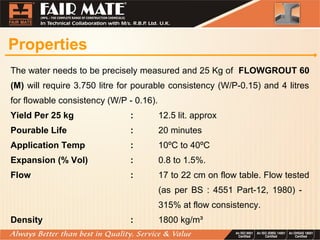

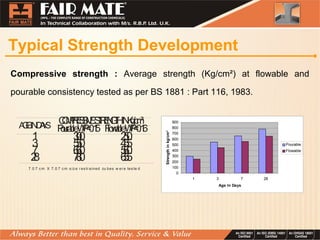

This document describes Flowgrout 60(M), an ultra high strength, free flowing, non-shrink cementitious grout. It is a pre-packaged, single component grout that requires only the addition of water. It is chloride free and expands slightly to ensure it fills all gaps without shrinkage. It is suitable for grouting under heavy machinery and can withstand vibration and impact loads. It has a long work time and excellent adhesion to concrete and steel. Typical compressive strengths are over 650kg/cm2 after 7 days.