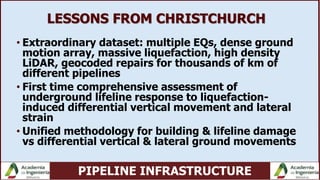

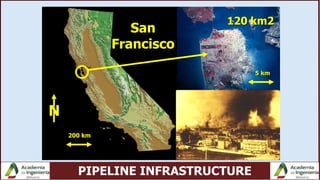

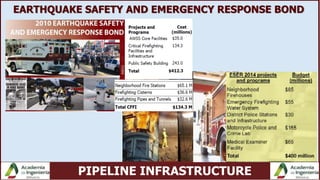

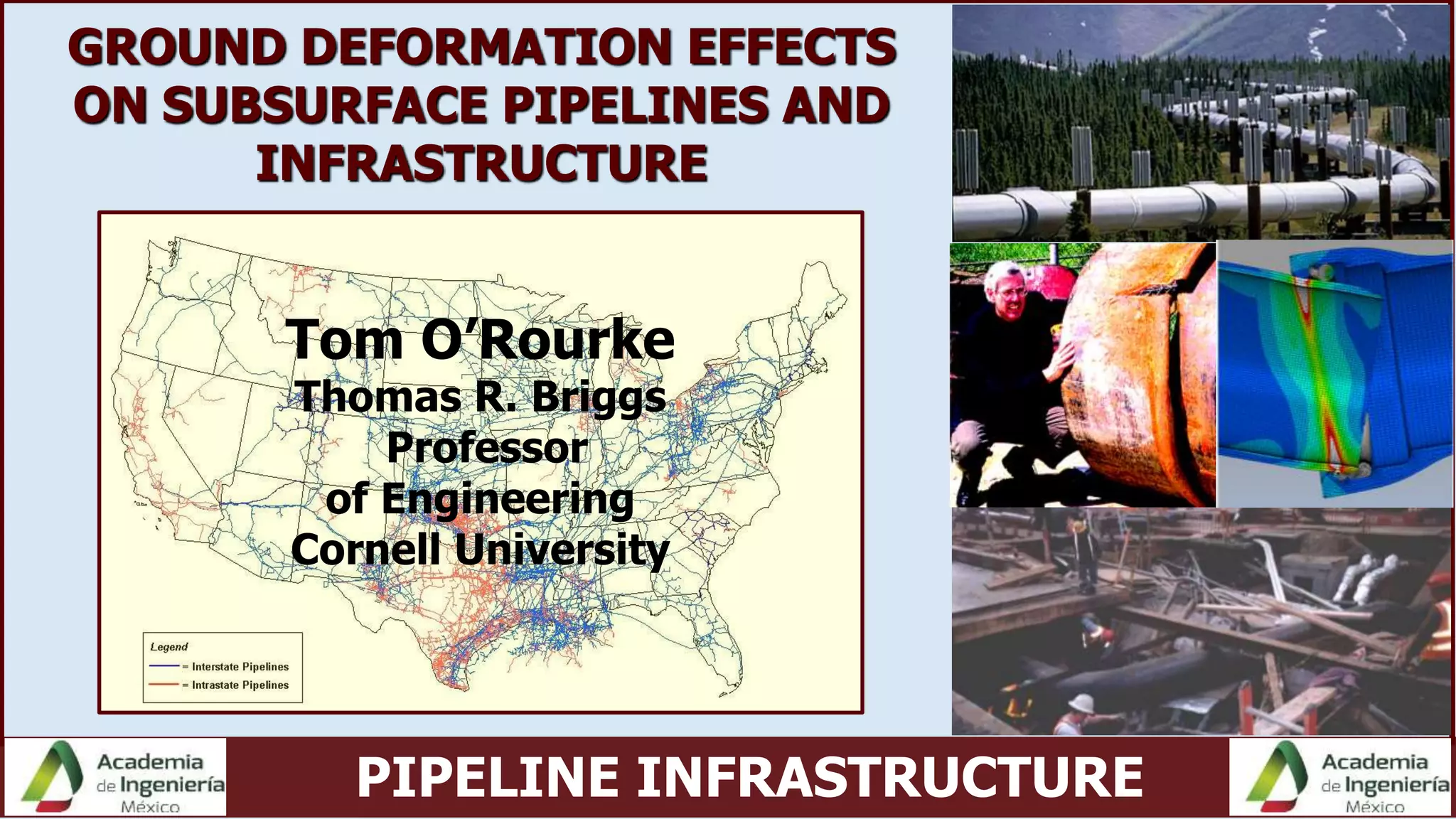

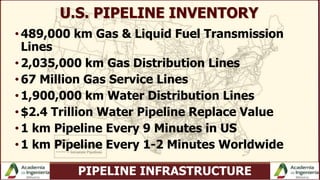

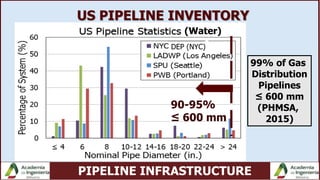

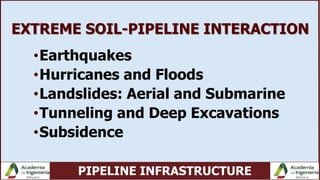

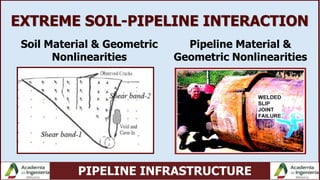

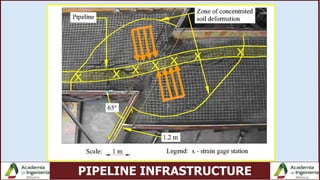

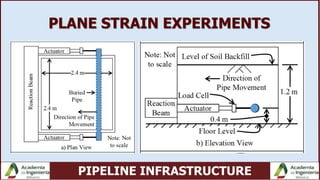

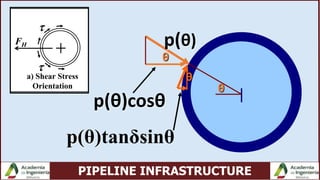

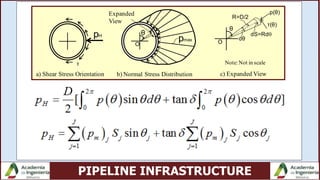

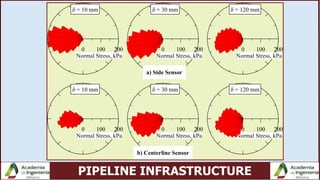

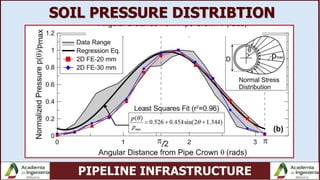

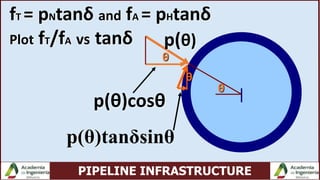

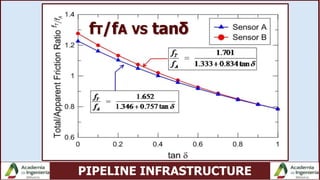

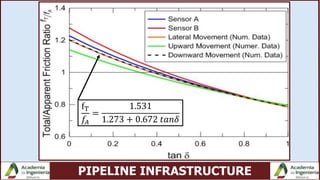

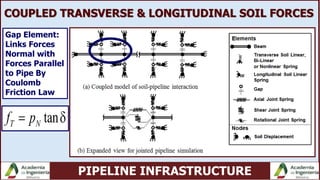

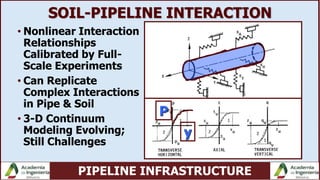

