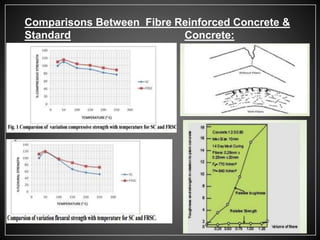

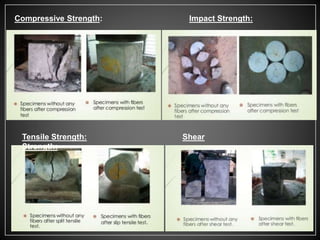

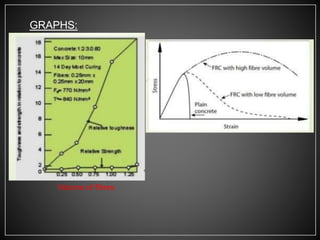

Fibre reinforced concrete is a composite material consisting of cement, concrete and small fibres distributed throughout for increased strength and crack resistance. The fibres improve tensile strength, flexural strength, impact resistance and durability. Different fibre types include steel, glass, polypropylene and synthetic fibres. The mechanical properties of fibre reinforced concrete depend on fibre type, size, volume and distribution, with higher fibre content increasing tensile strength, flexural strength, toughness and modulus of elasticity. Uniform dispersion of fibres is important to prevent balling during mixing.