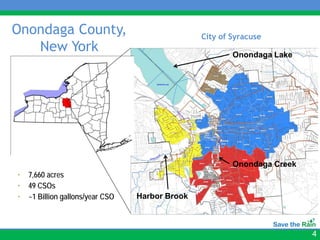

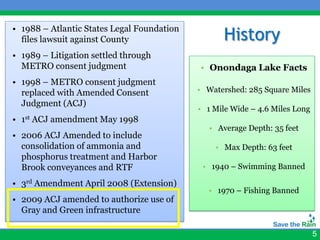

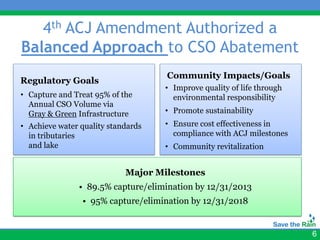

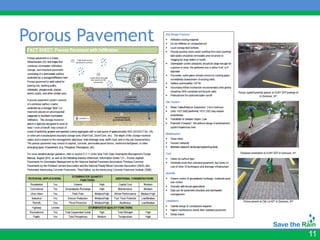

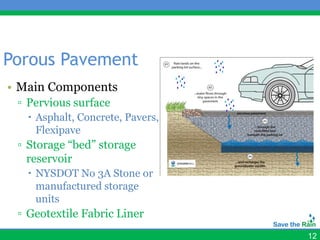

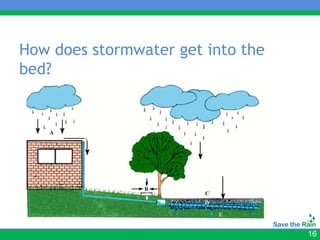

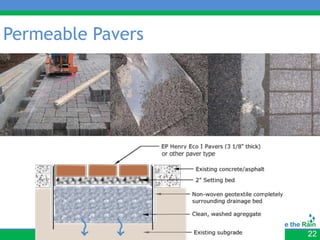

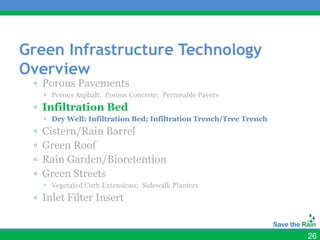

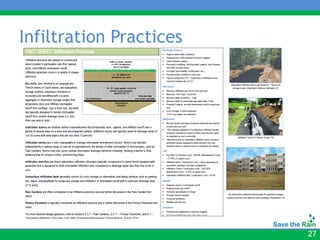

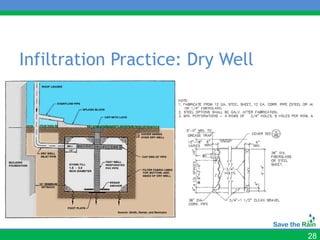

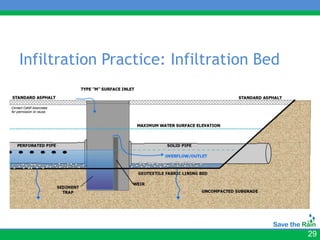

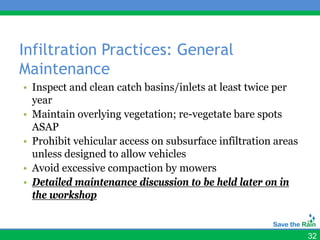

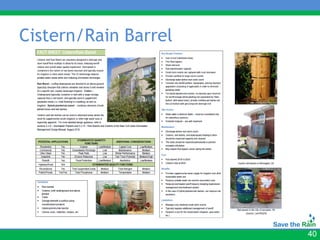

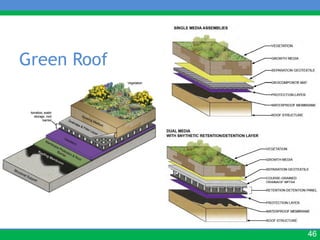

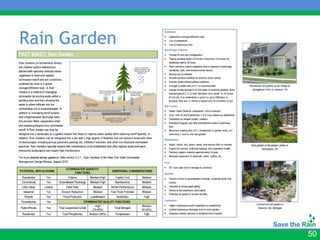

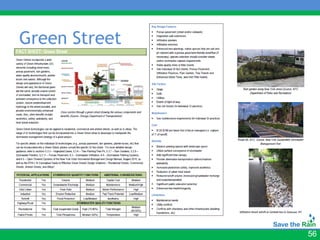

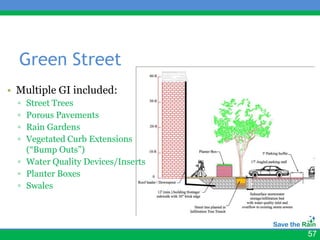

