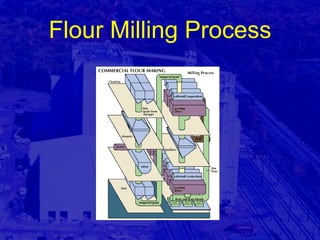

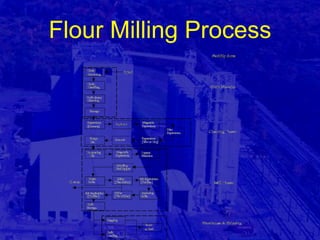

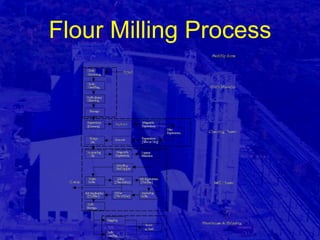

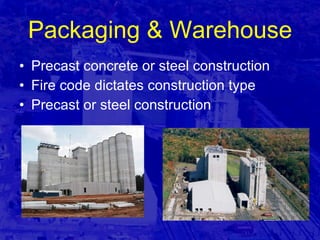

This document discusses key considerations for planning and life safety in flour milling facilities. It covers regulatory codes around occupancy, construction type, height and area restrictions. Grain storage, cleaning towers, tempering bins and mills often use slipformed concrete construction. The document outlines the flour milling process and notes facilities must plan for flexible layouts and changing technology. Life safety focuses on OSHA, FDA, NFPA codes around equipment access, building envelope, fire protection and loads in mill structures. Sanitary construction aims to allow durable, cleanable surfaces throughout facilities.