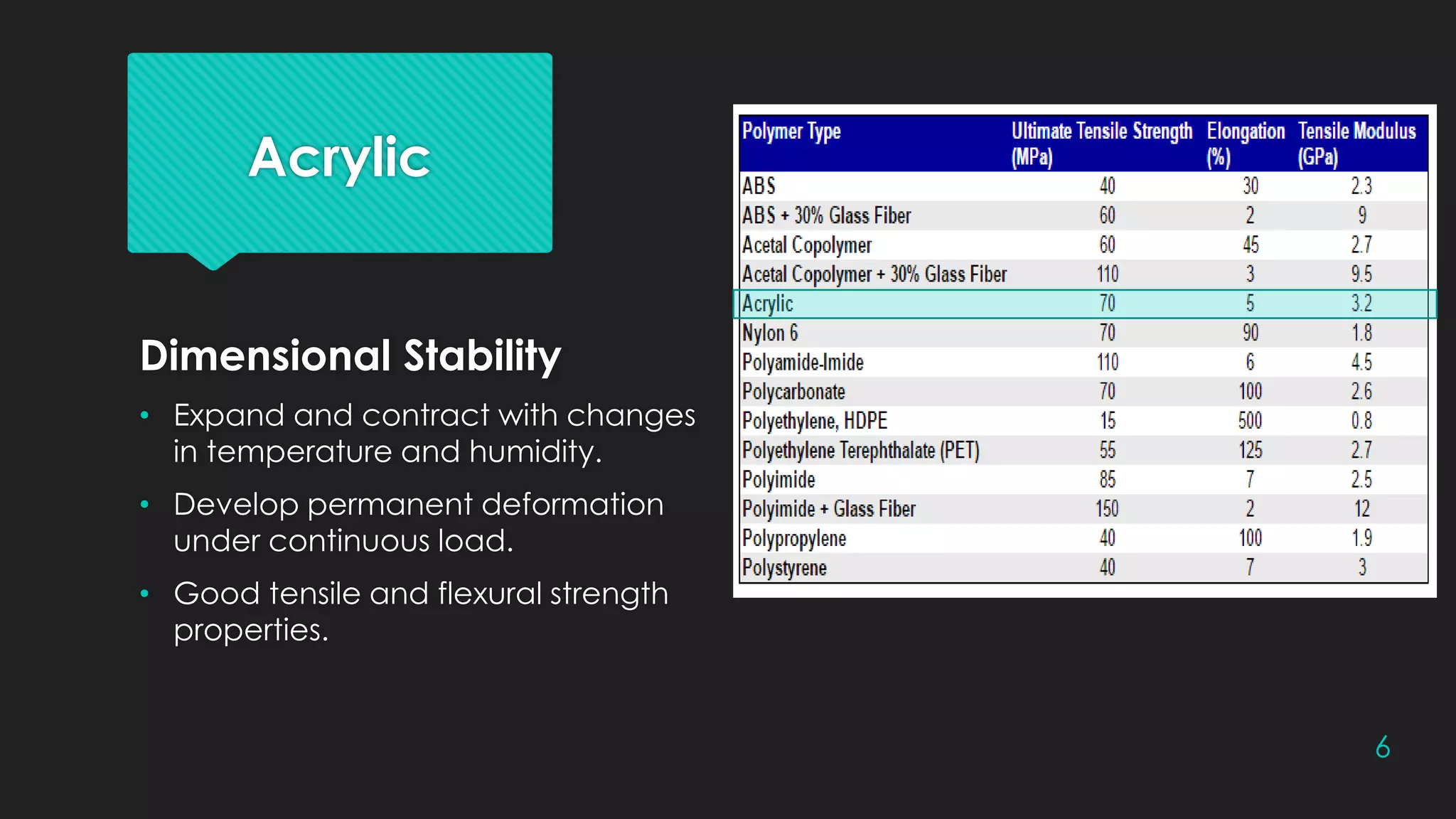

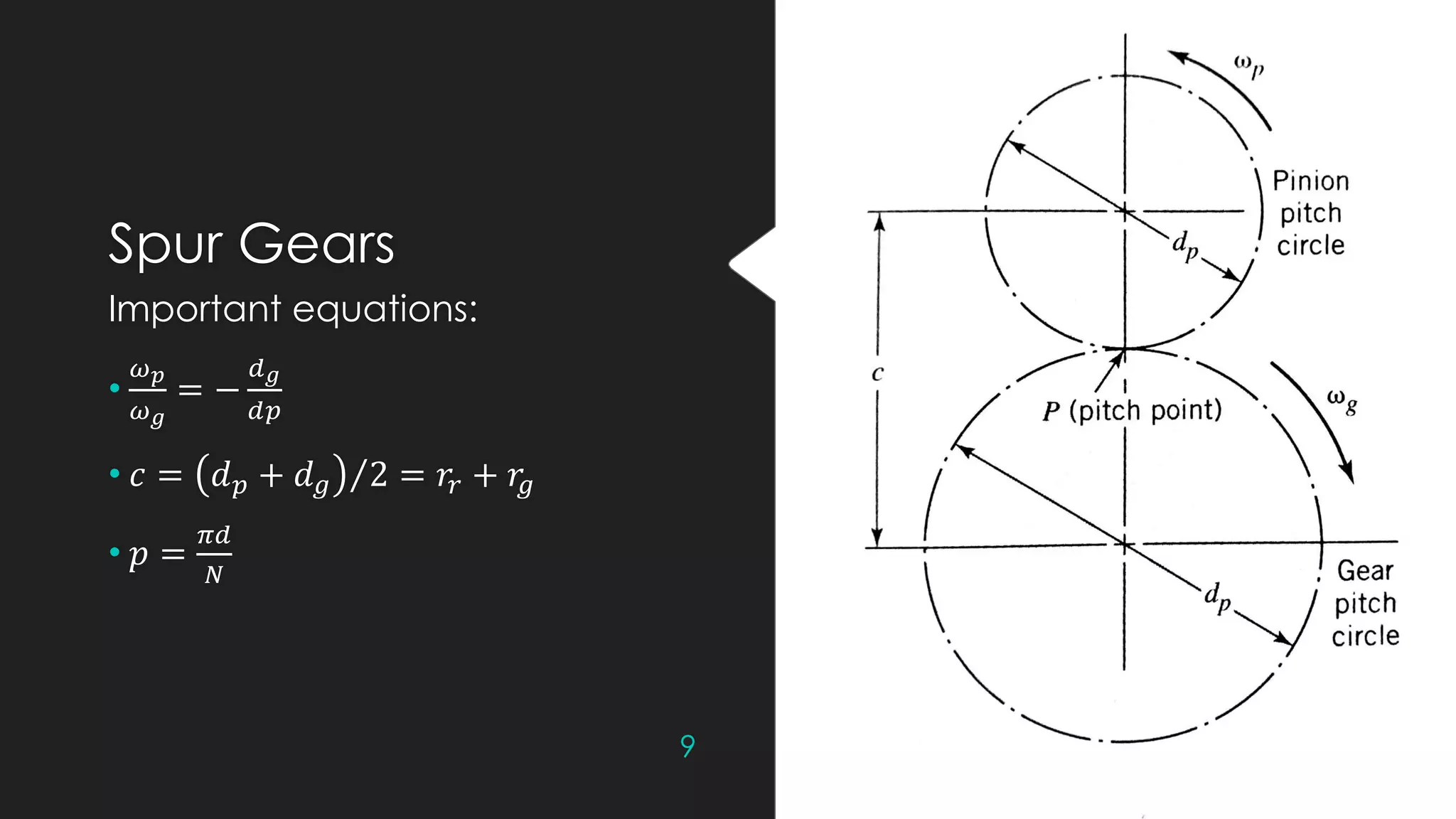

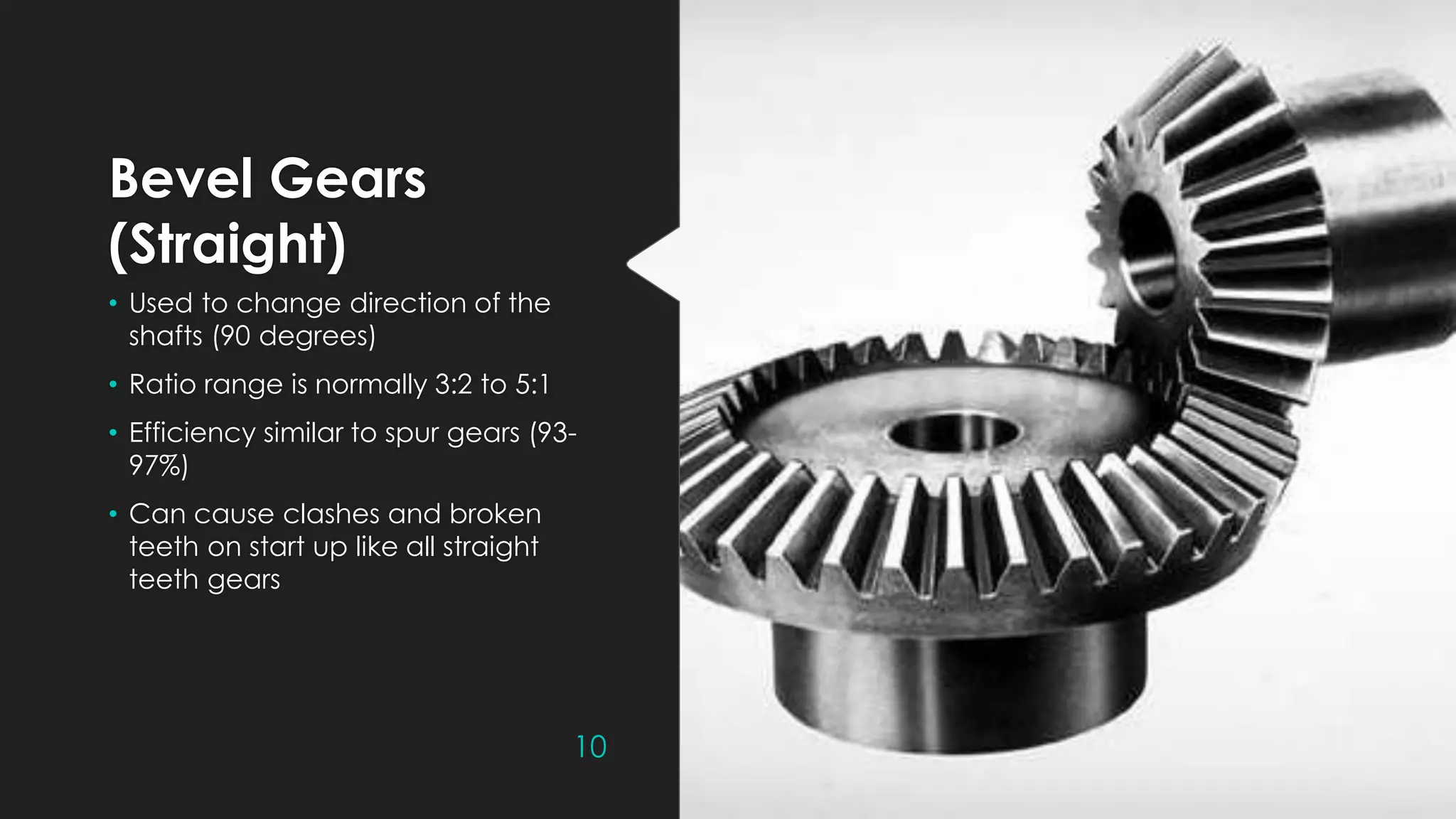

