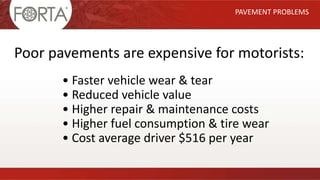

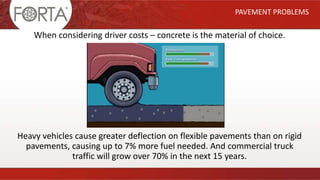

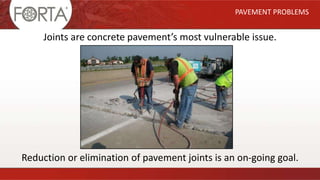

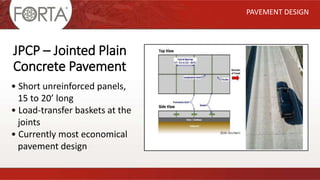

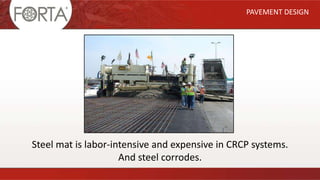

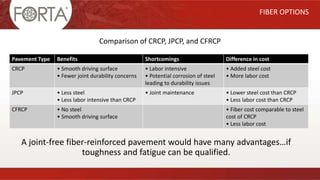

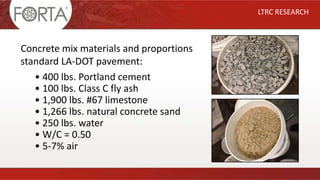

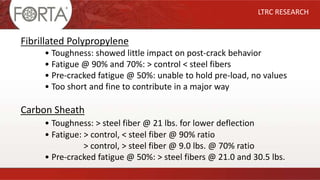

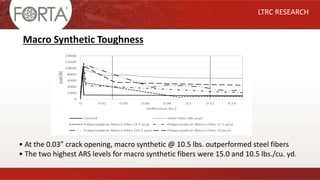

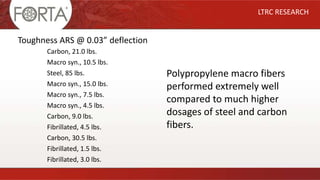

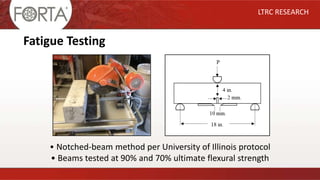

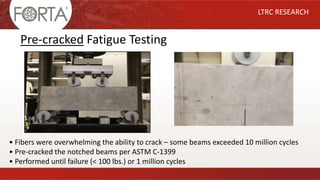

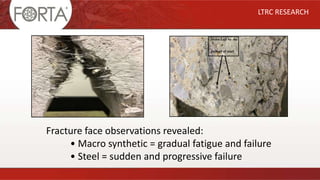

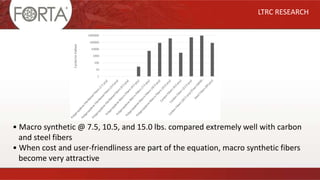

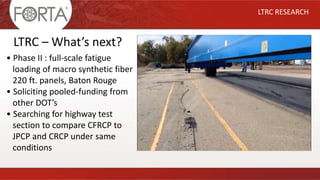

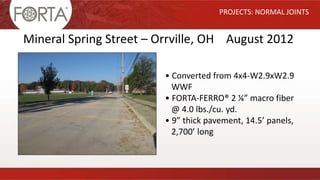

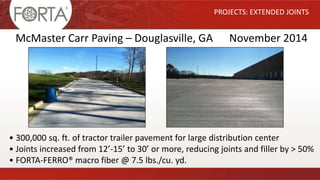

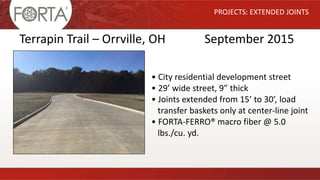

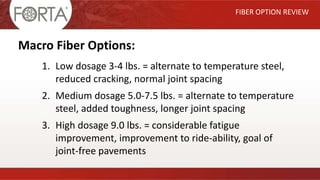

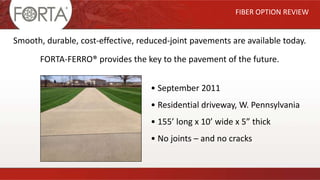

This presentation discusses fiber reinforced concrete (FRC) pavements. It provides an overview of pavement problems like joints, different pavement designs including jointed reinforced concrete pavement (JRCP) and continuously reinforced concrete pavement (CRCP), and fiber options at different dosages. It summarizes research conducted by the Louisiana Transportation Research Center (LTRC) evaluating fatigue and toughness of FRC. The research found that macro synthetic fibers at dosages of 7.5-10.5 lbs/cu yd provided benefits over steel fibers. It concludes with summaries of several pavement projects using FRC with normal joint spacing.