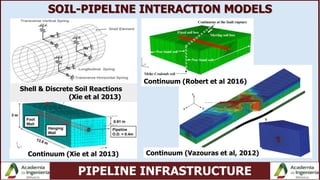

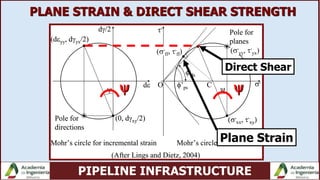

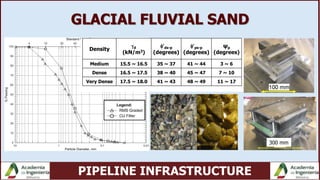

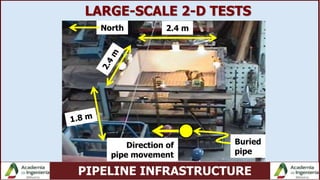

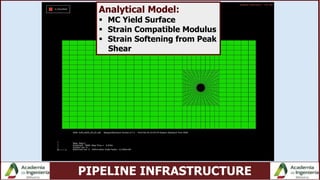

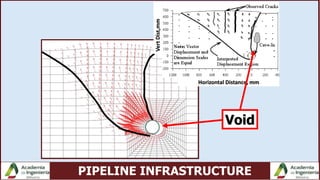

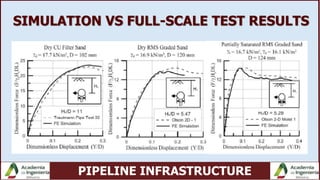

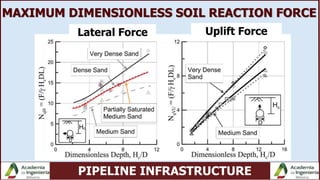

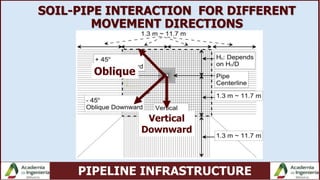

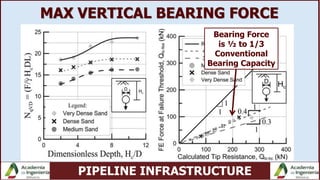

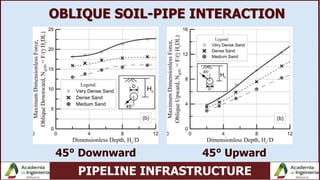

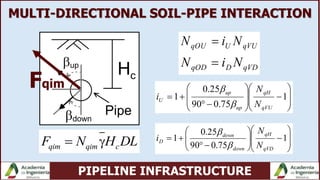

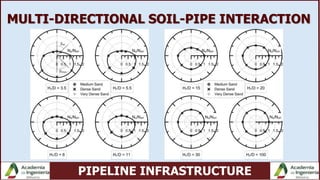

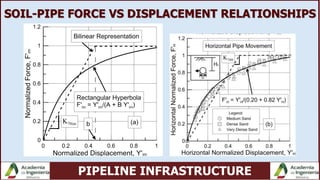

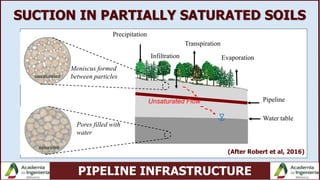

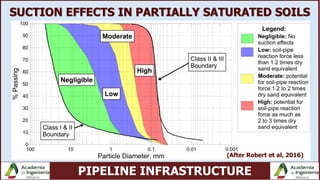

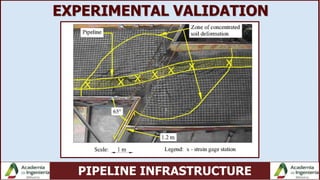

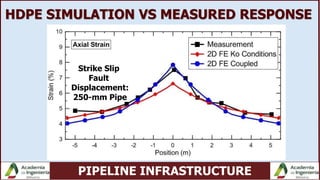

