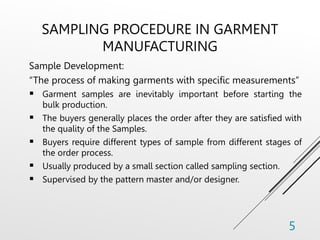

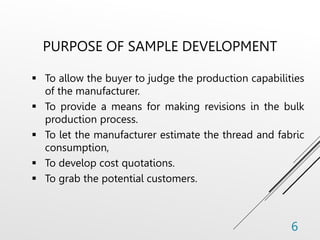

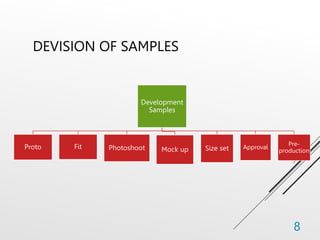

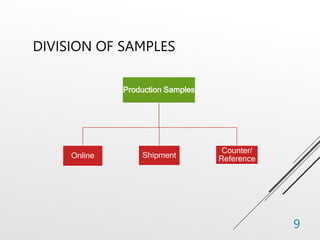

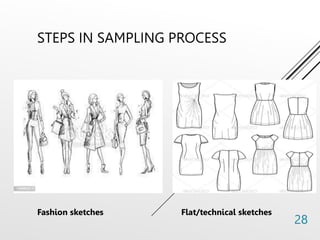

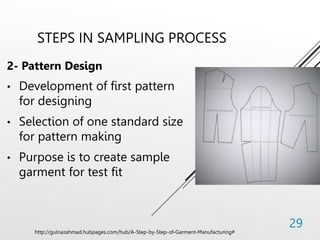

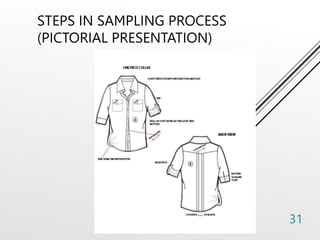

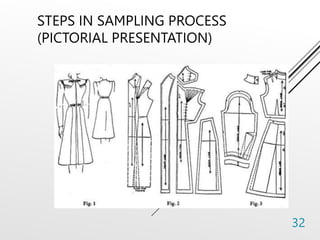

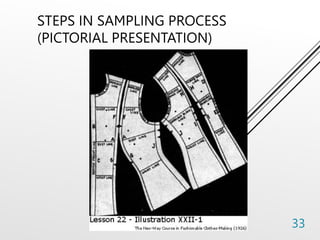

This document discusses the sampling process in garment manufacturing. It describes the different types of samples including design/proto samples, fit samples, photoshoot samples, mock up samples, size set samples, approval samples, pre-production samples, online samples, and shipment samples. It explains that sampling is important to attract buyers, generate orders, and ensure good quality and affordable price. The key steps in sampling are sketching designs, creating patterns, and making samples to test fit and get feedback before bulk production.