This document provides details about the Ford Pinto case study, including:

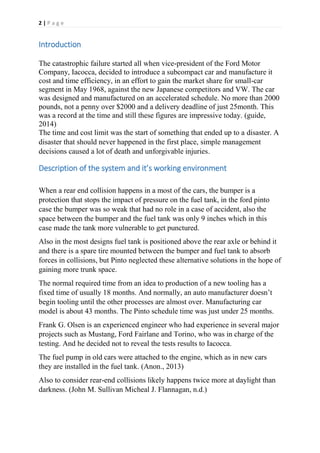

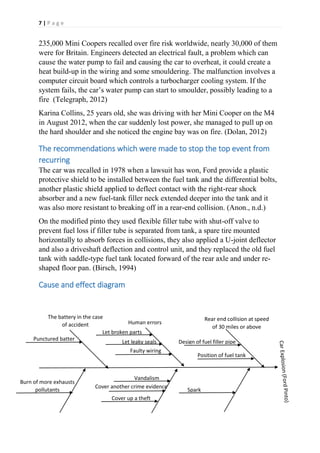

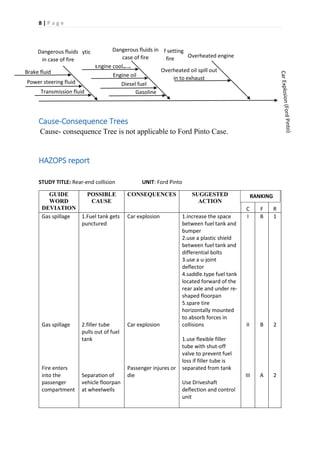

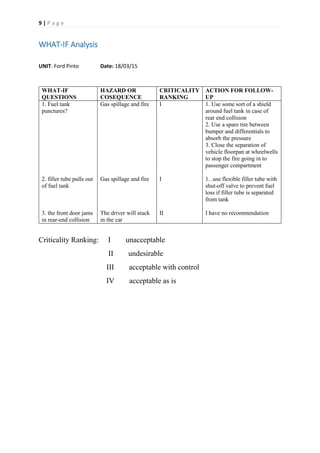

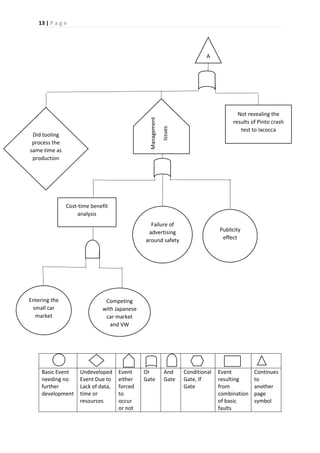

1. The Ford Pinto was designed and manufactured on an accelerated schedule to meet cost and time constraints, which compromised safety testing and design features.

2. Low-speed rear-end crash testing revealed the fuel tank was vulnerable to puncture due to its location behind the rear axle and proximity to protruding bolts, but Ford failed to implement recommended safety modifications.

3. Two catastrophic failures occurred when Pintos were rear-ended and their fuel tanks ruptured, resulting in fires that killed the drivers. Ford was aware of the design flaw from internal testing but conducted a cost-benefit analysis that determined not fixing it would

![14 | P a g e

References

Anon., 1973. Ford 'pinto' Memo. [Online]

Available at: http://web1.calbaptist.edu/dskubik/pinto.htm

[Accessed 18 march 2015].

Anon., 2013. AutoEducation. [Online]

Available at: http://www.autoeducation.com/autoshop101/fuel.htm

[Accessed 21 February 2015].

Anon., n.d. RCRSD. [Online]

Available at: http://www.rcrsd.com/news/mark-robinson-ford-pinto/

[Accessed 16 March 2015].

Birsch, D., 1994. THE FORD PINTO CASE: A Study in Applied Ethics, Business, and Technology.

NewYork: State University of NewYork .

Boyce, D., n.d. The Ford Pinto Case. [Online]

Available at: http://fordpintoethics.webs.com/

[Accessed 3 March 2015].

Dowie, M., 1977. Mother Jones. [Online]

Available at: http://www.motherjones.com/politics/1977/09/pinto-madness

[Accessed 8 February 2015].

Engineer, T., 2006. ENGINEERING.COM. [Online]

Available at: http://www.engineering.com/Library/ArticlesPage/tabid/85/ArticleID/166/Ford-

Pinto.aspx

[Accessed 3 march 2015].

guide, A. E. o. c., 2014. howstuffworks. [Online]

Available at: http://auto.howstuffworks.com/1971-1980-ford-pinto.htm/printable

[Accessed 23 february 2015].

John M. Sullivan Micheal J. Flannagan, n.d. RISK OF FATAL REAR-END COLLISIONS, Michigan:

University of Michigan.

LaPine, C., 2013. howstuffworks. [Online]

Available at: http://auto.howstuffworks.com/car-driving-safety/accidents-hazardous-conditions/10-

causes-of-car-fires.htm#page=5

[Accessed 16 March 2015].

Leggett, C., 1999. THE VALUATION OF LIFE AS IT APPLIES TO THE NEGLIGENCY ARGUMENT. [Online]

Available at: http://users.wfu.edu/palmitar/Law&Valuation/Papers/1999/Leggett-pinto.html

[Accessed 23 february 2015].

Nerdster, P., 2013. Pn. [Online]

Available at: http://professornerdster.com/lee-iacocca-dont-elaborate-much-on-your-deadly-

mistakes/

[Accessed 20 February 2015].

Schwartz, G. T., 1991. THE MYTH OF THE FORD PINTO CASE. Volume 43:1013, pp. 1013-1068.](https://image.slidesharecdn.com/b2ffebac-02f5-4fd4-85c2-a4ff6274079e-150506060013-conversion-gate02/85/ford-pinto-case-study-15-320.jpg)

![15 | P a g e

sherefkin, R., 2003. Automotive News. [Online]

Available at: http://www.autonews.com/article/20030616/SUB/306160770/lee-iacoccas-pinto:-a-

fiery-failure

[Accessed 16 March 2015].

Telegraph, T., 2012. MINI Cooper S Recall, s.l.: Telegraph.

Wojdyla, B., 2011. popular machines. [Online]

Available at: http://www.popularmechanics.com/cars/a6700/top-automotive-engineering-failures-

ford-pinto-fuel-tanks/

[Accessed 6 February 2015].](https://image.slidesharecdn.com/b2ffebac-02f5-4fd4-85c2-a4ff6274079e-150506060013-conversion-gate02/85/ford-pinto-case-study-16-320.jpg)