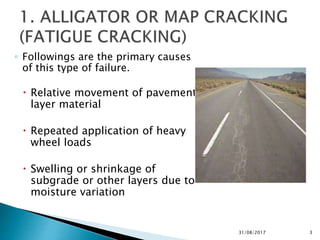

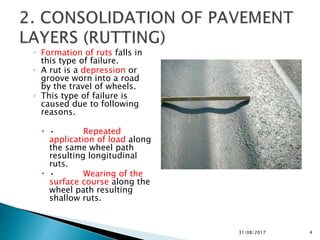

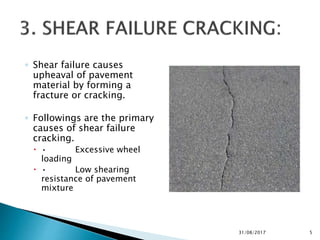

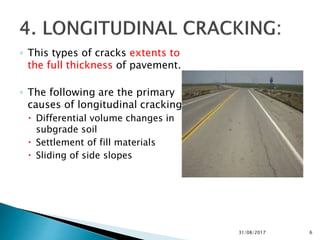

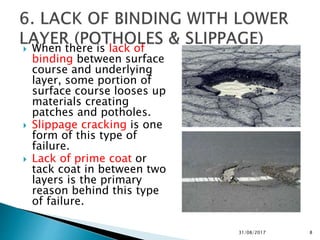

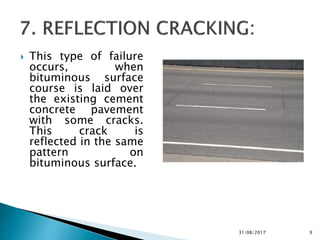

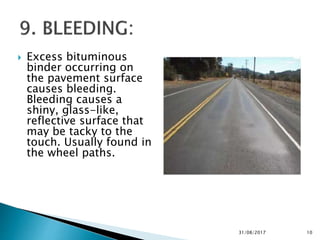

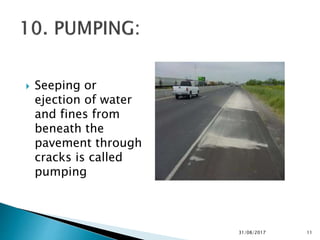

The document discusses various types of failures that can occur in flexible pavements, including alligator cracking, rutting, shear failure cracking, longitudinal cracking, frost heaving, lack of binding between layers, reflection cracking, bleeding, and pumping. It describes the primary causes of these failures as being relative movement between pavement layers, repeated heavy wheel loads, and swelling/shrinkage of subgrade layers from moisture variation. Specific failures like rutting and shear cracking are also explained in more detail.