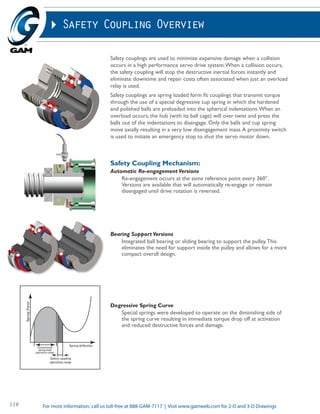

The document provides an overview of safety couplings, which are used in high performance servo drive systems to minimize damage during collisions. Safety couplings instantly stop destructive inertial forces when a collision occurs, eliminating downtime and repair costs. They are spring-loaded couplings that transmit torque until an overload occurs, causing the hub to over-twist and disengage the coupling. This protects the system from damage.