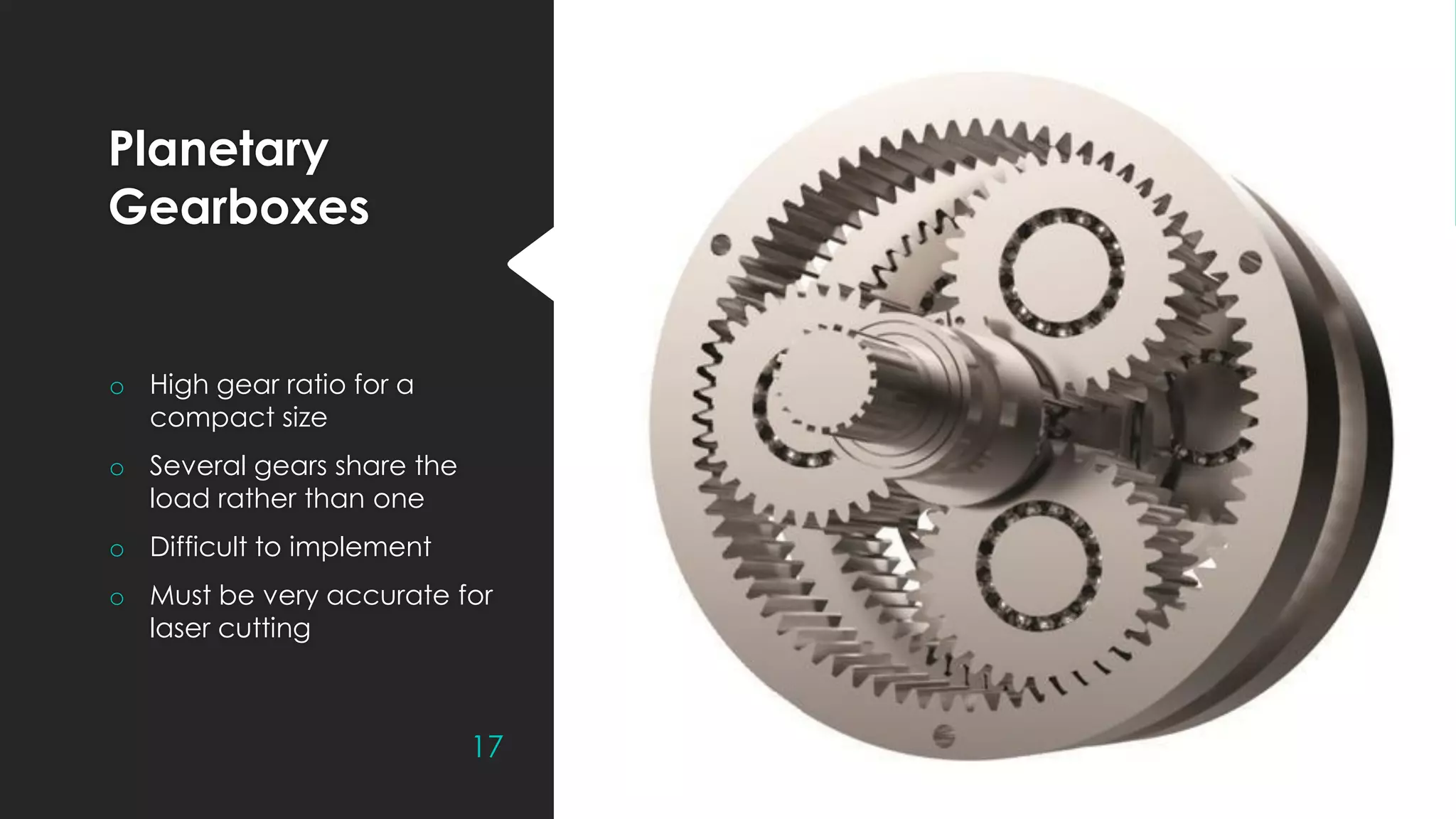

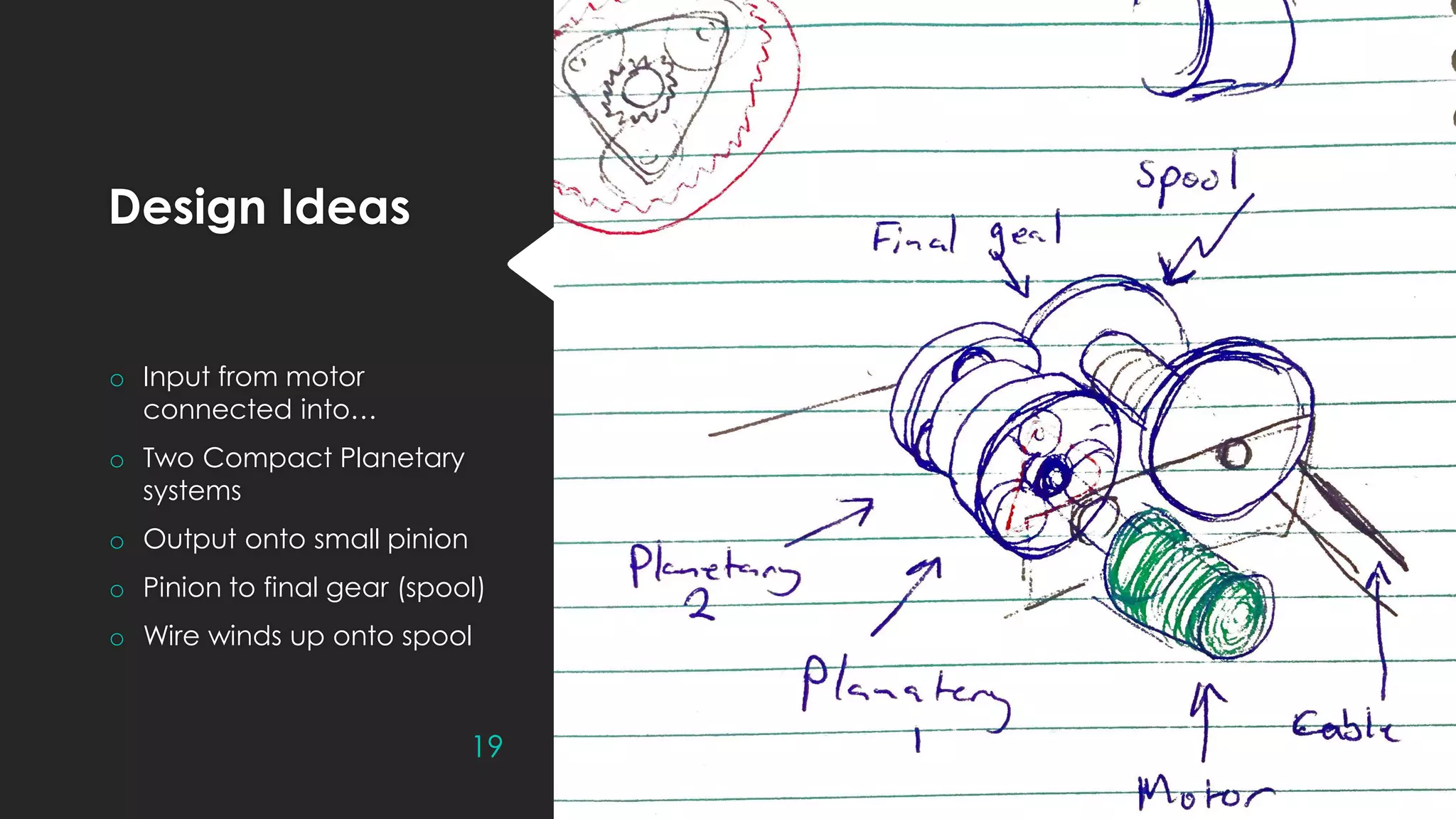

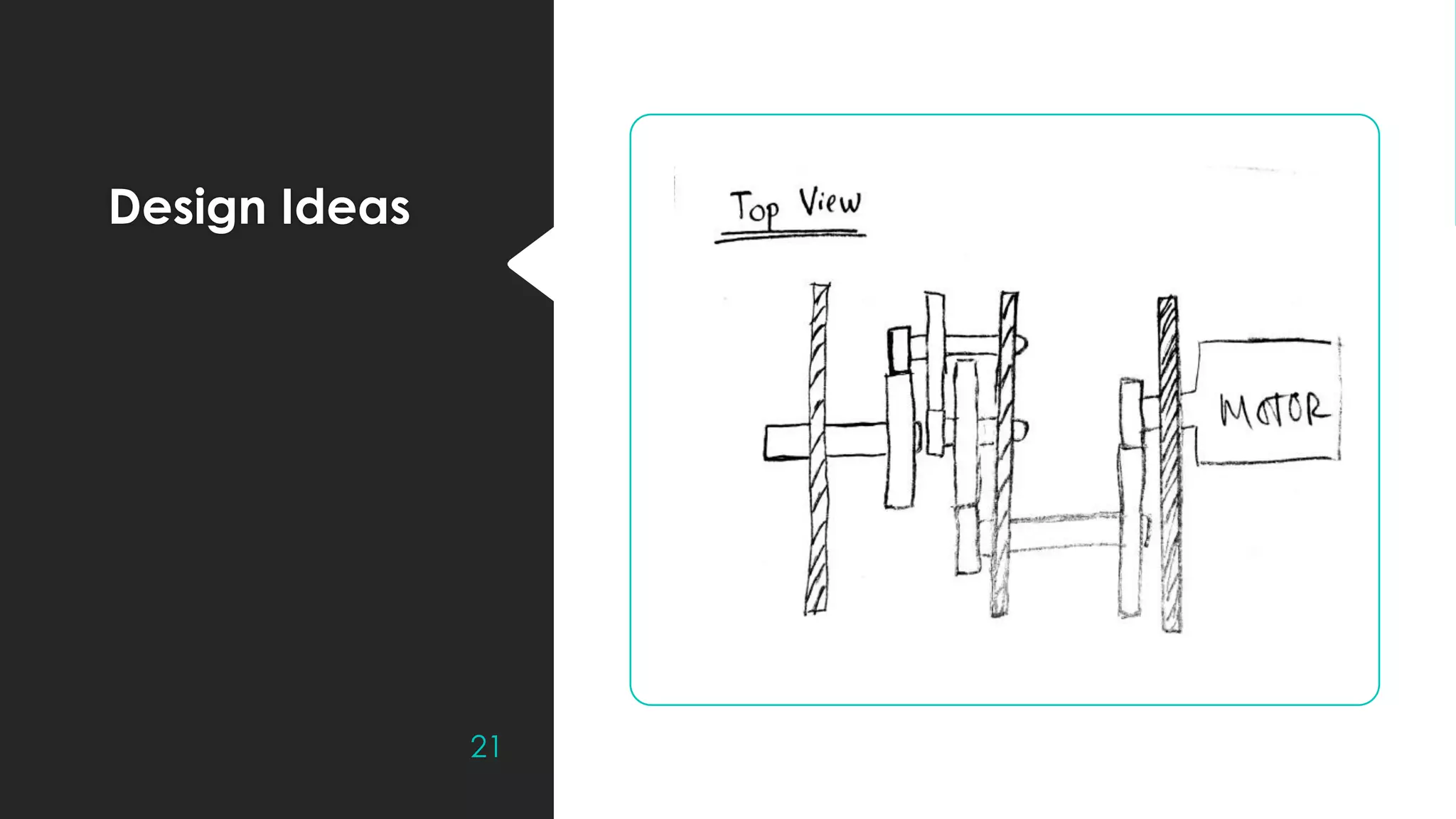

This document discusses the design of a gearbox for a project to move a 10kg weight up a 1m long, 0.725m high ramp. It considers various gearbox types including spur gears, bevel gears, worm gears, cycloid gears, helical gears, hypoid gears, and planetary gearboxes. It provides details on the performance criteria for the gearbox as well as research on materials, gear types, and practical gearbox designs. The proposed design uses two compact planetary gear systems connected to a final gear and spool to wind up wire and move the weight up the ramp.