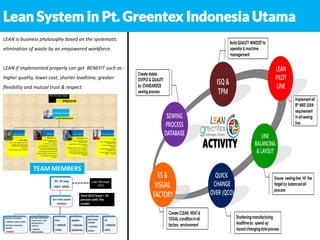

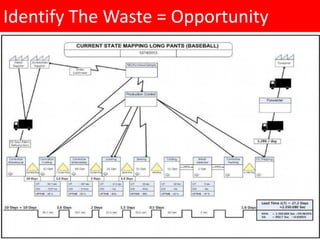

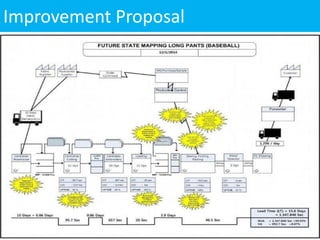

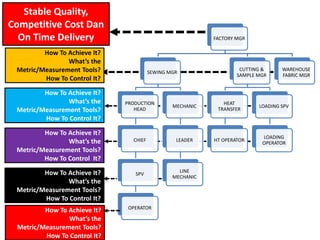

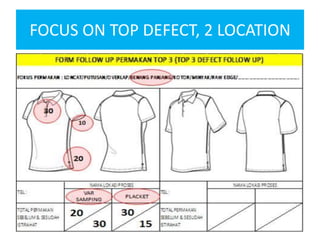

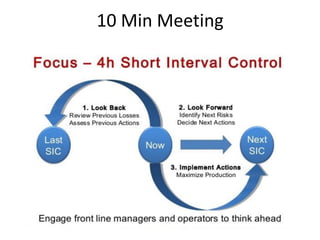

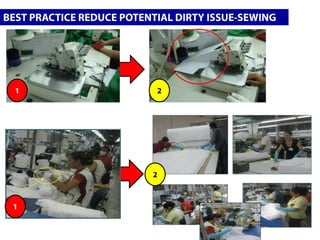

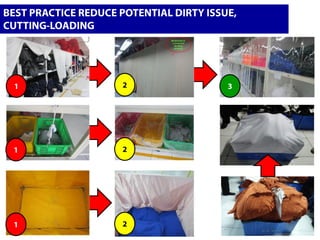

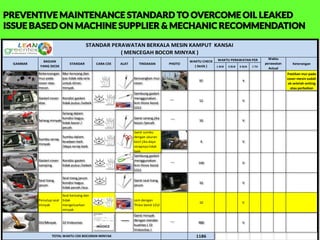

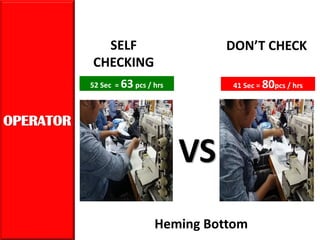

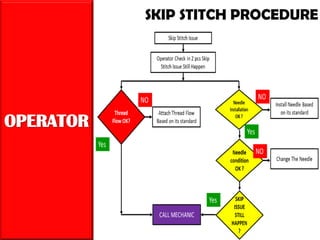

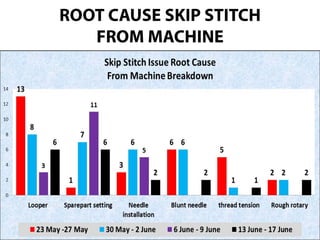

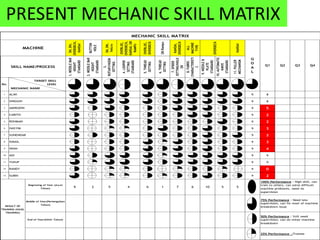

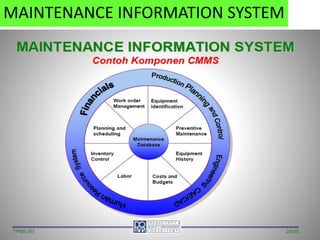

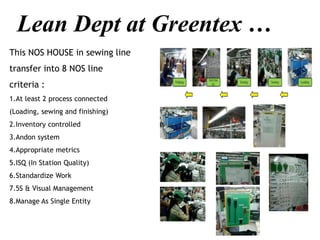

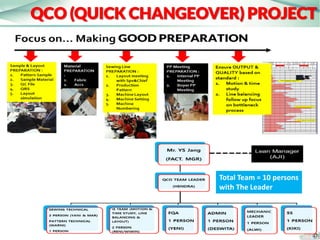

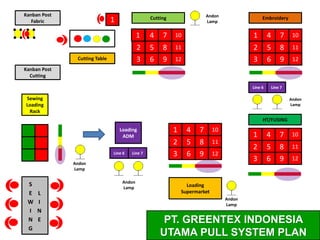

The document outlines Pt. Greentex Indonesia Utama's plans to implement Lean systems and principles to achieve benefits like higher quality, lower costs, and shorter lead times. It discusses identifying and eliminating waste opportunities. It also provides information on improvement proposals, activities, metrics, and responsibilities for quality control across different departments like sewing, cutting, and maintenance. Visual standards and preventative maintenance procedures are established to reduce defects from issues like oil leaks and skips stitches. The implementation of a maintenance information system and expanding successful lines from single to multi-process "Lean Lines" are also covered.