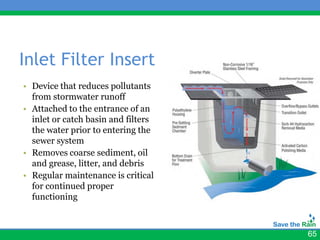

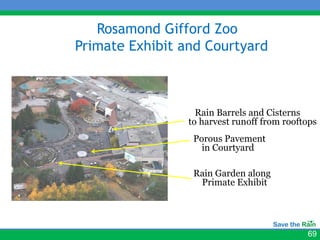

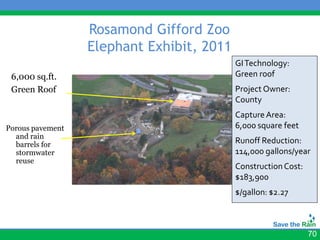

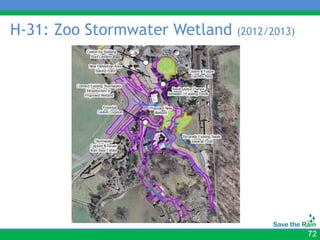

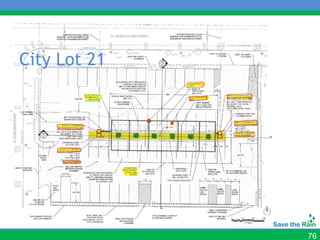

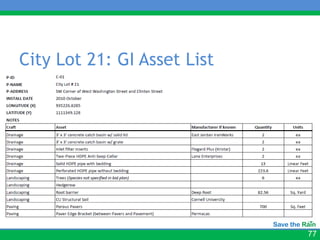

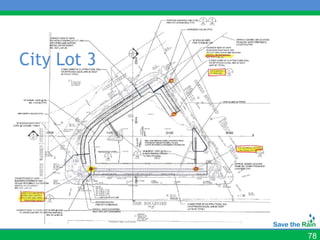

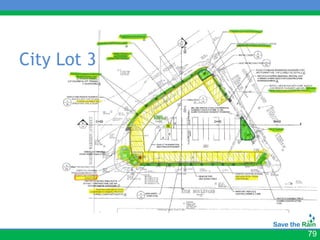

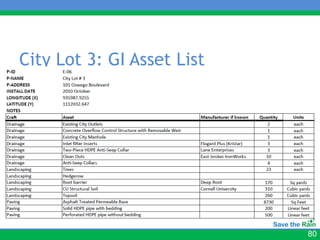

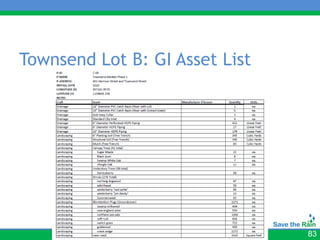

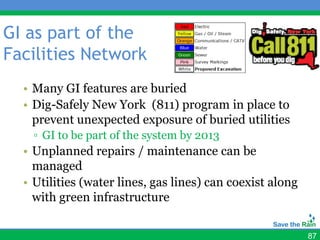

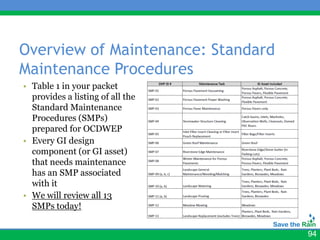

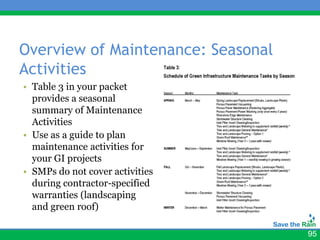

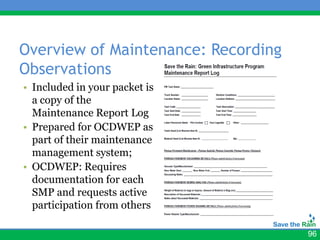

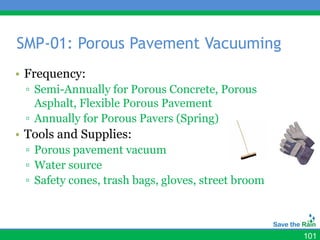

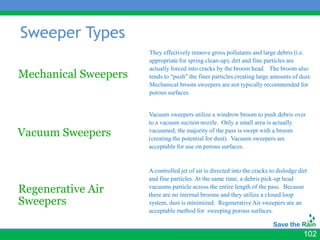

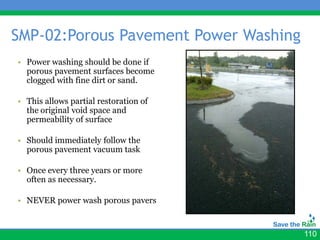

