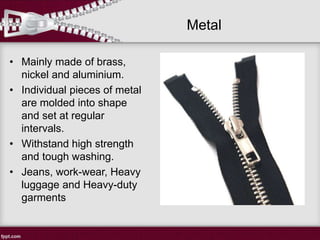

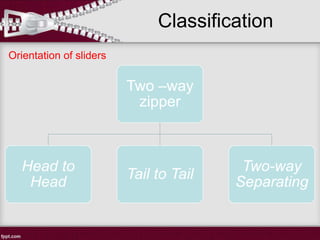

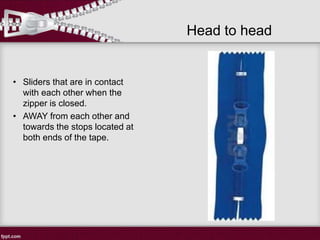

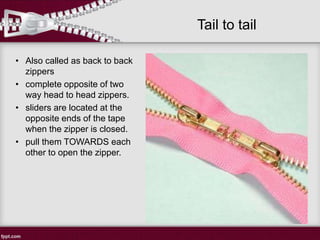

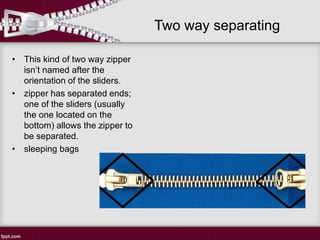

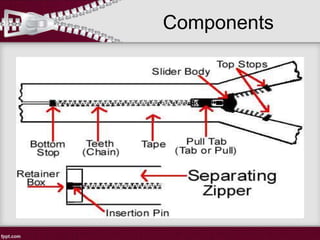

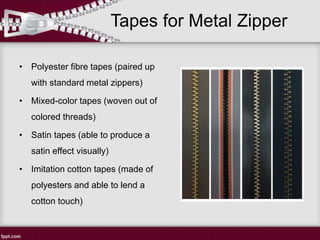

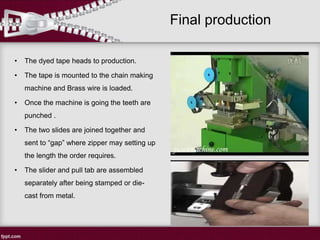

The document provides a comprehensive overview of zipper manufacturing, including its history, types, classification, and components involved in the manufacturing process. It highlights important patents related to zipper innovation and offers care tips for maintaining zippers. Additionally, the document includes acknowledgments to mentors and contributors involved in the research and project completion.