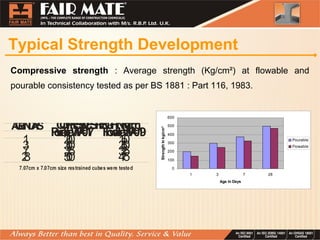

Flowgrout 40 is a single-pack, high-strength, free-flowing, non-shrink grout that is chloride-free and contains no metallic content. It is pre-packaged to ensure consistent materials and only requires the addition of water. Flowgrout 40 expands to offset shrinkage and ensure retention of original volume. It is easy to place and self-levels, making it suitable for grouting bolt pockets, base plates, and machinery foundations. Strength tests show compressive strengths of 137 kg/cm2 at 28 days for a pourable consistency and 150 kg/cm2 at 28 days for a flowable consistency.