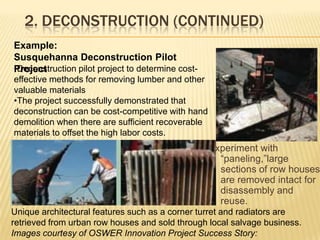

Green manufacturing aims to make products and processes safer for the environment and human health. It focuses on using less toxic materials, post-consumer recycled content, locally sourced materials, and renewable energy. Interface, a carpet manufacturer, has transitioned to using bio-based raw materials, sources over 27% of its energy from renewables, and has eliminated 50% of waste costs. Deconstruction is the careful dismantling of structures to maximize reuse of materials and minimize landfill waste. Reuse keeps goods out of the waste stream by redistributing still-usable items, while recycling collects, sorts, and reprocesses used materials into new raw materials. Remanufacturing disassembles worn equipment to reuse sound parts and build new products