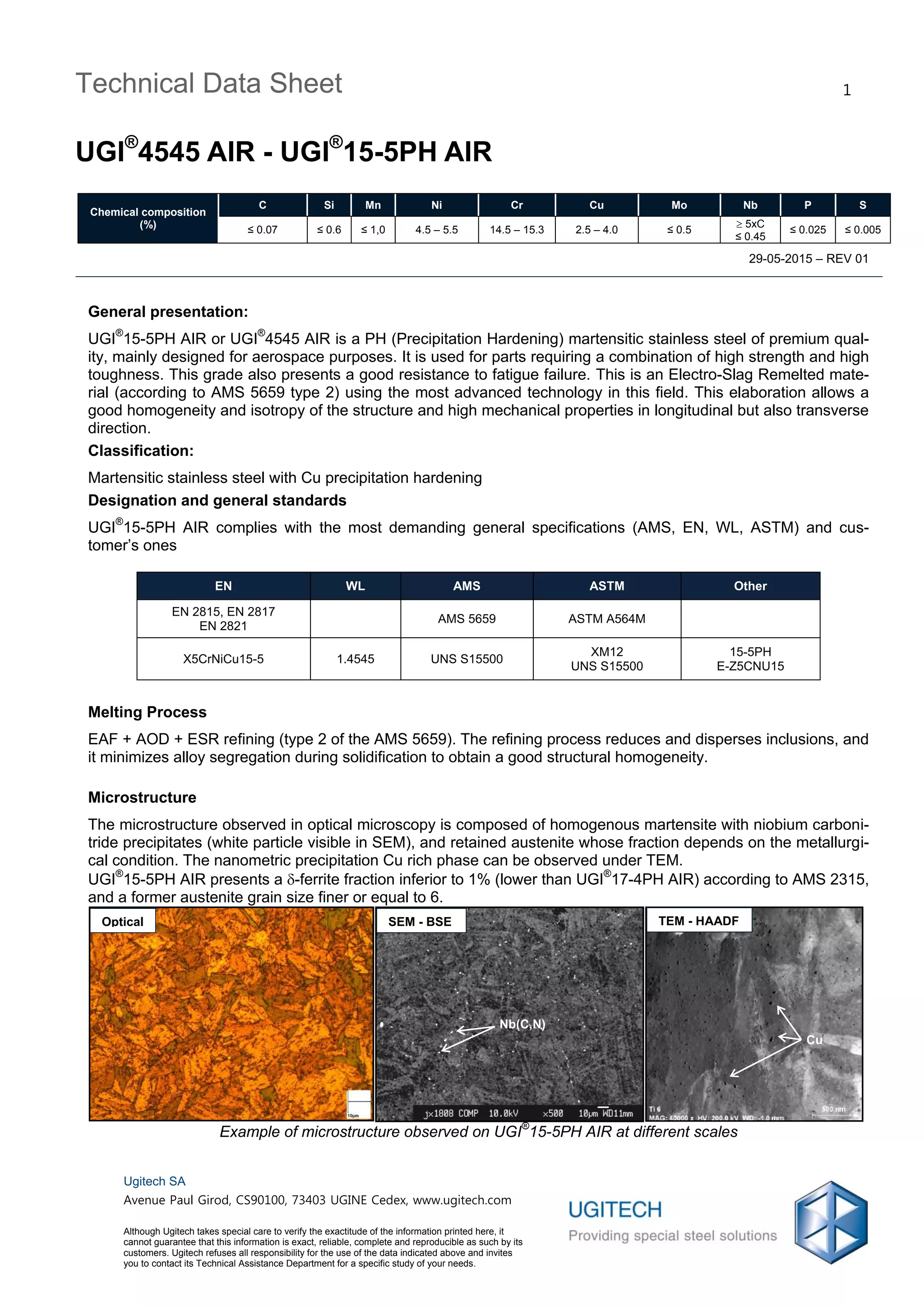

UGI® 15-5PH AIR is a precipitation hardened martensitic stainless steel designed for aerospace applications. It has a chemical composition of C, Si, Mn, Ni, Cr, Cu, Mo, Nb, P, and S. The steel is produced using electro-slag remelting which results in a homogeneous microstructure of martensite and retained austenite with nanometer-scale copper precipitates. Heat treatments including solution annealing and aging are used to achieve desired mechanical properties ranging from high strength to increased toughness depending on the aging temperature. Typical properties include a tensile strength of 1000-1310 MPa, yield strength of 860-1170 MPa, and impact

![29-05-2015 – REV 01

Technical Data Sheet

UGI®

4545 AIR - UGI®

15-5PH AIR

2

Chemical composition

(%)

C Si Mn Ni Cr Cu Mo Nb P S

≤ 0.07 ≤ 0.6 ≤ 1,0 4.5 – 5.5 14.5 – 15.3 2.5 – 4.0 ≤ 0.5

5xC

≤ 0.45

≤ 0.025 ≤ 0.005

Ugitech SA

Avenue Paul Girod, CS90100, 73403 UGINE Cedex, www.ugitech.com

Although Ugitech takes special care to verify the exactitude of the information printed here, it

cannot guarantee that this information is exact, reliable, complete and reproducible as such by its

customers. Ugitech refuses all responsibility for the use of the data indicated above and invites

you to contact its Technical Assistance Department for a specific study of your needs.

Physical properties

The table below shows the values of physical properties for UGI®

15-5PH AIR. These values are dependent on

the metallurgical condition; please contact us for additional information.

Temperature Density

thermal ex-

pansion be-

tween 20°C

and T

Young’s

modulus

Thermal

conductivity

Electrical

resistivity

Specific

heat

Magnetic

properties

[°C] [kg/dm3] [10

-6

K

-1

] [GPa] [W/(m.K)] [µΩ.cm] [J/(kg.K)]

20 7.8 200 16 71 500

ferromagnetic

100 10.5 195

200 11.1 185

300 11.5 175

400 11.9 170

Heat treatments and guaranteed levels of mechanical properties

Heat treatments carried out on UGI®

15-5PH AIR are composed of two steps:

- Austenitisation, whose purpose is to get alloying elements especially Cu into supersaturated martensite

- Aging, whose purpose is to precipitate Cu (precipitation hardening) and, in some case to form reverted

austenite to increase toughness. The mechanical properties, trade-off between strength and toughness,

are adjusted by the aging temperature.

Austenitisation

Solution annealing is performed around 1030-1050°C, and is interrupted by oil quenching or alternatively by air

cooling for small section parts. In this condition (called condition A) hardness is intermediate because Cu precipi-

tation hardening is not effective. Hence, the A-condition is often chosen to carry out machining or cold forming

operations. In that case, we recommend performing a stress relief treatment at 300°C for 1 hour after austenitisa-

tion, in order to stabilize the material and avoid quench-cracking issues.

Aging

Aging treatments are performed after solution treatment to make Cu rich phases precipitate and adjust mechani-

cal properties. After aging, the material is in the solution and aged condition, also called H-condition. Aging treat-

ments can be performed between 480°C (condition H900) and 620°C (condition H1150). The condition H900 cor-

responds to the peak of hardening, for which the Cu precipitates induce a maximum of hardness. For higher tem-

perature the hardness/strength decreases when increasing aging temperature, due to the growth of the precipi-

tates. Beyond 580°C some reverted austenite is formed during the aging which results in a increase of the tough-

ness but a drop of the strength. The condition H1025 is often chosen by customers because it leads to an optimal

trade-off between strength and toughness.](https://image.slidesharecdn.com/ged2504-150708134439-lva1-app6891/85/Ged-2504-2-320.jpg)