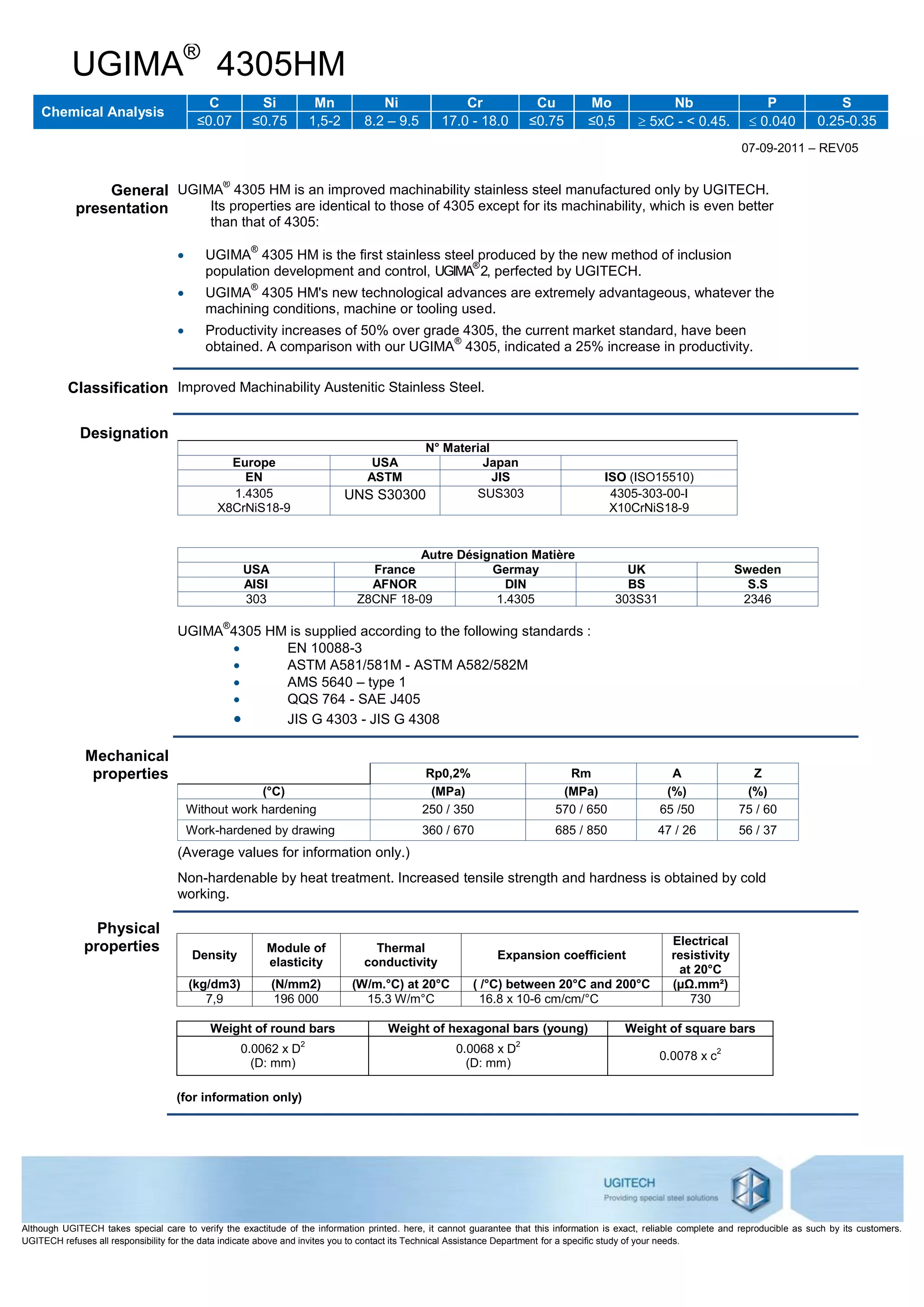

This document provides information on UGIMA® 4305HM, an improved machinability austenitic stainless steel. It includes the chemical composition, standards, mechanical properties, physical properties, corrosion resistance, machinability, welding, heat treatment, forging, and available product forms. Although UGIMA takes care to verify the information, it cannot guarantee exactness and refuses responsibility for the data.