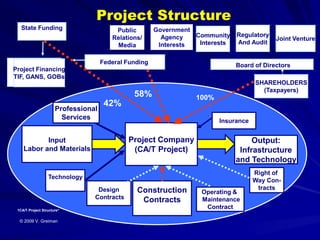

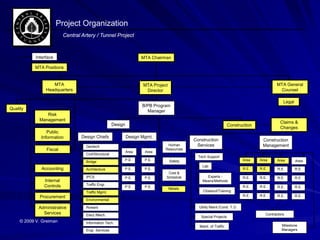

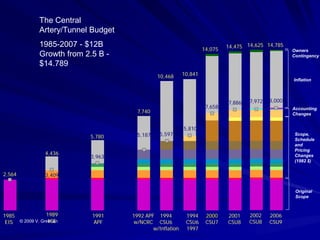

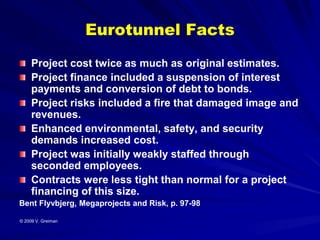

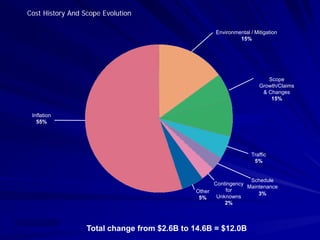

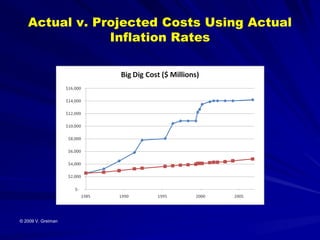

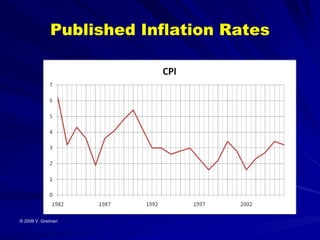

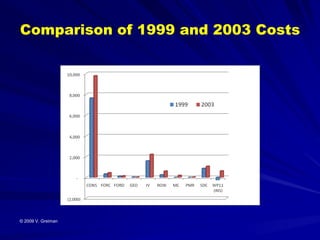

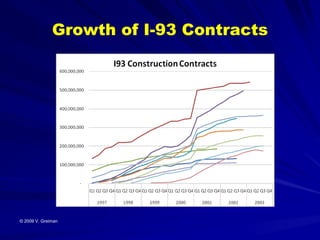

This document summarizes a presentation about lessons learned from the Big Dig project in Boston. It provides background on the project, discusses existing literature on cost overruns in mega projects, and analyzes cost and schedule data over the life of the Big Dig. The presentation examines project structure, organization, and factors that contributed to cost increases from the initial $2.5 billion estimate to the final $14.8 billion. It aims to identify techniques for improving cost estimation and management of large infrastructure projects.