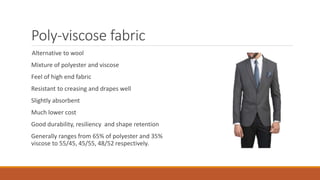

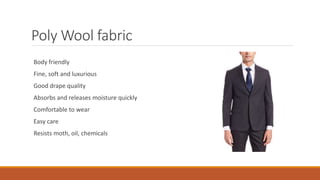

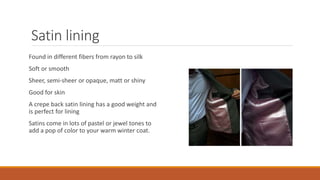

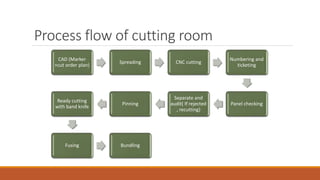

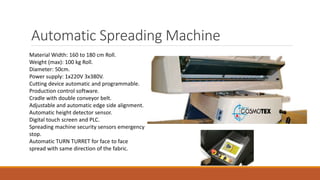

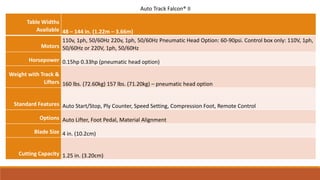

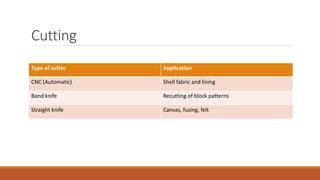

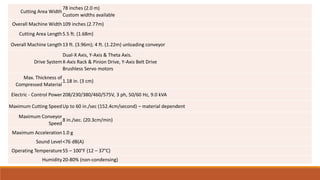

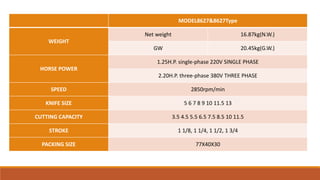

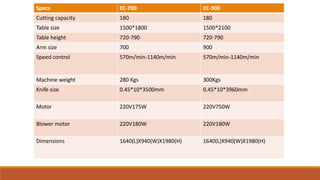

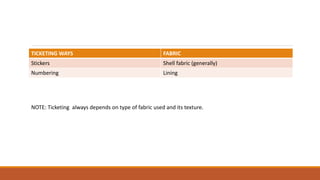

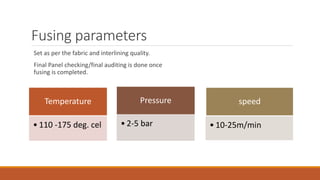

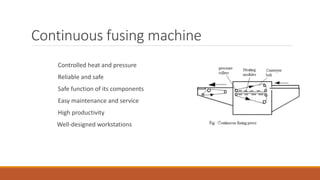

The document provides a comprehensive overview of materials and processes involved in garment manufacturing, specifically focusing on fabric types used for formal jackets, including polyester, viscose, and wool blends. It details the characteristics of various linings and interlinings, their advantages, and the techniques involved in cutting and fusing fabric to ensure proper garment construction. Additionally, it outlines machinery specifications for cutting and spreading fabrics, emphasizing the importance of quality control throughout the production process.