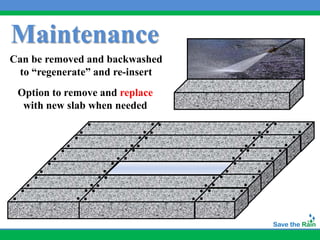

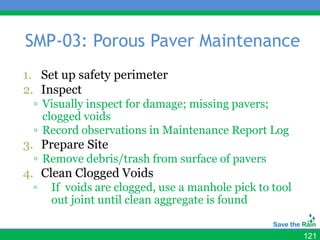

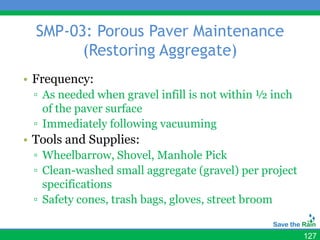

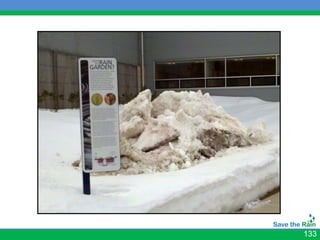

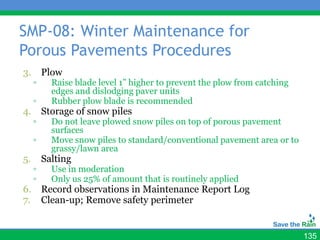

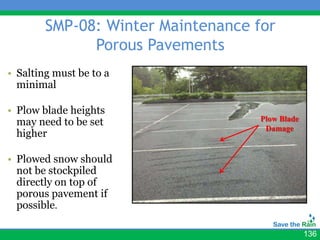

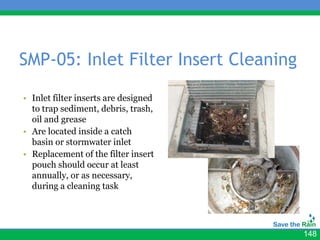

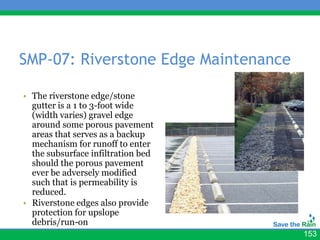

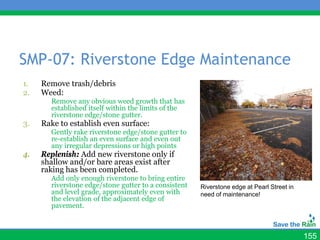

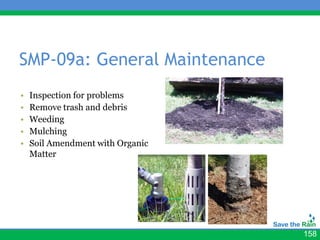

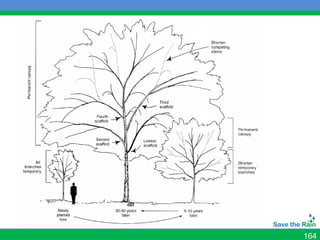

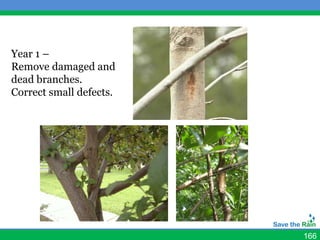

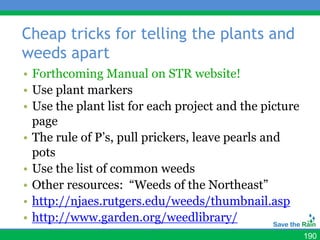

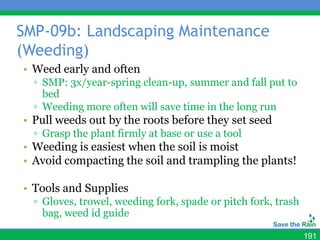

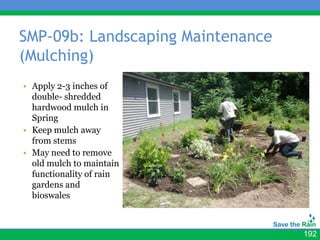

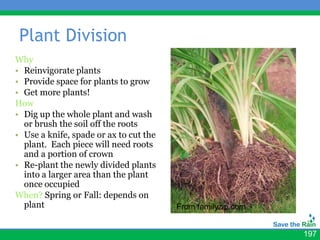