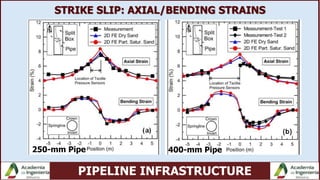

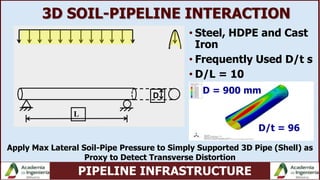

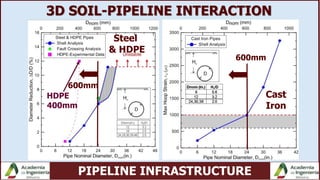

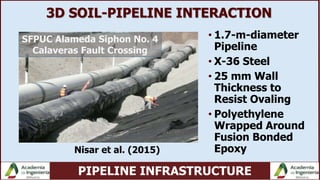

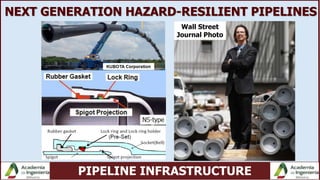

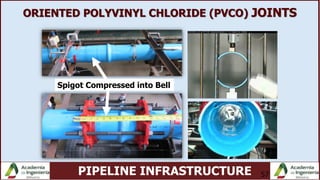

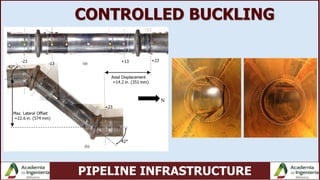

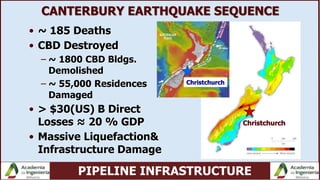

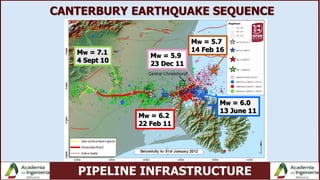

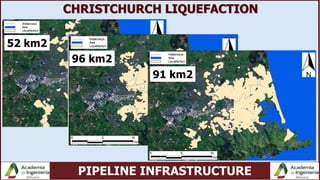

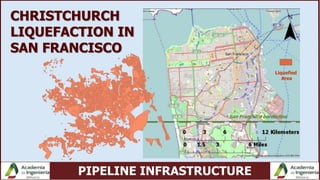

This document discusses pipeline infrastructure and soil-pipeline interaction. It covers several topics: underground assets and the large inventory of pipelines in the US and worldwide; the interface between soil and pipes; 2D and 3D modeling of soil-pipeline interaction; next generation hazard-resistant pipelines; and the impact of ground deformation on pipeline performance. The document provides examples of full-scale testing and numerical modeling to understand complex soil-pipeline behavior during different loading conditions.

![PIPELINE INFRASTRUCTURE

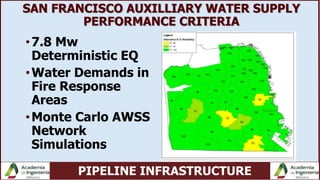

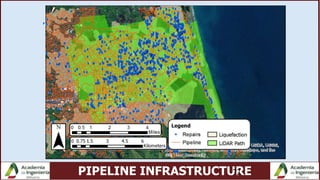

SCREENING CRITERIA

• Repair Locations Checked by GIS

• Discount Landslides/Rockfall Areas

• Assume Poisson Distribution for Repairs

( ) (1p RR x p

Poisson distribution: μ = (RR)x, and σ = [(RR)x]½

Sampled repairs follow normal distr. (central limit theorem)

1

1 2 2

c

c

p

x RR

](https://image.slidesharecdn.com/orourkemexicanacademyofengineering-180202210341/85/Ground-deformation-effects-on-subsurface-pipelines-and-infrastructure-73-320.jpg)