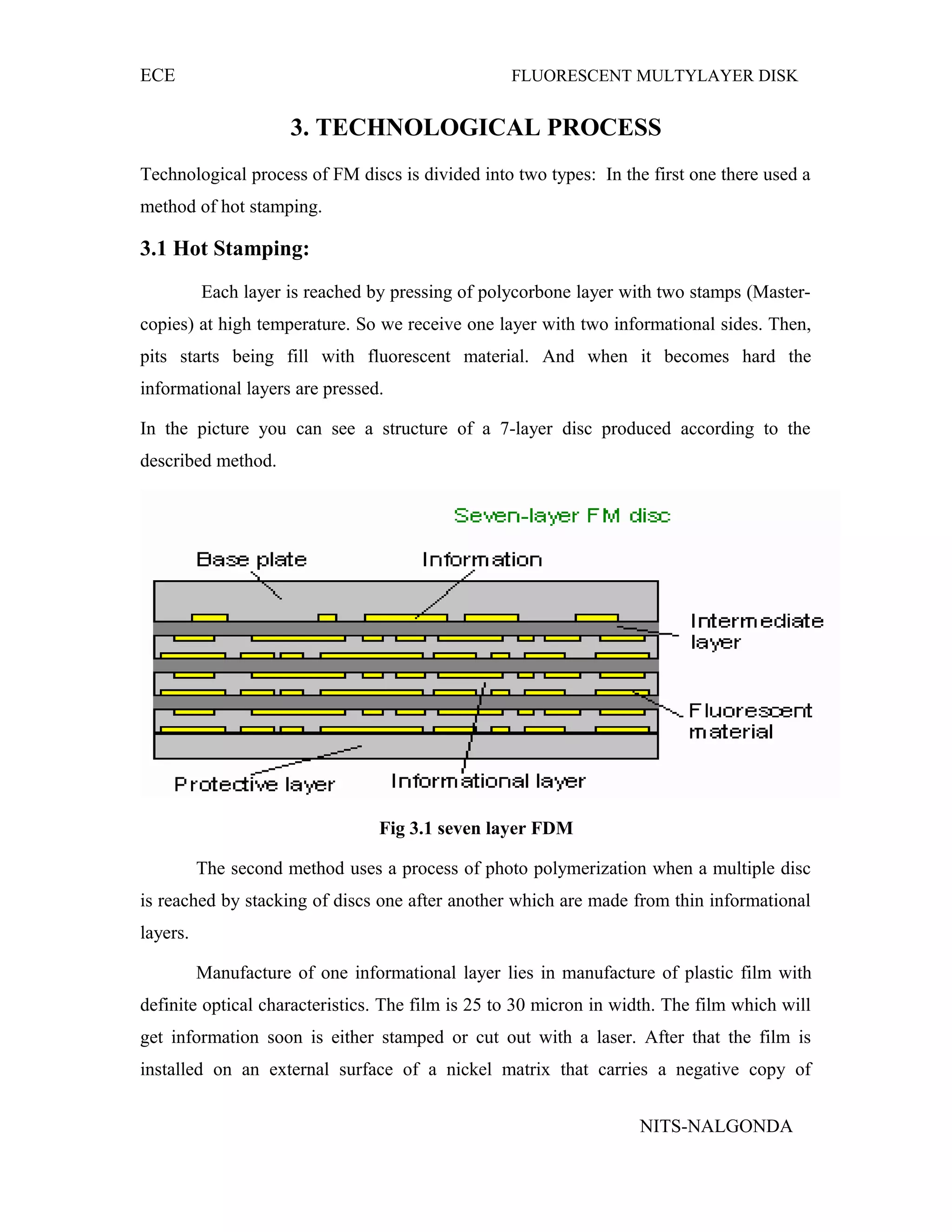

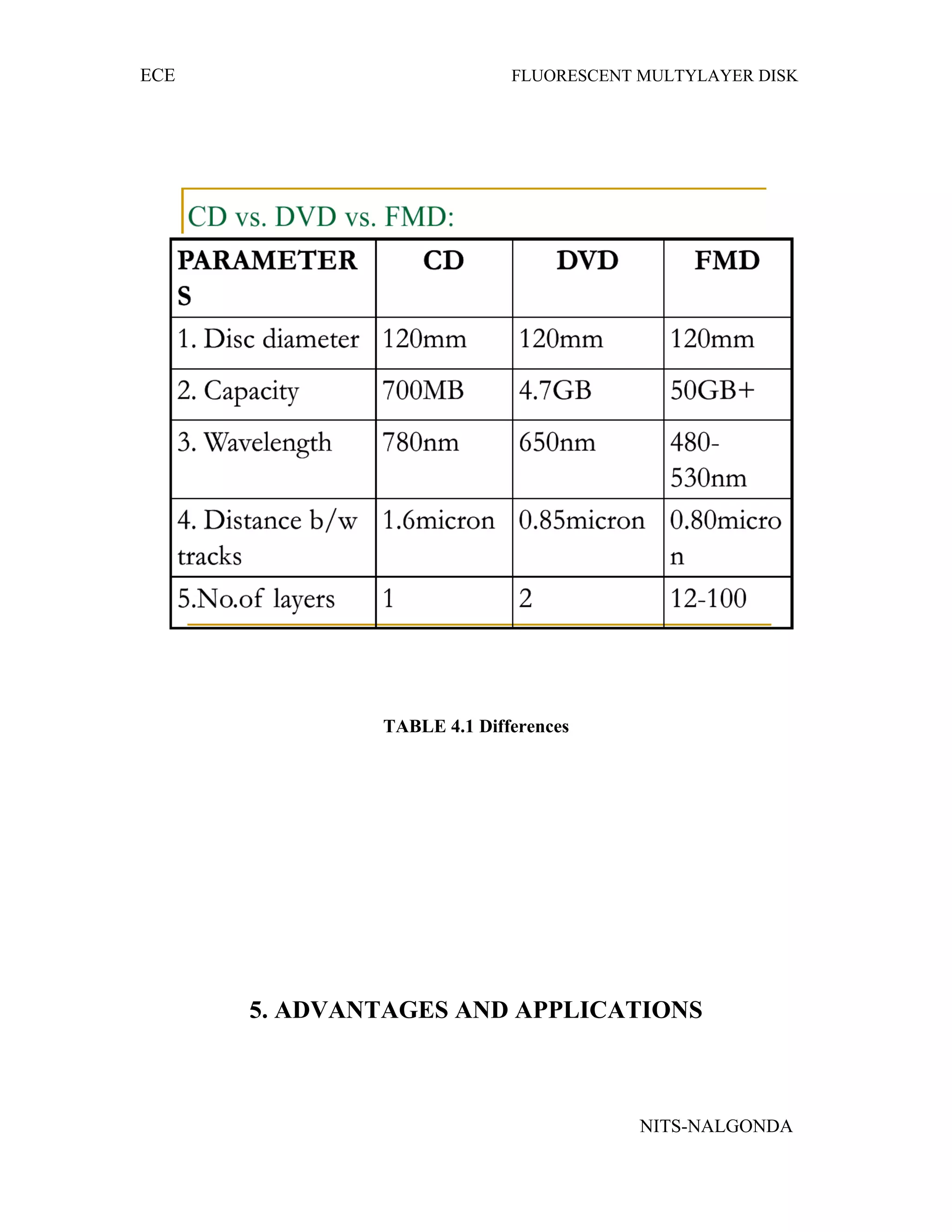

Fluorescent Multilayer Disk (FMD) technology allows for over 100 layers in a disk by using fluorescent materials that emit different wavelengths of light for each layer. This overcomes limitations of reflective DVDs which degrade after only a few layers. FMD prototypes demonstrated 50GB storage using red lasers, with plans for 140GB using red lasers and over 1TB using blue lasers. FMD works by filling pits with fluorescent materials that convert laser light to a distinct emitted wavelength, allowing layers to be read through the transparent disk. The main limitation is thickness, not interference like in DVDs.