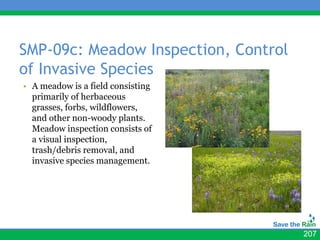

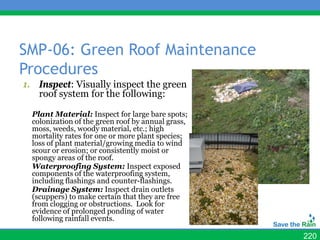

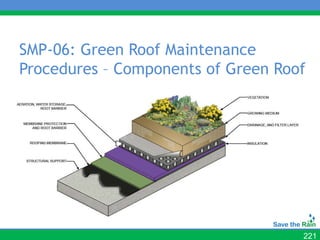

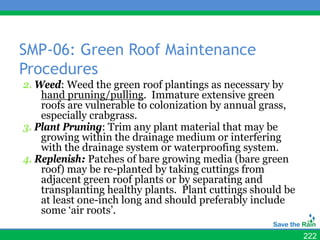

The document outlines the green infrastructure maintenance training led by various speakers to ensure compliance with the Onondaga Lake Amended Consent Judgment. It details the history and goals of the stormwater management initiatives in Onondaga County, including the implementation of green infrastructure technologies to improve water quality. Specific maintenance tasks and practices for various green infrastructure components such as porous pavements, rain gardens, and green roofs are discussed to promote effective upkeep and functionality.