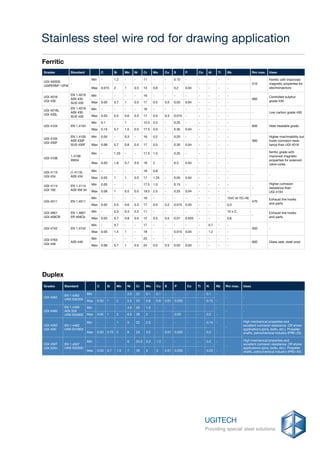

This document provides information on various grades of stainless steel wire rod for drawing applications, including their standard chemical compositions and maximum yield strengths. It lists the elemental ranges for carbon, silicon, manganese, nickel, chromium, molybdenum and other elements in each grade, along with their intended uses such as for magnetic properties, corrosion resistance, heat treatability, and machinability.