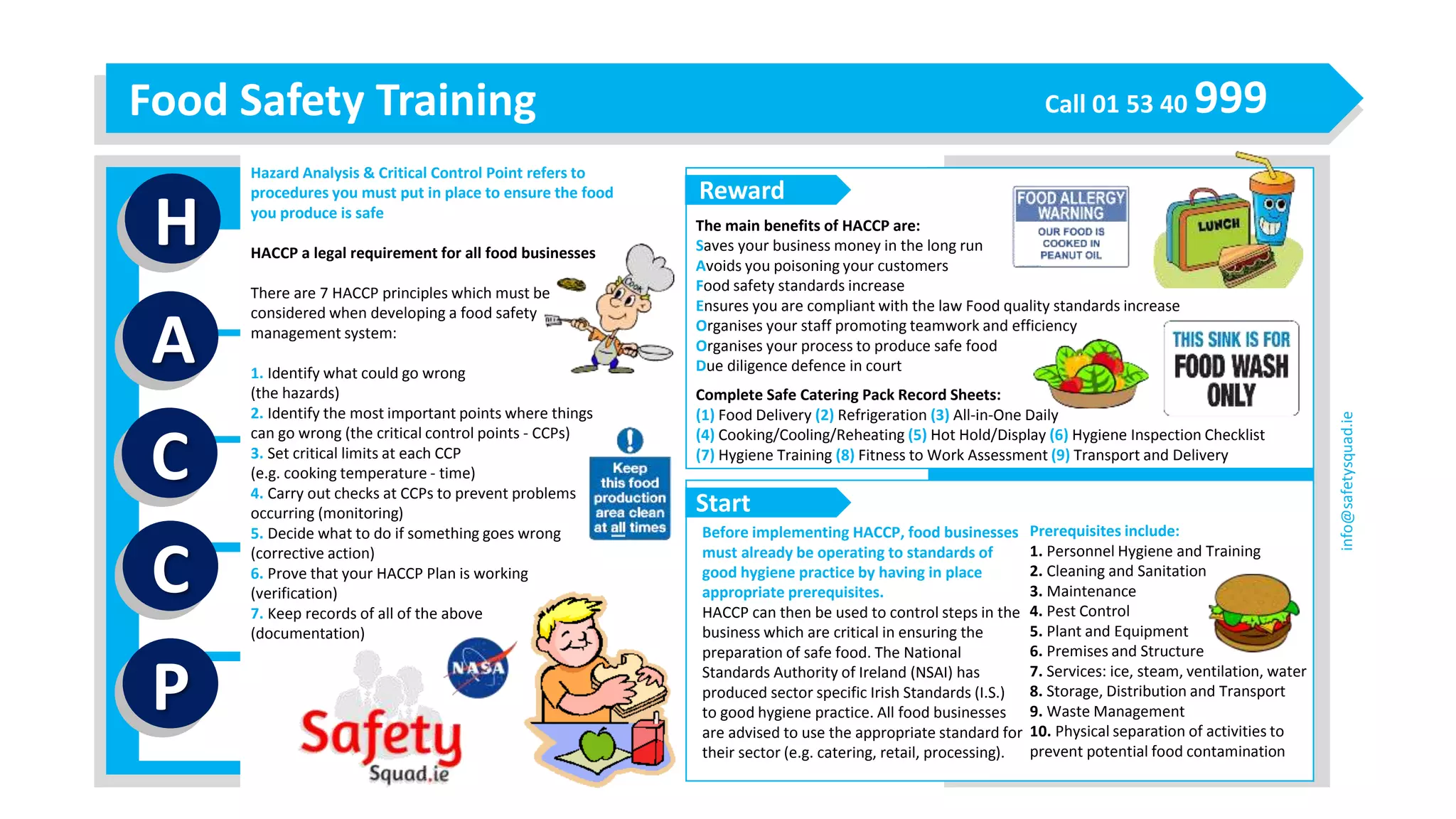

This document provides information on Hazard Analysis and Critical Control Point (HACCP), a food safety management system. It outlines the 7 principles of HACCP, which include identifying hazards, critical control points, critical limits, monitoring procedures, corrective actions, verification, and record keeping. The document also lists prerequisites that must be in place before implementing HACCP, such as personnel hygiene and training, cleaning and sanitation, maintenance, and pest control. Finally, it provides examples of sector-specific Irish Standards for good hygiene practice in catering, retail, and food processing.