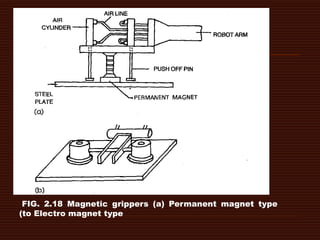

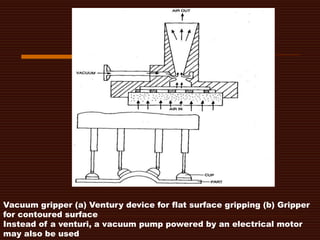

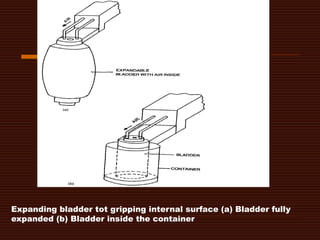

Magnetic grippers are used to handle ferrous metal parts and offer advantages like tolerating variations in part size, fast pickup times, and the ability to handle parts with holes using only one surface. However, residual magnetism and picking up multiple sheets from a stack can be disadvantages. Electromagnets are easier to control but require power, while permanent magnets do not require power but require a means to release parts. Adhesive and vacuum grippers can also be used but have limitations like losing tackiness and difficulty controlling amount scooped, respectively. Other grippers include hooks, scoops, and inflatable devices for fragile objects.